Three-layer co-extrusion high-temperature-resistant glue blocking release film and production process thereof

A high-temperature release film, three-layer co-extrusion technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve problems such as silicone oil precipitation, contamination of circuit boards, etc. The effect of good fluidity and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

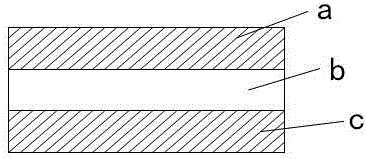

[0035] Embodiment 1: as figure 1As shown, a three-layer co-extruded high temperature resistant adhesive release film, the mass fraction of each component in the outer film is as follows: PBT polybutylene terephthalate 49%, PA66 polyamide resin 26%, AX8900 resin 5% and glass fiber reinforced plastics 20%; the mass fraction of each component in the resist filling film is as follows: PBT polybutylene terephthalate 68%, EVA ethylene-vinyl acetate copolymer 16%, LDPE low density polyethylene Ethylene 11%, AX8900 resin 3% and stabilizer 2%; In the high-temperature release film of the present invention, the thickness of the release upper layer film and the release type lower layer film is 30% of the total thickness of the release film, and the thickness of the resist filling film The thickness is 40% of the total thickness of the release film.

Embodiment 2

[0036] Embodiment 2: as figure 1 As shown, a three-layer co-extruded high temperature resistant adhesive release film, the mass fraction of each component in the outer film is as follows: PBT polybutylene terephthalate 51%, PA66 polyamide resin 24%, AX8900 resin 5% and glass fiber reinforced plastics 20%; the mass fraction of each component in the resist filling film is as follows: PBT polybutylene terephthalate 72%, EVA ethylene-vinyl acetate copolymer 14%, LDPE low density polyethylene Ethylene 9%, AX8900 resin 3% and stabilizer 2%; In the high-temperature release film of the present invention, the thickness of the release upper film and the release lower film are 30% of the total thickness of the release film, and the thickness of the resist filling film The thickness is 40% of the total thickness of the release film.

Embodiment 3

[0037] Embodiment 3: as figure 1 As shown, a three-layer co-extruded high temperature resistant adhesive release film, the mass fraction of each component in the outer film is as follows: PBT polybutylene terephthalate 50%, PA66 polyamide resin 25%, AX8900 resin 5% and glass fiber reinforced plastics 20%; the mass fraction of each component in the resist filling film is as follows: PBT polybutylene terephthalate 70%, EVA ethylene-vinyl acetate copolymer 15%, LDPE low density polyethylene Ethylene 10%, AX8900 resin 3% and stabilizer 2%; In the high-temperature release film of the present invention, the thickness of the release upper layer film and the release type lower layer film is 30% of the total thickness of the release film, and the thickness of the resist filling film The thickness is 40% of the total thickness of the release film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com