Soft glycol-modified polyethylene terephthalate (PETG) resin composition and extruded article comprising the same

A technology of PET-G and resin composition, which can solve problems such as the difficulty in making soft films or sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the proposed embodiments, but the shown embodiments are illustrative examples for clearly understanding the present invention, and the present invention is not limited thereto.

[0020] Hereinafter, the technical configuration of the present invention will be described in detail based on preferred embodiments.

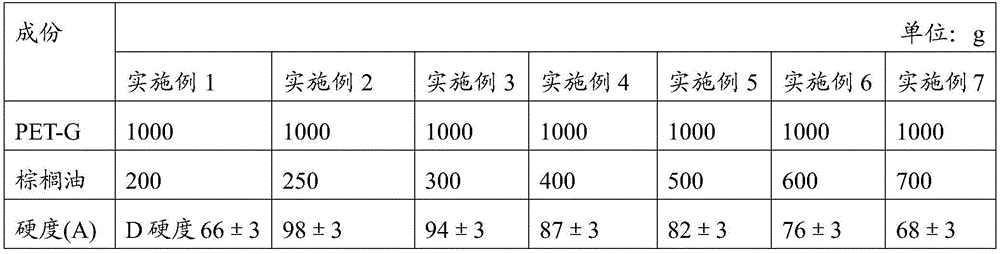

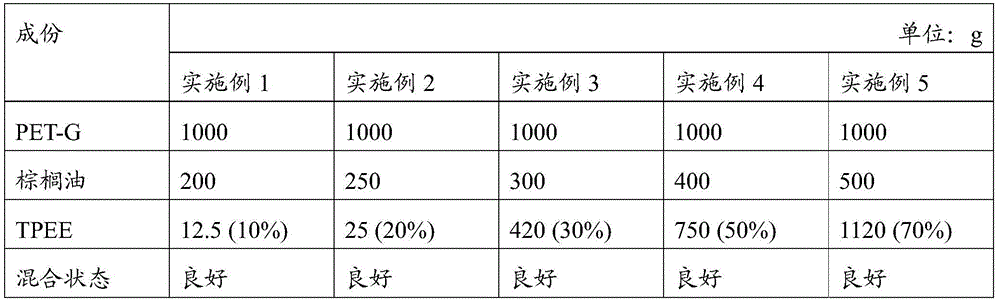

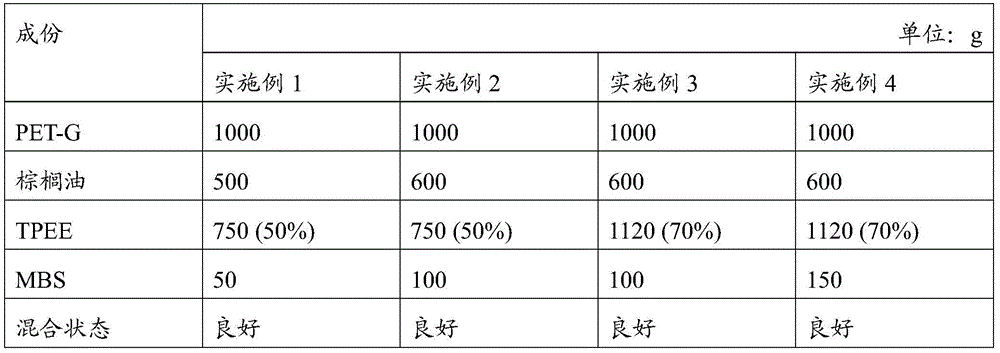

[0021] The present invention relates to a method of mixing vegetable oil in PET-G to reduce hardness, using TPEE (Thermoplastic polyester elastomer) resin and MBS (methyl methacrylate butadienestyrene) resin to ensure physical properties, adding processing aids to improve physical properties and processability, and to manufacture environmentally friendly Soft PET-G resin composition for permanent film and sheet, and extruded soft film or sheet formed by extruding the soft PET-G resin composition.

[0022] In the present invention, PET-G resin is firstly selected as the base resin as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com