Anaerobic ammonium oxidation-based two-stage artificial rapid infiltration system and its start-up method

A technology of artificial rapid percolation and anaerobic ammonium oxidation, applied in chemical instruments and methods, aerobic and anaerobic process treatment, aerobic process treatment, etc., can solve the problem of low total nitrogen removal rate and reduce the reaction process , save the reaction volume, save the effect of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described with reference to the drawings.

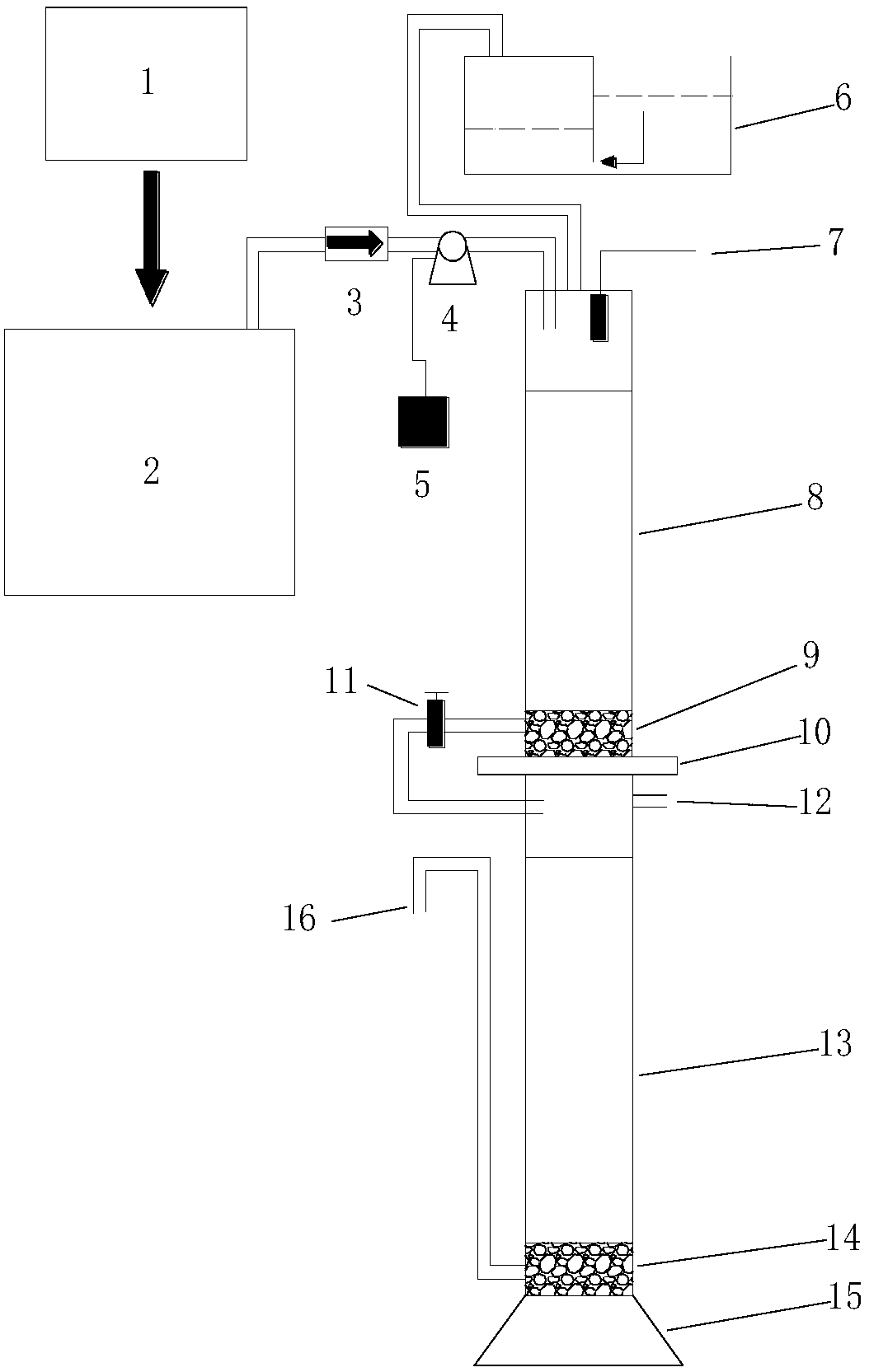

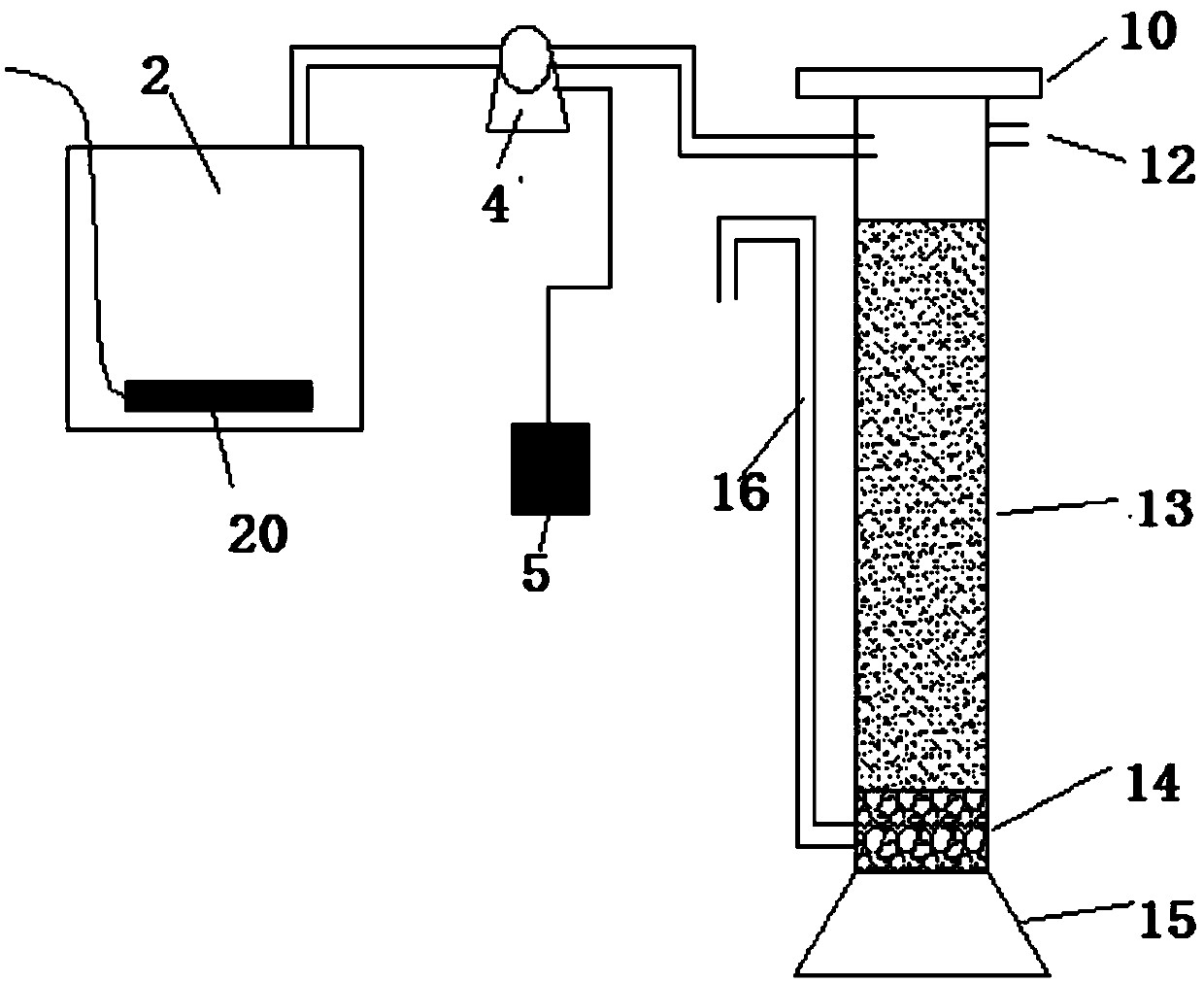

[0018] Such as figure 1 As shown, the two-stage manual rapid infiltration system based on anaerobic ammonia oxidation includes a distribution tank 2, a U-shaped tank 6. The outlet pipe of the distribution tank 2 is connected with a one-way valve 3 and a water pump 4; the water pump 4 is controlled by a relay 5. control;

[0019] The outlet pipe of the distribution tank 2 and the U-shaped water tank 6 are respectively connected with the facultative oxygenation section sand filter layer 8 through pipelines; the facultative oxygenation section sand filter layer 8 is equipped with an online dissolved oxygen meter 7; the bottom of the facultative oxygenation section sand filter layer 8 is gravel Layer 9, gravel layer 9 has a facultative section outlet pipe, and there is a stop valve 11 on the facultative section outlet pipe; below the gravel layer 9 is the water-proof bottom pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com