Pressure ozone generator

An ozone generator and ozone technology, applied in the direction of ozone preparation, ozone preparation by discharge method, oxygen/ozone/oxide/hydroxide, etc., can solve the troublesome operation of moving equipment, short effective sterilization time, increased operating costs, etc. problem, to achieve the effect of prolonging the effective sterilization time of ozone mist, enhancing the sterilization and disinfection ability, safe and reliable operation and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

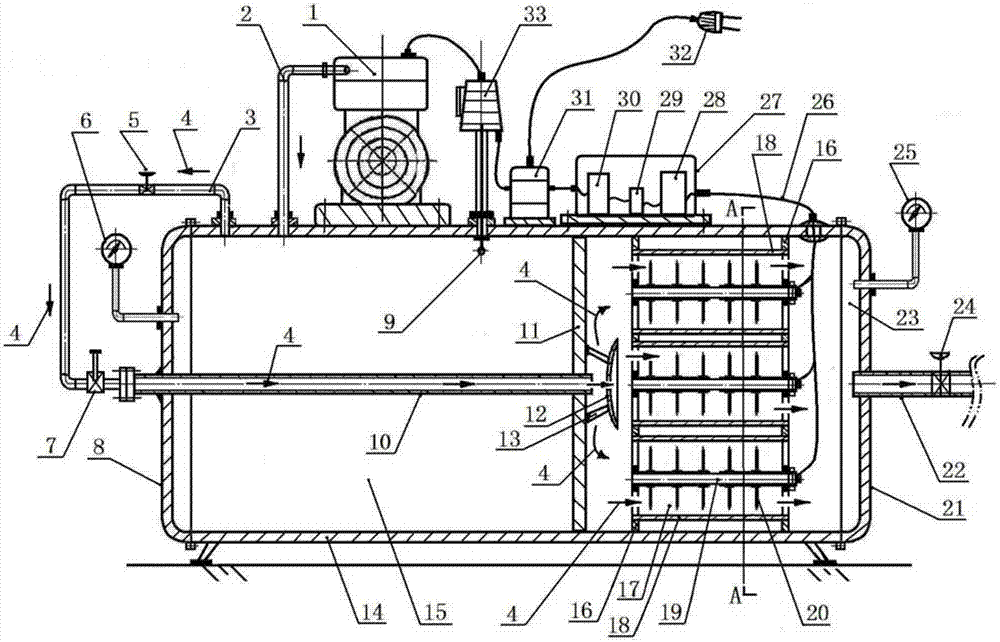

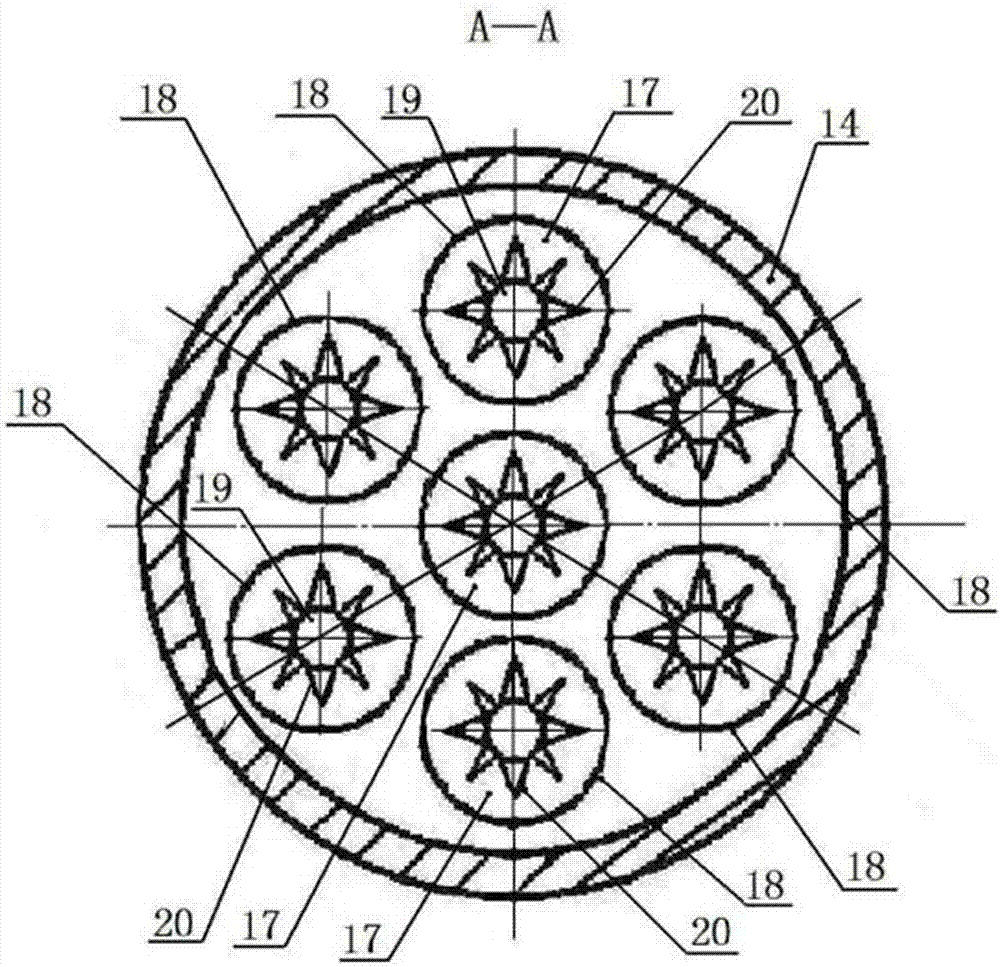

[0019] A pressurized ozone generator, which mainly consists of an air storage tank 14, an air compressor 1 installed on the air storage tank 14, a junction box 31, a pressure switch 33, a pressure sensor 9, an electric field power supply 27 and a group of electric field steel cylinders 18 structure, a partition plate 11 is set in the air storage tank 14 to be divided into a compressed air chamber 15 and an ozone chamber 23. It is equipped with a high-pressure air pipe 2, a high-pressure output pipe 3, a pressure sensor 9, and a pressure switch 33 communicated with the compressed air chamber 15. The high-pressure air pipe 2 is connected to the compressed air output nozzle of the air compressor 1; The high-pressure output pipe 3 is connected to the intake pipe end of the horizontal air pipe 10, and the high-pressure output pipe 3 is equipped with a shut-off va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com