Out-of-plane displacement measurement system and method based on projected moiré method

A technology of off-plane displacement and projected moiré, applied in the field of optical measurement, can solve the problems of changing the measurement area of the system and low measurement resolution, and achieve the effect of low hardware requirements, high degree of automation, high resolution and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

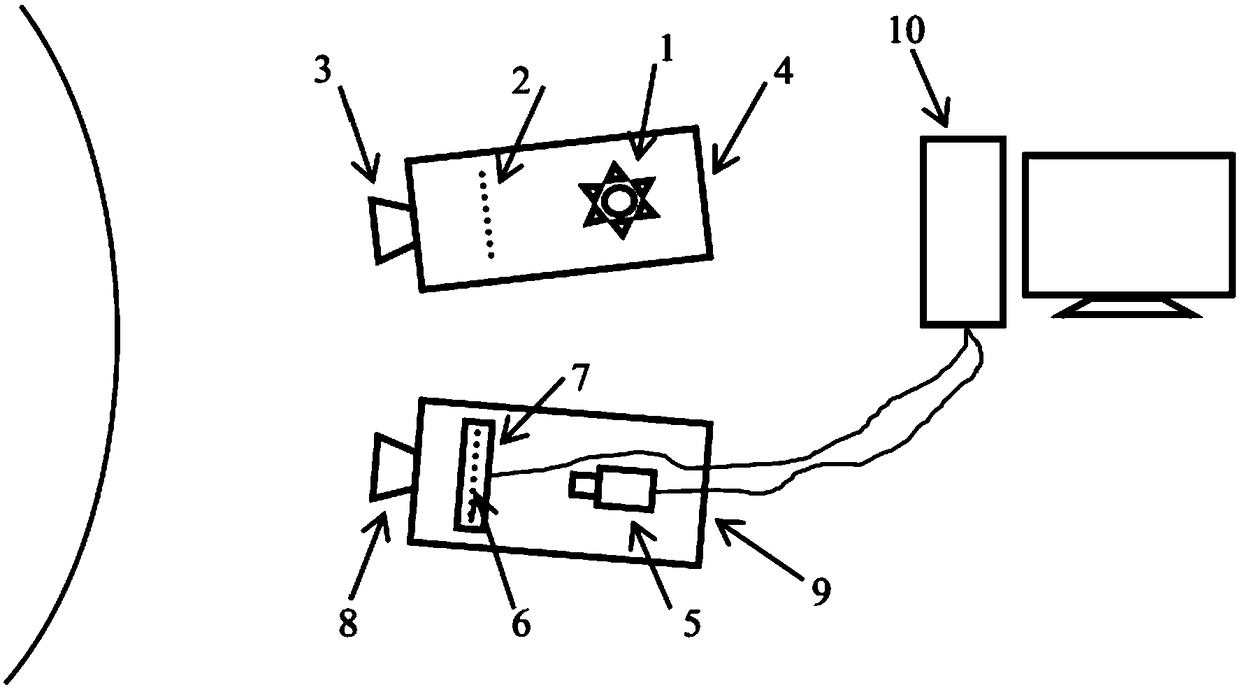

[0028] Such as figure 1 As shown, this embodiment includes: a light source 1, two gratings 2 and 6, two zoom lenses 3 and 8, a CCD camera 5, a phase shift device 7, housings 4 and 9, and an image processing control system 10, wherein: the light source 1. The projection grating 2 and the projection lens 3 are installed in the housing 4 to form a projection system; the CCD camera 5, the reference grating 6, the phase shift device 7 and the imaging lens 8 are installed in the housing 9 to form an image acquisition system; image processing The control system 10 is connected with the phase shifting device 7 and the CCD camera 5 respectively, so as to acquire corresponding moiré fringe images while moving the reference grating 6 to generate a phase shift.

[0029] The light source 1 adopts a halogen lamp white light source, power: 150W.

[0030] The gratings 2 and 6 are machine-engraved transmission gratings, the pitch of which is determined according to the area and resolution req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com