Modularized composite crystal preparation system

A compound crystal and preparation system technology, applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of waste, single function, large amount of funds, etc., and achieve the effect of saving equipment cost and laboratory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The modular composite crystal preparation system of the present invention can conveniently replace different crystal growth temperature field modules, realize crystal growth in different methods, and prepare different types of functional crystals.

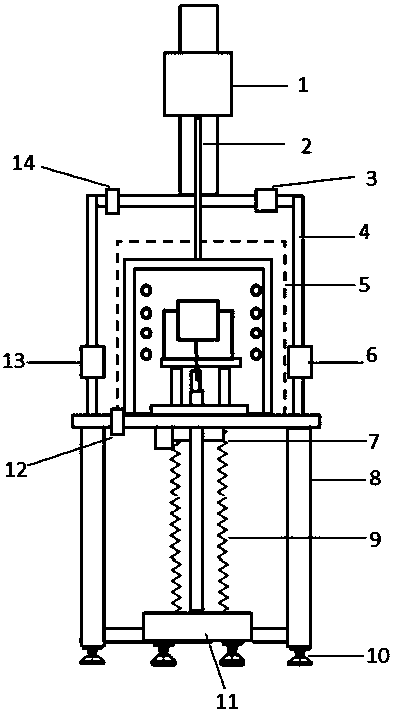

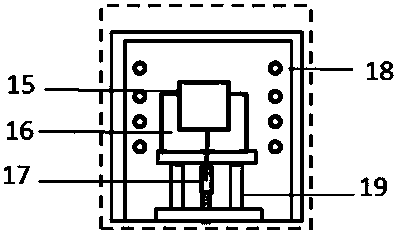

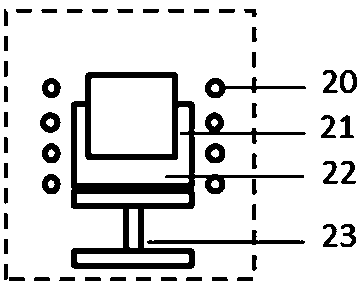

[0026] Such as figure 1 As shown, the modular composite crystal preparation system of the present invention includes a furnace frame 8, a furnace cavity 4, a crystal growth temperature field module 5, a rotating lifting weighing unit 1, a lifting mechanism 7, an independent base 11, and a video image monitoring system 3 and control system. The bottom of the hob 8 is provided with shock-absorbing feet 10, and the verticality of the whole can be adjusted by adjusting the feet 10.

[0027] The furnace chamber 4 is arranged on the furnace rack 8, the furnace chamber 4 is a double-layer stainless steel or transparent quartz glass furnace chamber, and a front door is arranged on one side of the furnace chamber 4, which is used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com