Rapid positioning device and positioning method for optical system test

An optical system and positioning device technology, applied in the field of optical detection, can solve the problems of long preparation time for debugging, waste of time and manpower, etc., and achieve the effects of shortening debugging time, easy replacement, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

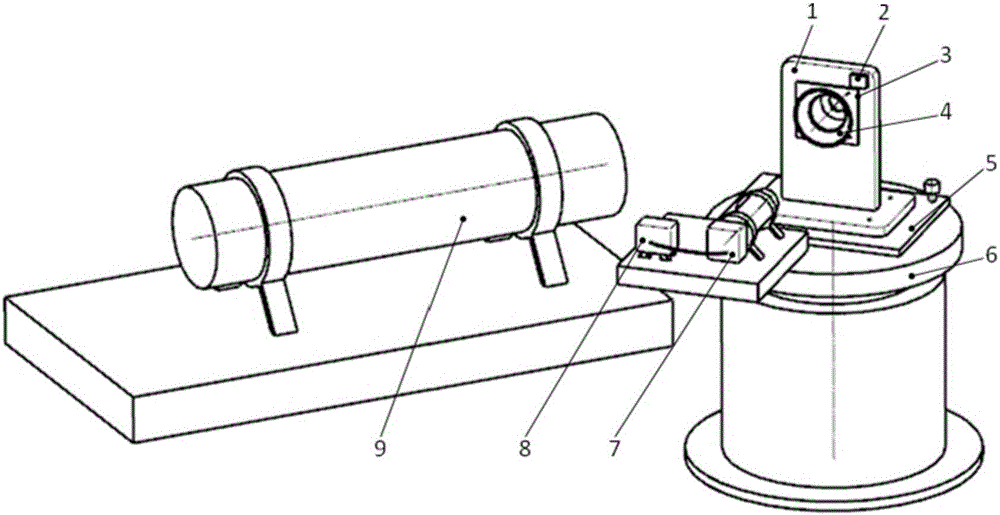

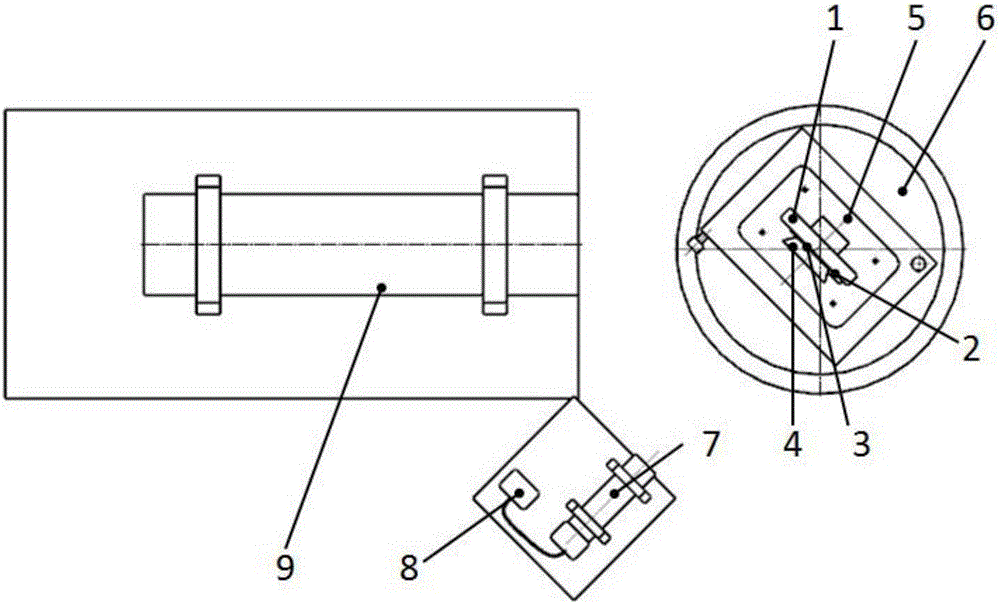

[0033] see figure 1 with figure 2 , provides a schematic diagram of the rapid positioning device for optical system testing of the present invention, the device includes:

[0034] Aiming unit, optical system positioning unit and attitude adjustment unit; Aiming unit comprises self-collimating light pipe 7 and monitor 8; Optical system positioning unit comprises reference plate 1 and reference mirror 2; Attitude adjustment unit comprises two-dimensional adjustment table 5 and single Axis turntable 6; the two-dimensional adjustment table and the reference plate are sequentially arranged on the single-axis turntable from bottom to top; the two-dimensional adjustment table is used to adjust the azimuth and pitch direction of the reference plate. The two-dimensional adjustment table 5 can be adjusted in two directions of azimuth and pitch, and the resolution is better than 1″; the positioning accuracy of the 6-corner position of the single-axis turntable is better than 2″;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com