Preparation method of asphalt mixture sample ultrathin slice for microscopic observation

A technology of asphalt mixture and material flakes, which is applied in the preparation of test samples, analysis materials, sampling, etc., can solve the problems of inability to prepare complete and microcrack-free asphalt mixture ultrathin slices, and achieve resource saving and reduction. Low maintenance cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

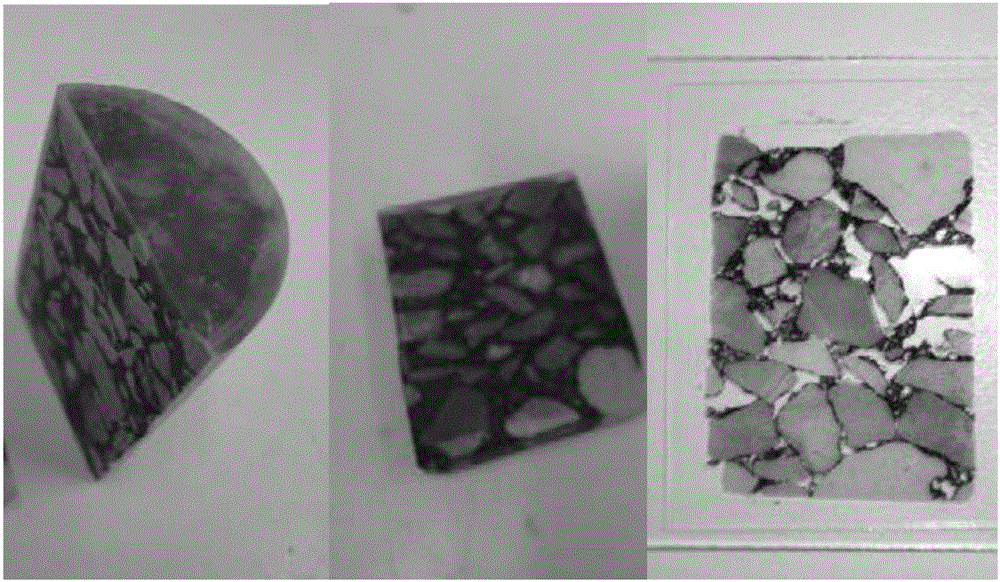

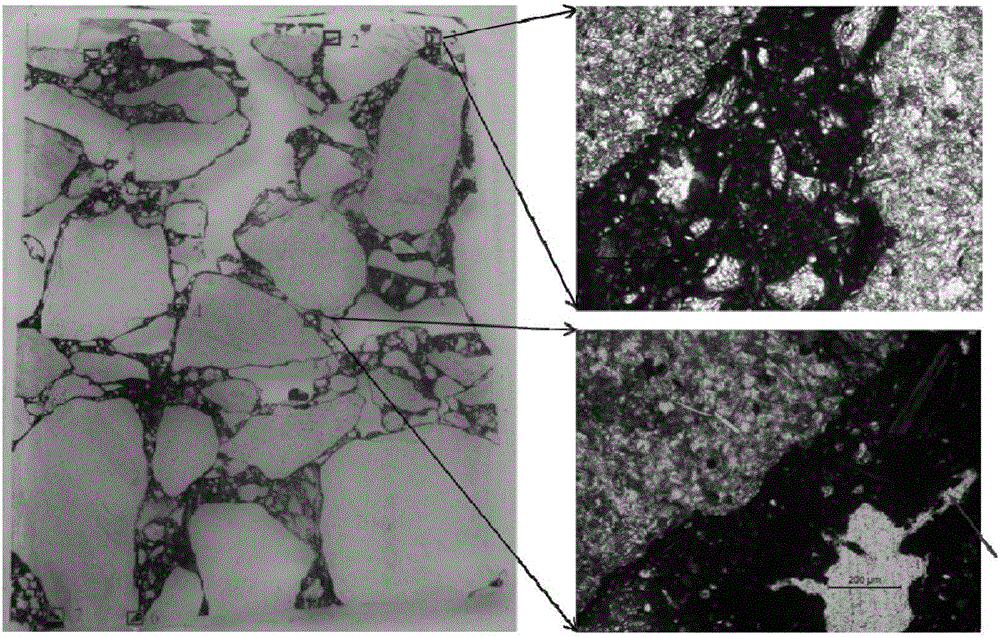

[0031] In this example, the porous asphalt mixture sample has a porosity of 16.2%. The preparation method of the asphalt mixture super flakes includes the following steps:

