Determining method for lead contents in gold concentrate and lead concentrate

A method of determination, the technology of lead concentrate, applied in the determination of lead content in lead concentrate, and the field of gold concentrate, can solve the problems of complex composition methods, insufficient, inapplicable test result accuracy, etc., and achieve simple, convenient and efficient operation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

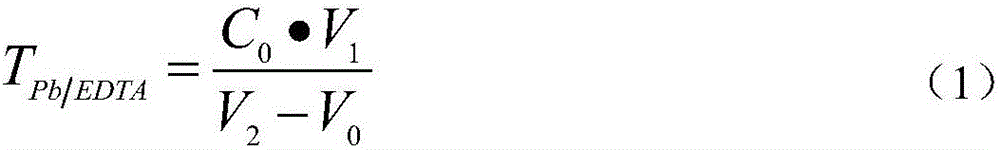

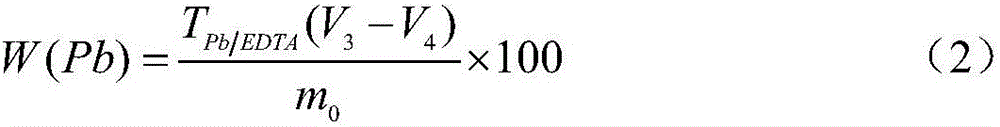

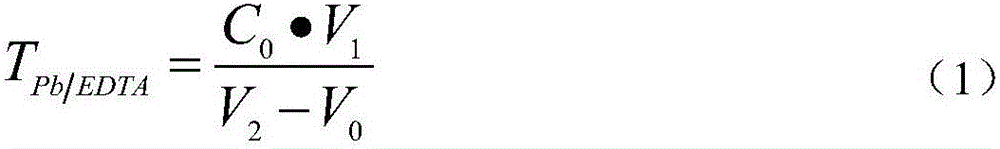

Method used

Image

Examples

Embodiment 1

[0042] Include the following steps:

[0043] (1) Weigh 0.3g of the sample to be tested, accurate to 0.0001g, place it in a 400mL beaker, add 15mL of nitric acid, add 2mL of bromine water dropwise, cover with a watch glass, and heat until the sample to be tested is decomposed;

[0044] (2) After taking off the beaker and cooling it for a while, add 10mL of concentrated sulfuric acid, heat until thick white smoke is emitted, then take off the beaker and cool;

[0045] (3) Add 5mL of water and 10mL of hydrobromic acid, heat until thick white smoke is emitted, cool, add 5mL of dilute sulfuric acid and 10mL of hydrobromic acid, heat again until thick white smoke is emitted, and cool;

[0046] (6) Wash the cup wall and watch glass with water, adjust the volume to 90mL, put it on the electric stove and heat it to boil, and keep boiling for 10min, then take it out and cool it to room temperature;

[0047] (7) Add 10mL of ethanol, and let the lead sulfate precipitate stand for 2h;

...

Embodiment 2

[0051] Include the following steps:

[0052] (1) Weigh 0.4g of the sample to be tested, accurate to 0.0001g, place it in a 400mL beaker, add 20mL of nitric acid, add 3mL of bromine water dropwise, cover with a watch glass, and heat until the sample to be tested is decomposed;

[0053] (2) After taking off the beaker and cooling it for a while, add 12mL of concentrated sulfuric acid, heat until thick white smoke is emitted, then take off the beaker and cool;

[0054] (3) Add 5mL of water and 13mL of hydrobromic acid, heat until thick white smoke is emitted, cool, add 5mL of dilute sulfuric acid and 13mL of hydrobromic acid, heat again until thick white smoke is emitted, and cool;

[0055] (8) Wash the cup wall and watch glass with water, and adjust the volume to 950mL, put it on the electric stove and heat it to boil, and keep boiling for 10 minutes, then take it out and cool it to room temperature;

[0056] (9) Add 10 mL of ethanol, and let the lead sulfate precipitate stand ...

Embodiment 3

[0060] Include the following steps:

[0061] (1) Weigh 0.5g of the sample to be tested, accurate to 0.0001g, place it in a 400mL beaker, add 25mL of nitric acid, add 3mL of bromine water dropwise, cover with a watch glass, and heat until the sample to be tested is decomposed;

[0062] (2) After taking off the beaker and cooling it for a while, add 15mL of concentrated sulfuric acid, heat until thick white smoke is emitted, then take off the beaker and cool;

[0063] (3) Add 5mL of water and 15mL of hydrobromic acid, heat until thick white smoke is emitted, cool, add 5mL of dilute sulfuric acid and 15mL of hydrobromic acid, heat again until thick white smoke is emitted, and cool;

[0064] (10) Wash the cup wall and watch glass with water, adjust the volume to 100mL, put it on the electric stove and heat it to boil, and keep boiling for 10 minutes, then take it out and cool it to room temperature;

[0065] (11) Add 10mL of ethanol, and let the lead sulfate precipitate stand for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com