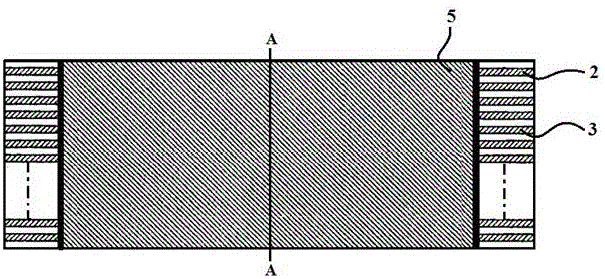

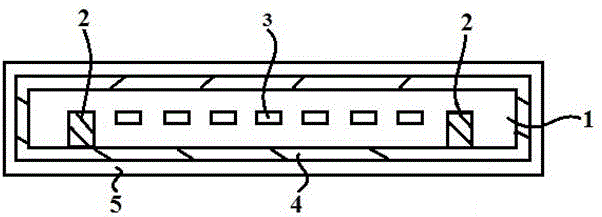

Flat cable used for computer display

A flat cable and display technology, applied in the direction of flat/ribbon cables, insulated cables, communication cables, etc., can solve the problems of interfering wire data transmission, electromagnetic interference, complex operation, etc., to prevent electromagnetic leakage, meet miniaturization, Improve shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, an electrolytic copper foil with a surface roughness of 0.2 μm and a thickness of 10 μm is used for the following surface treatment. The electrolytic copper foil is washed with alkali in an aqueous solution of sodium hydroxide with a concentration of 10 wt%, and then washed with water; Then, the activation treatment is carried out in dilute sulfuric acid with a concentration of 5wt%, and the activation treatment time is 10 minutes. After the pretreatment, the treated copper foil was oxidized in an oxidizing solution consisting of 0.05wt% 2-thiol imidazoline, 0.01wt% benzotriazole, 1.0wt% Tetraethoxysilane, 5.0wt% hydrogen peroxide, 5.0wt% sodium carbonate, and the rest water. The temperature of the oxidation treatment was 60° C., and the treatment time was 15 minutes.

Embodiment 2

[0025]In this embodiment, an electrolytic copper foil with a surface roughness of 0.2 μm and a thickness of 10 μm is used for the following surface treatment. The electrolytic copper foil is washed with alkali in an aqueous solution of sodium hydroxide with a concentration of 10 wt%, and then washed with water; Then, the activation treatment is carried out in dilute sulfuric acid with a concentration of 5wt%, and the activation treatment time is 10 minutes. After the pretreatment, the treated copper foil was oxidized in an oxidative solution consisting of 1.0wt% 2-thiol imidazoline, 0.05wt% benzotriazole, 0.50wt% Tetraethoxysilane, 10.0wt% hydrogen peroxide, 5.0wt% sodium carbonate, and the rest water. The temperature of the oxidation treatment was 40° C., and the treatment time was 10 minutes.

Embodiment 3

[0027] In this embodiment, an electrolytic copper foil with a surface roughness of 0.2 μm and a thickness of 10 μm is used for the following surface treatment. The electrolytic copper foil is washed with alkali in an aqueous solution of sodium hydroxide with a concentration of 10 wt%, and then washed with water; Then, the activation treatment is carried out in dilute sulfuric acid with a concentration of 5wt%, and the activation treatment time is 10 minutes. After the pretreatment, the treated copper foil was oxidized in an oxidative solution consisting of 0.10wt% 2-thiol imidazoline, 0.02wt% benzotriazole, 0.50wt% Tetraethoxysilane, 1.0wt% hydrogen peroxide, 10.0wt% sodium carbonate, and the rest water. The temperature of the oxidation treatment was 50° C., and the treatment time was 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com