Manufacturing method of zirconia ceramic large-scale thin-wall device

A technology of zirconia ceramics and a manufacturing method is applied in the manufacture of large-scale thin-walled zirconia ceramic devices, the preparation of ceramic flakes, and the fields of large-scale thin-walled devices, so as to achieve the effects of reducing grinding amount, reducing total cost and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

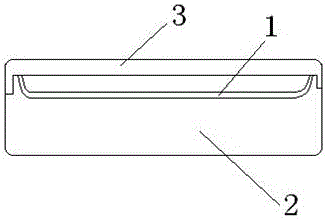

[0028] as attached figure 1 As shown, a method for manufacturing a zirconia ceramic mobile phone back cover, the zirconia ceramic mobile phone back cover is a thin-walled device, and the injection molding method is used to produce the zirconia ceramic mobile phone back cover, with zirconia powder containing a stabilizer as the main body , mix the zirconia powder and the organic carrier according to the weight ratio of 100:10-30; obtain the injection molding material after banburying, and then use the injection molding process to make the zirconia ceramic mobile phone back cover body 1, and use the injection molding process at the same time Make the support mold 2 and cover plate 3 with the same injection material, then put the zirconia ceramic mobile phone back cover body 1 into the support mold 2, and then cover the cover plate 3 on the zirconia ceramic mobile phone back cover blank Body 1, and then carry out the secondary degreasing treatment of soaking oil and heating degr...

Embodiment 2

[0042] The basic method of the second embodiment is the same as that of the first embodiment, a zirconia ceramic thin-walled plate, and the manufacturing method of the zirconia ceramic thin-walled plate is a zirconia ceramic thin-walled device produced by an injection molding method to contain a stabilizer The zirconia powder is the main body, and the zirconia powder and the organic carrier are mixed in a weight ratio of 100:10-30; the injection molding material is obtained after banburying, and then the green body is made by the injection molding process, and the support is made by the injection molding process The mold and cover plate, then put the zirconia ceramic thin-walled plate blank into the support mold, and then cover the cover plate on the zirconia ceramic thin-walled plate blank, and then carry out the secondary degreasing of soaking oil and heating degreasing together treatment, and finally a zirconia ceramic thin-walled plate with no deformation and high performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com