Two aerospace turbofan engines

A turbofan engine, aerospace technology, applied in the direction of engine function, machine/engine, rocket engine device, etc., can solve the problems of uneconomical, affecting flight altitude and endurance, and high consumption, so as to save fuel and facilitate development and application , good effect of technology inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

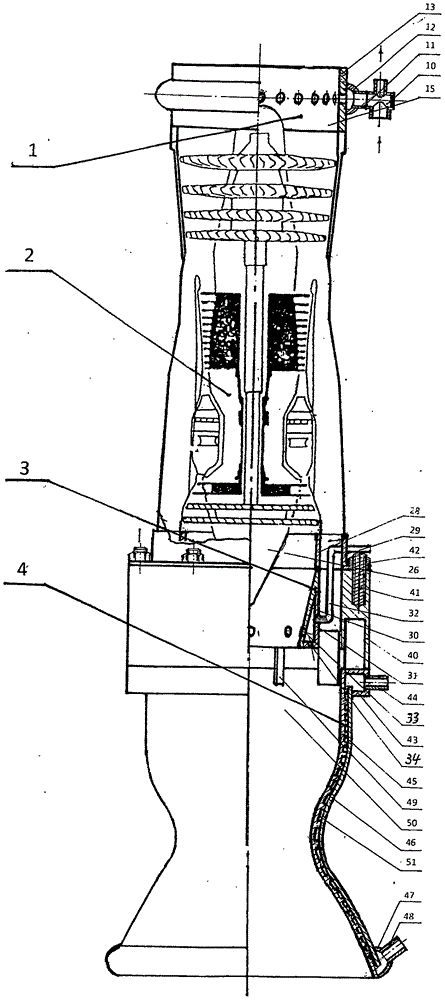

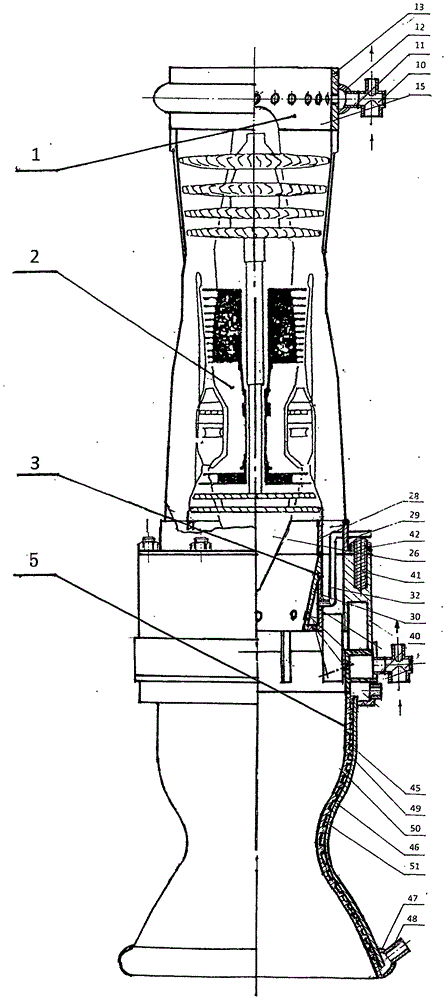

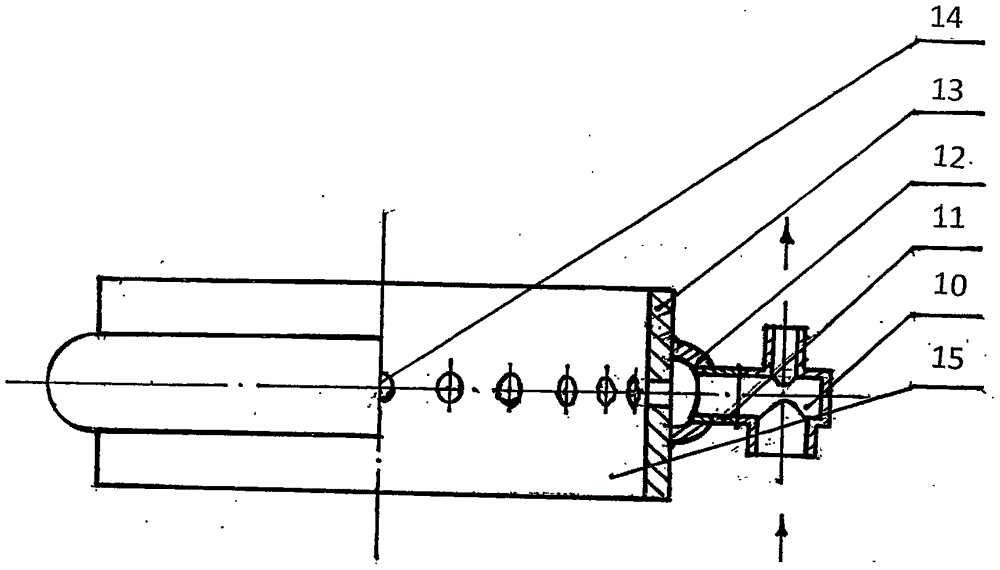

[0035] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 It is the preferred embodiment of two kinds of aerospace turbofan engines of the present invention.

[0036] Such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 7As shown, the first aerospace turbofan engine of the present invention is composed of an inlet rich oxygen injection assembly 1, a slightly modified main structure 2, an afterburner middle part 3 and an afterburner outer ring part 4. The oxygen-enriched injection assembly 1 includes an oxygen-enriched tee pipe 10, an oxygen-enriched inlet pipe 11, an oxygen-enriched concentrator 12, and an oxygen-enriched injection ring 13. Minor changes to the main structure 2 include an outer wall of the air inlet 20 and a low-pressure compressor 21. , high-pressure compressor 22, main combustion chamber 23, high-pressure turbine 24, low-pressure turbine 25, center tail nozzle 26, outer duct outer wall 27, thickened outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com