[0032] 1) Cut the asphalt mixture into samples of asphalt mixture no more than 30mm×40mm×20mm (width×length×thickness), then immerse it in the uncured polyester material, and put 25 The epoxy resin with a viscosity of 2500mPa.s at ℃ is filled into the voids of the asphalt mixture sample, and the asphalt mixture sample filled with polyester material is obtained;

[0033] 2) The low-viscosity epoxy resin in the asphalt mixture sample to be filled with polyester material is cured for 48 hours, then cut into slices with a thickness of 4mm, and then use 9mm emery, 6mm emery, 3mm emery abrasive paste and 0.3 Millimeter emery grinding paste polishes one side of the slice, and uses water as the cooling fluid to obtain a smooth, flat and undamaged surface, and until the thickness deviation of the slice is less than 0.0...

Embodiment 2

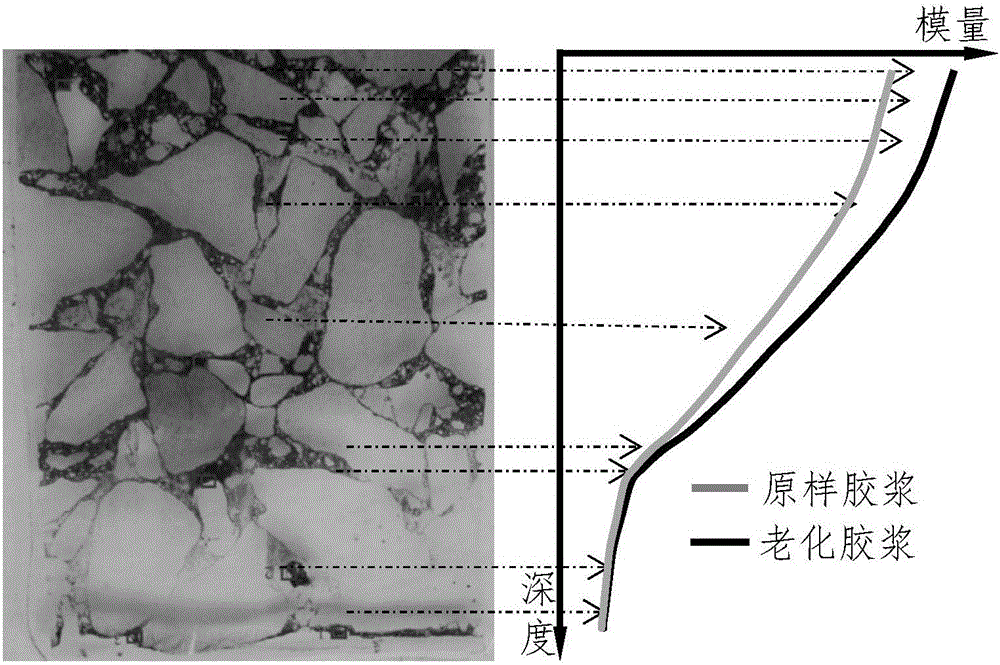

[0037] This embodiment is aimed at the densely-mixed AC13 asphalt mixture sample, and the porosity is 4.6%. By adopting the method of the invention, the asphalt mixture ultra-thin slices with a thickness of only 0.03 mm and which can be used for microscopic analysis are successfully prepared. Aiming at the asphalt mixture super thin slices obtained by the preparation method of the present invention, it can be used for nano-probe modulus analysis, so as to obtain the modulus distribution diagram that changes with the depth of the test piece, such as image 3 Shown. image 3 In the curve on the right side, with the extension of service time, the asphalt mortar close to the surface is affected by external conditions, and the degree of aging is the most significant. Therefore, it shows a modulus distribution diagram like the black curve, that is, the closer to the road surface, the mortar The greater the modulus of the asphalt pavement; when the surface of the asphalt pavement is ...

Embodiment 3

[0039] By adopting the preparation method of the present invention, it is also possible to prepare asphalt mixture super flakes with the asphalt mixture gradation type spuperpave 12.5 and the porosity of 5.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com