Intermittent fluidization thermal energy and chemical energy storage and release reaction device and working method

A reaction device and fluidization technology, which is applied in the field of medium and high temperature thermal energy storage, can solve the problems of rarely seen application of high temperature thermochemical energy storage, etc., so as to avoid uneven reaction heat release, make up for unevenness, and reduce industrial pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The above content has fully explained the specific structure of the present invention. The specific implementation will be described in detail below in conjunction with the accompanying drawings, taking the application of the present invention to a 450°C, 0.25MW energy storage and conversion device as an example. Enforcement and protection are not limited thereto.

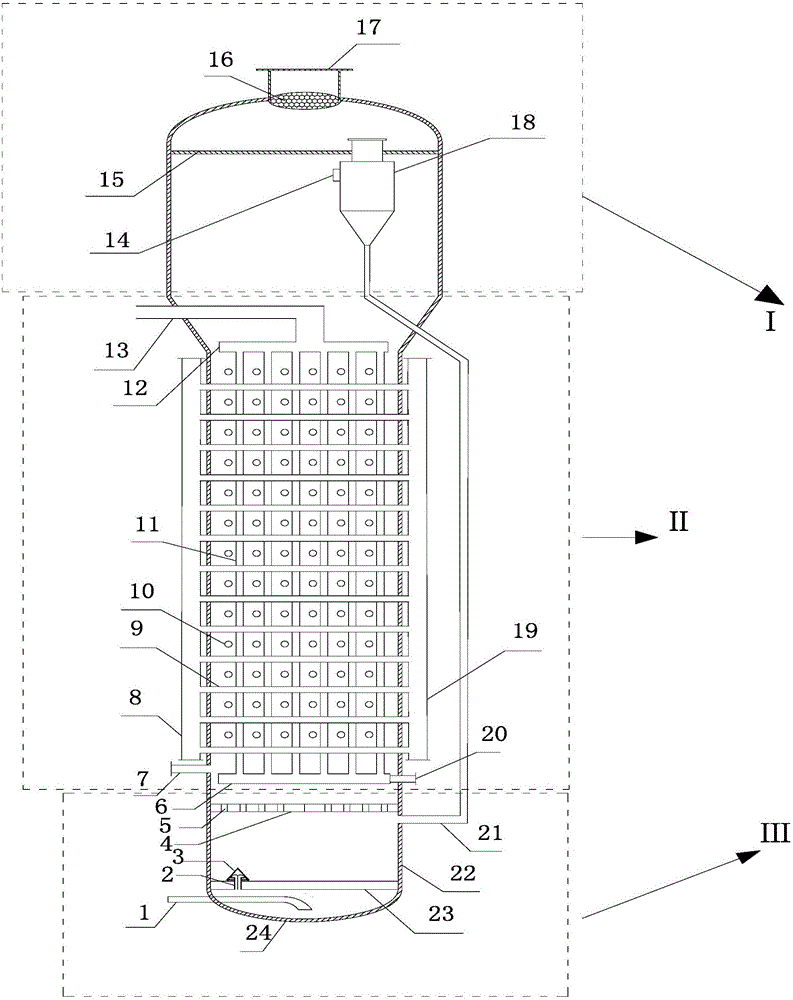

[0040] Such as figure 1 As shown, an intermittent fluidized thermal energy and chemical energy storage and release reaction device includes three parts: fluidization system III, heat exchange system II and gas-solid separation system I. The three systems are all in a fluidized bed inside the device.

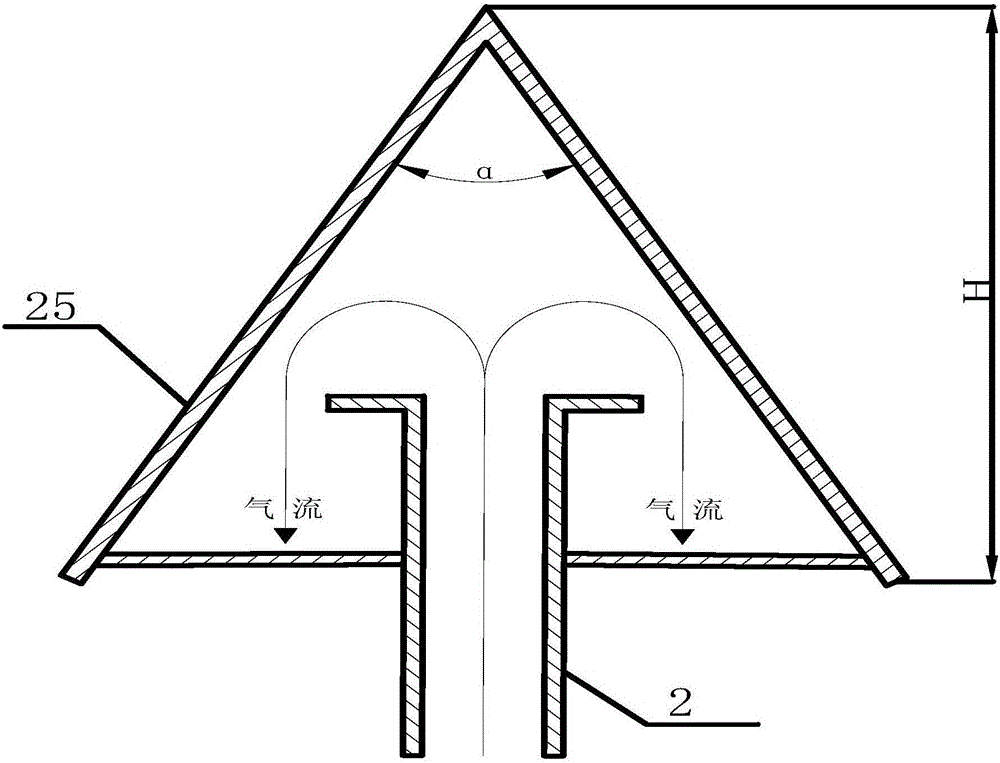

[0041] Among them, the fluidization system is at the bottom of the device, the elbow 1 is welded to the gas pre-distribution device 24, and the high-pressure oxygen enters the reaction device through the elbow 1, and after interacting with the gas pre-distribution device 24, it contacts the gas flow distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com