A kind of sodium ion battery metal oxide/polypyrrole hollow nanotube negative electrode composite material and preparation method thereof

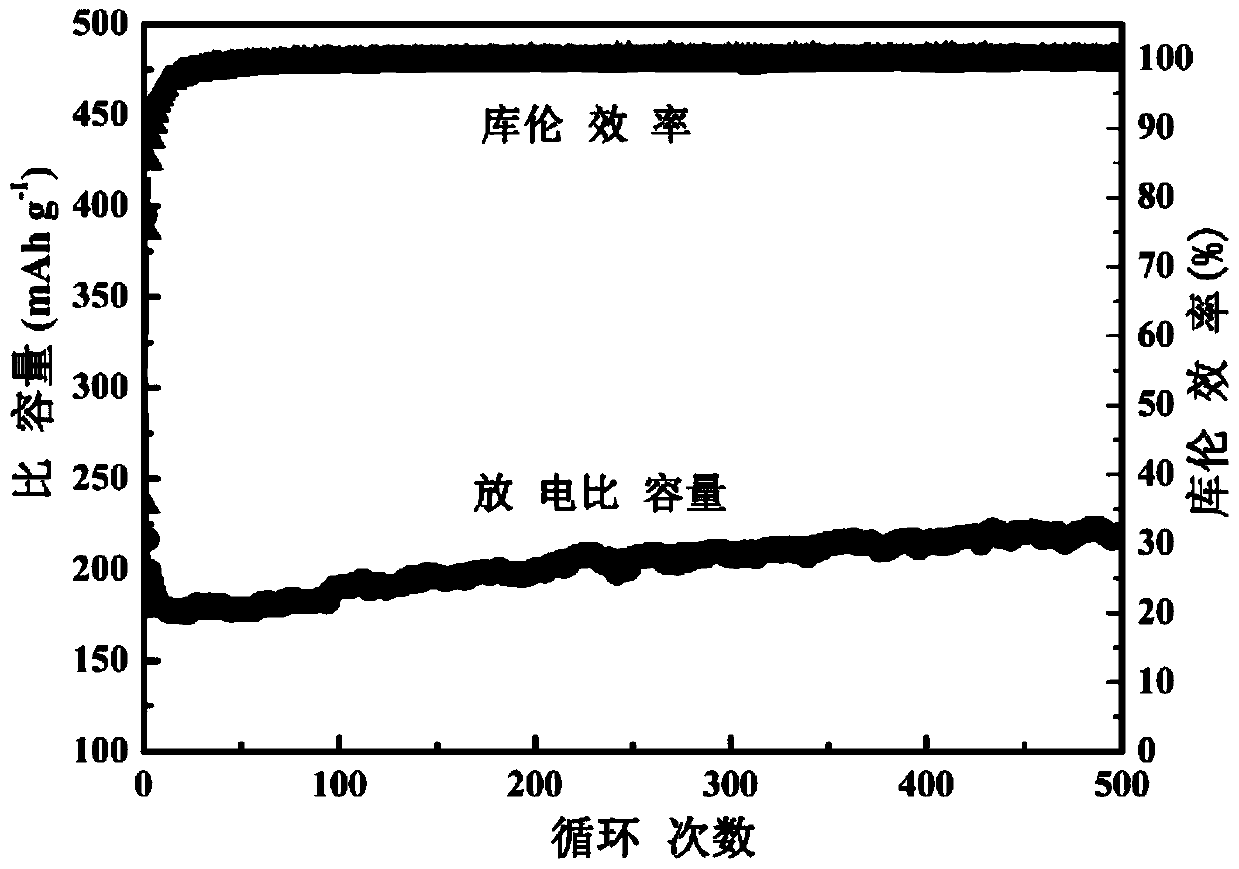

A sodium-ion battery, hollow nanotechnology, applied in the direction of battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of low electronic/ionic conductivity, reduce the rate performance of electrode materials, reduce the cycle stability of electrode materials, etc., to achieve repeatable Good performance, excellent cycle stability, broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First weigh 0.8g of methyl orange to fully dissolve it in deionized water, then weigh 5g of ferric chloride and slowly add it to the above solution under magnetic stirring conditions, and transfer the mixed solution to the water bath after continuous stirring for 2h 0.8 mL of pyrrole monomer was added dropwise to the above mixed solution under the condition of ice bath and kept under magnetic stirring for 24 h, so that the pyrrole monomer was fully polymerized in situ. Finally, the collected precipitate is filtered, washed and dried to obtain the polypyrrole hollow nanotube material.

