Flexible copper grid base transparent conducting thin film

A technology of transparent conductive film and copper mesh grid, which is applied to the conductive layer on the insulating carrier and other directions, can solve the problems of difficult to obtain high transmittance and low resistance transparent conductive film, low composite transmittance, etc., and achieve production costs. The effect of low, high transmittance, strong environmental resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

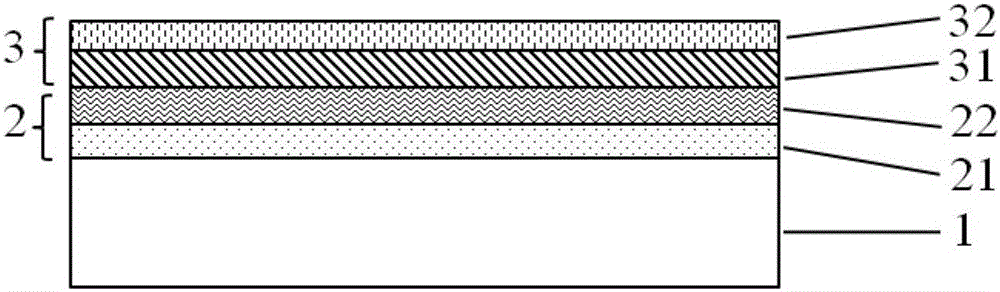

[0027] like figure 1 As shown, this figure shows an embodiment of a flexible copper grid base transparent conductive film, and the composite film includes a flexible transparent polyethylene terephthalate (PET) substrate film 1, which reduces reflection and anti-reflection layer 2 and copper grid conductive layer 3.

[0028] The transparent film substrate 1 is composed of flexible transparent polyethylene terephthalate and its double-sided UV-cured polyacrylate hard coating. Preferably, the thickness of the flexible transparent substrate 1 is 50 microns, and may also be 125 microns. The UV-cured polyacrylate hardening coating is evenly coated on both sides of the flexible transparent PET substrate by a traditional roll-to-roll coating method, so as to improve the strength, hardness and durability of the flexible transparent substrate 1 .

[0029] The anti-reflection and anti-reflection layer 2 is a multi-layer stacked structure, covering the surface layer of the flexible tra...

Embodiment 2

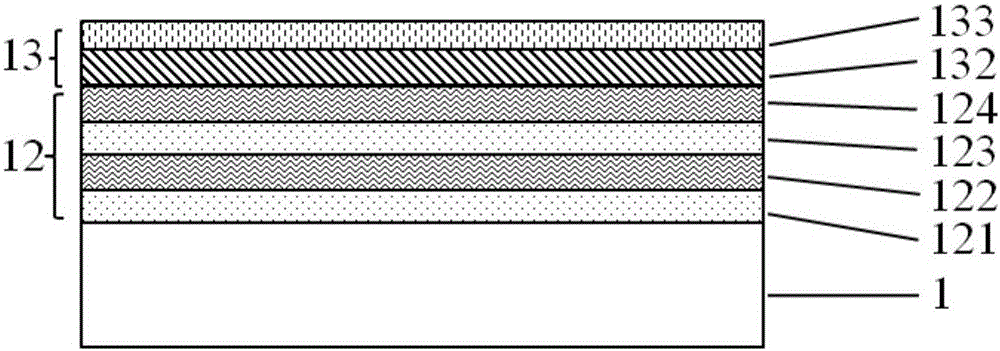

[0032] like figure 2 As shown, this figure shows an embodiment of a flexible copper grid-based transparent conductive film, and the composite film includes a flexible transparent polyethylene terephthalate PET substrate film 1, anti-reflection and anti-reflection layer 12 And copper grid conductive layer 13.

[0033] The transparent film substrate 1 is composed of flexible transparent polyethylene terephthalate and its double-sided UV-cured polyacrylate hard coating. Preferably, the thickness of the flexible transparent substrate 1 is 50 microns, and may also be 125 microns. The UV-cured polyacrylate hardening coating is evenly coated on both sides of the flexible transparent PET substrate by a traditional roll-to-roll coating method, so as to improve the strength, hardness and durability of the flexible transparent substrate 1 .

[0034] The anti-reflection and anti-reflection layer 12 is a multi-layer stacked structure, covering the surface layer of the flexible transpare...

Embodiment 3

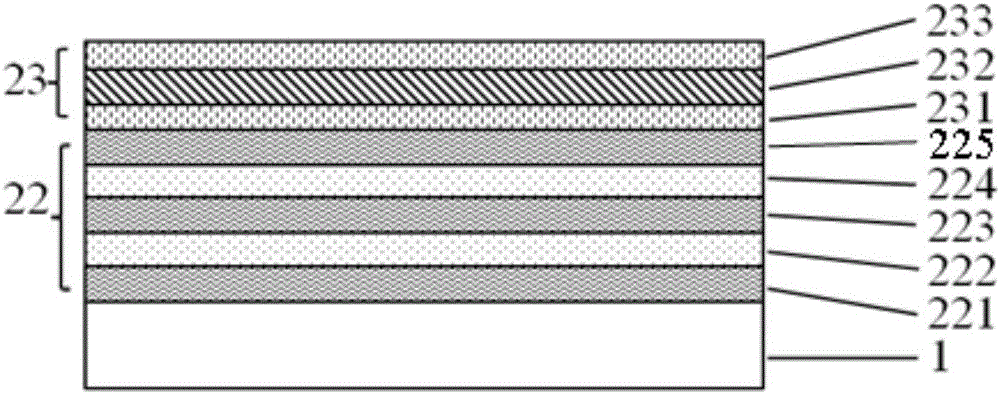

[0038] like image 3 As shown, this figure shows an embodiment of a flexible copper grid-based transparent conductive film, and the composite film includes a flexible transparent polyethylene terephthalate PET substrate film 1, anti-reflection and anti-reflection layer 22 And copper grid conductive layer 23.

[0039] The transparent film substrate 1 is composed of flexible transparent polyethylene terephthalate and its double-sided UV-cured polyacrylate hard coating. Preferably, the thickness of the flexible transparent substrate 1 is 50 microns, and may also be 125 microns. The UV-cured polyacrylate hardening coating is evenly coated on both sides of the flexible transparent PET substrate by a traditional roll-to-roll coating method, so as to improve the strength, hardness and durability of the flexible transparent substrate 1 .

[0040] The anti-reflection and anti-reflection layer 22 is a multi-layer stacked structure, covering the surface layer of the flexible transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com