Antibacterial and antiviral formaldehyde-removing antifouling agent and preparation method thereof, glazed tile and preparation method thereof

A formaldehyde-removing and anti-virus technology, used in anti-fouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of short anti-bacterial and anti-virus time, easy to explode, etc., and achieve longer effective sterilization time , the effect of prolonging the effective sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A method for preparing an antifouling Formaldehyde antibacterial and antiviral agents, for the preparation of the above-mentioned antibacterial and antiviral Formaldehyde antifouling agent, comprising the steps of:

[0054] (1) The modified STELLERITE, stabilized chlorine dioxide solution and a silver diammine hydroxide solution was formulated for comparison uniformly mixed and dried to obtain a solid modified STELLERITE silver chloride powder;

[0055] (2) the modified STELLERITE solid silver chloride powder, hydroxy-terminated polydimethylsiloxane, an aqueous aliphatic polyurethane dispersant formulated and mixed in a ratio of formaldehyde to give an antifouling antibacterial and antiviral agents.

[0056] In one embodiment of the present invention, the specific step (1) is, after the modified STELLERITE, stabilized chlorine dioxide solution and a silver diammine hydroxide solution was mixed in a ratio according to the formula, sufficiently stirred for 24 hours, allowed t...

Embodiment 1-5

[0072] An antibacterial antiviral Formaldehyde antifouling agent, the antifouling agent raw material comprising 10 to 20 parts of the modified STELLERITE solid silver chloride powder, 50 to 70 parts hydroxyl-terminated dimethylsiloxane, 10 ~ 20 parts of an aqueous aliphatic polyurethane and 1 to 2 parts dispersing agent; wherein the fineness modified STELLERITE solid silver chloride fine powder of 1000 mesh;

[0073] Wherein the modified STELLERITE solid silver chloride powder, 50 to 70 parts by preparing stabilized chlorine dioxide solution, and 5 to 20 parts of a silver diammine hydroxide solution obtained from 10 to 30 parts of the modified Stellerite. Wherein a modified modified STELLERITE sulfuric Stellerite.

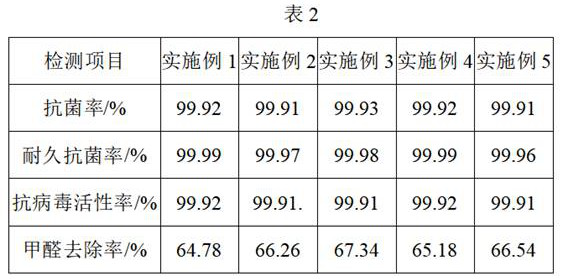

[0074] Specifically, the starting material Formulation Example 1 to 5 such antifouling agents shown in Table 1:

[0075]

[0076] Preparation process of the present embodiment, antibacterial and antiviral Formaldehyde antifouling agent comprising the steps of:

[007...

Embodiment 6

[0087] Antibacterial and antiviral same as in embodiment 6-8 Formaldehyde antifoulant formulation of raw materials than in Example 2, except that the embodiment glazed Examples 6 to 8 are non-parabolic glazed tiles, which spraying Example 6 antibacterial and antiviral manner to formaldehyde coated surface polishing antifouling agents of the non-glazed tiles; antifouling agent coated surface of Example 7 using brushing manner antibacterial and antiviral formaldehyde polishing non-glazed tiles in this embodiment; Example 8 immersion embodiment will formaldehyde antibacterial and antiviral surface of the non-polishing antifouling agent is applied in the glazed tiles.

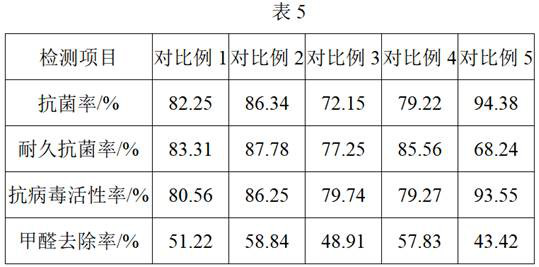

[0088] With the above method, prepared Formaldehyde glazed antibacterial and antiviral, antibacterial antiviral obtained Formaldehyde glazed JC / T 897-2014 "Antibacterial Properties Antibacterial Ceramics" and ISO 21702-2019 "The plastics and other non-porous surface antiviral activity assay "two detection methods, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com