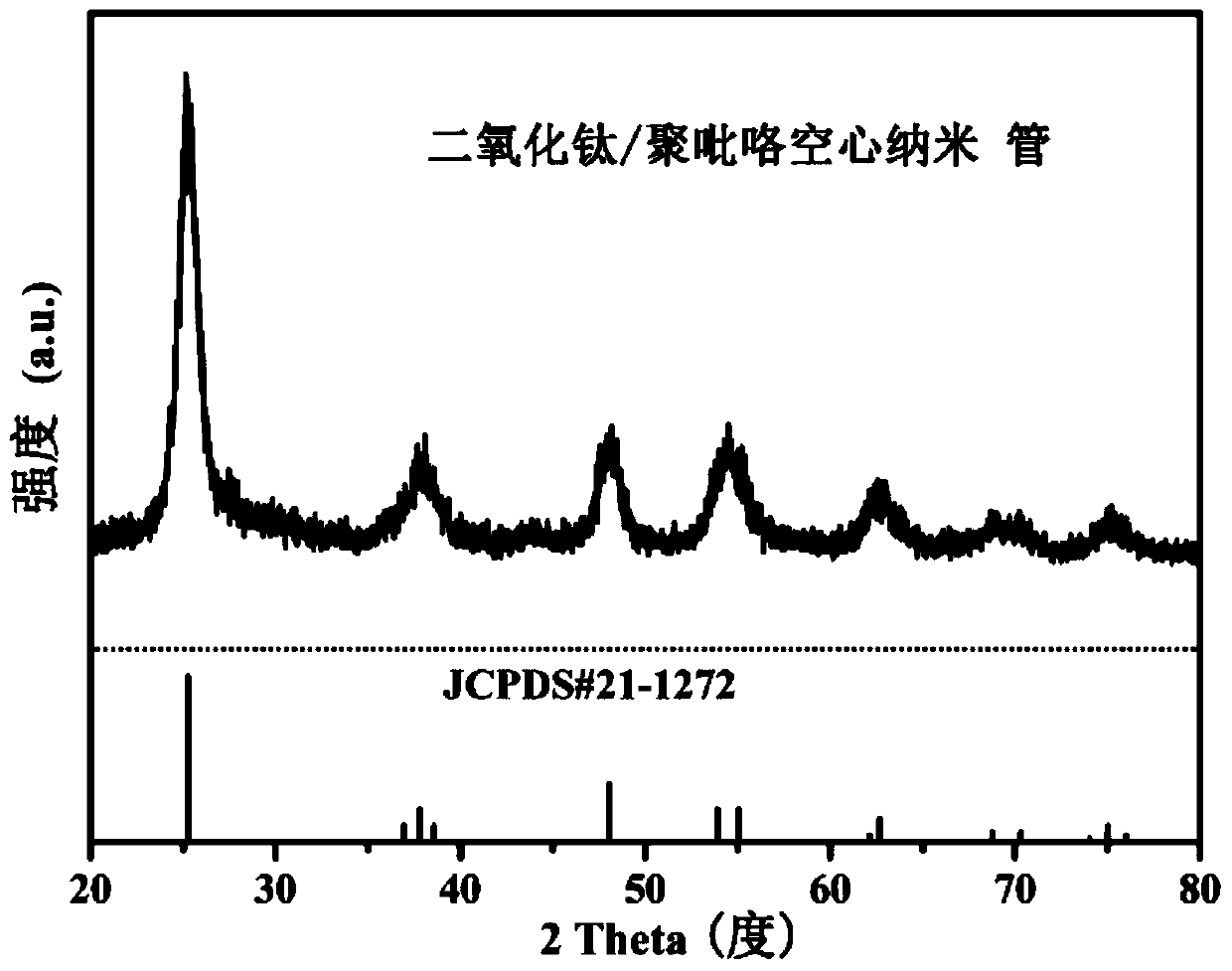

[0039]Weigh 0.06 g of polypyrrole hollow nanotubes and add them into 150 mL of deionized water for ultrasonication for 2 h, then stir for 1 h under magnetic stirring conditions to fully disperse the polypyrrole hollow nanotubes in the deionized aqueous solution. Then 1 g of titanium sulfate was weighed and added to 50 mL of deionized water to fully dissolve it under stirring conditions, a...

Embodiment 2

[0046] First weigh 0.8g of methyl orange to fully dissolve it in deionized water, then weigh 5g of ferric chloride and slowly add it to the above solution under magnetic stirring conditions, and transfer the mixed solution to the water bath after continuous stirring for 2h 0.8 mL of pyrrole monomer was added dropwise to the above mixed solution under the condition of ice bath and kept under magnetic stirring for 24 h, so that the pyrrole monomer was fully polymerized in situ. Finally, the collected precipitate is filtered, washed and dried to obtain the polypyrrole hollow nanotube material.

[0047] Weigh 0.12 g of polypyrrole hollow nanotubes and add them into 150 mL of deionized water for ultrasonication for 2 h, then stir for 1 h under magnetic stirring conditions to fully disperse the polypyrrole hollow nanotubes in the deionized aqueous solution. Then 1 g of titanium sulfate was weighed and added to 50 mL of deionized water to fully dissolve it under stirring conditions, ...

Embodiment 3

[0050] First weigh 0.5g of methyl orange to fully dissolve it in deionized water, then weigh 5g of ferric chloride and slowly add it to the above solution under magnetic stirring conditions, and transfer the mixed solution to the water bath after continuous stirring for 2 hours 0.8 mL of pyrrole monomer was added dropwise to the above mixed solution under the condition of ice bath and kept under magnetic stirring for 24 h, so that the pyrrole monomer was fully polymerized in situ. Finally, the collected precipitate is filtered, washed and dried to obtain the polypyrrole hollow nanotube material.

[0051] Weigh 0.06 g of polypyrrole hollow nanotubes and add them into 150 mL of deionized water for ultrasonication for 2 h, then stir for 1 h under magnetic stirring conditions to fully disperse the polypyrrole hollow nanotubes in the deionized aqueous solution. Then 1 g of titanium sulfate was weighed and added to 50 mL of deionized water to fully dissolve it under stirring conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com