Method for preparing porous tubular negative electrode carbon material of sodium ion battery by taking plant hair as raw material

A sodium-ion battery and carbon material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable electrolyte penetration and complicated preparation process, and achieve complete penetration, simple preparation process, and increase specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) remove the seeds of the loquat hair collected, wash, dry, and seal and preserve;

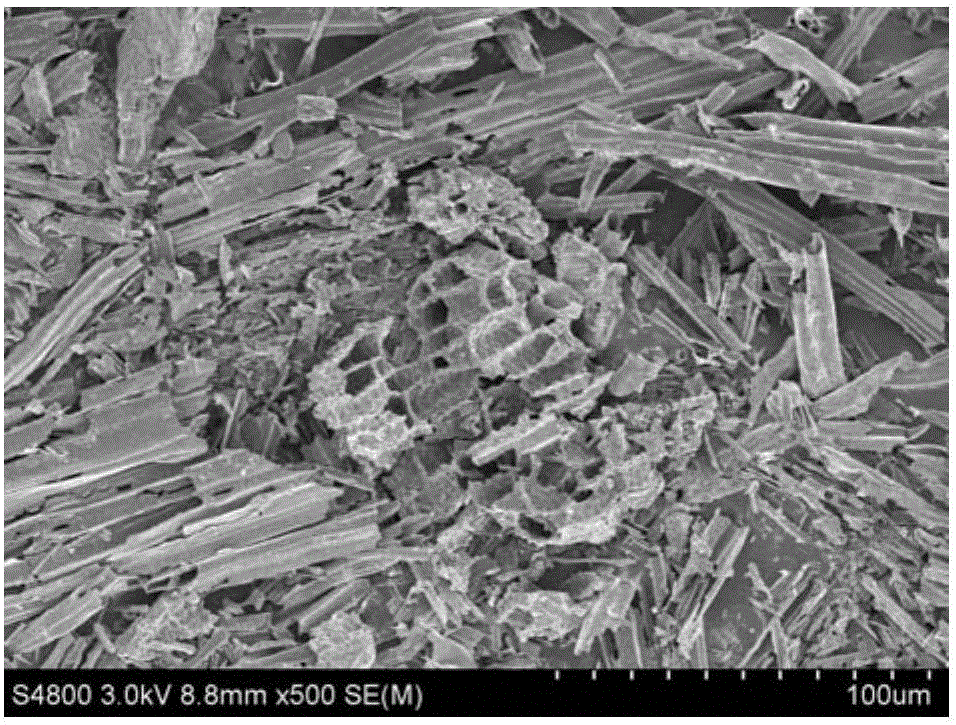

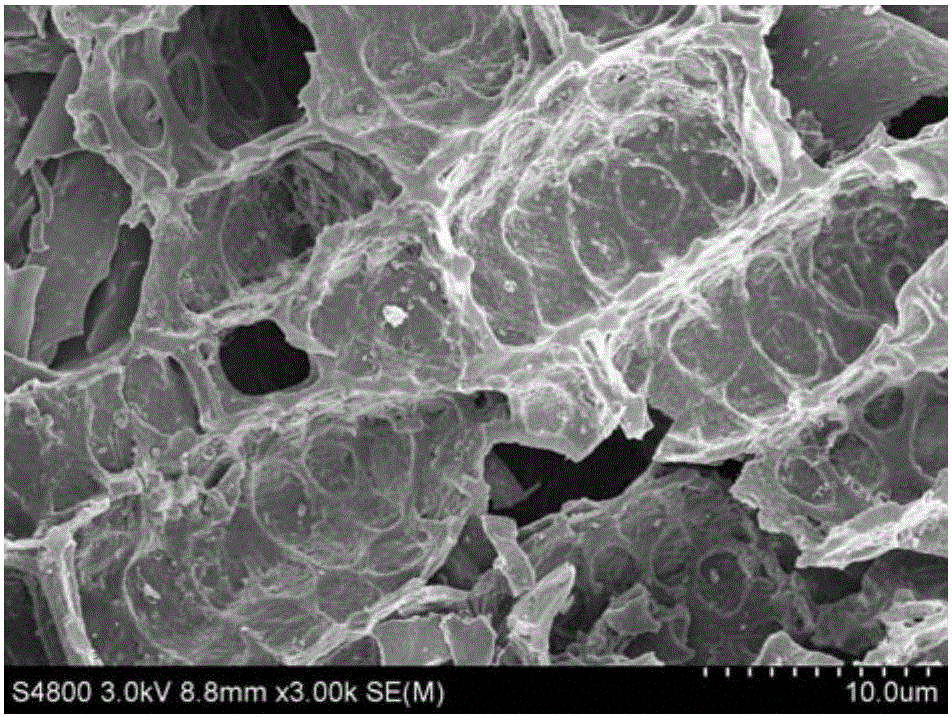

[0031] (2) Weigh 4.0g washed dandelion with a balance, and mix it with NH 4 F is placed in a white porcelain boat with a mass ratio of 1:0.1, placed in a tube furnace under argon protection, and the argon flow rate is 0.2 sccm·min -1 , at a heating rate of 2°C·min -1 Raise the temperature to the calcination temperature of 600°C and keep it warm for 3h.

[0032] (3) The calcined product was washed with 2 mol / L hydrochloric acid and water, and dried to obtain a porous tubular sodium ion battery negative electrode carbon material.

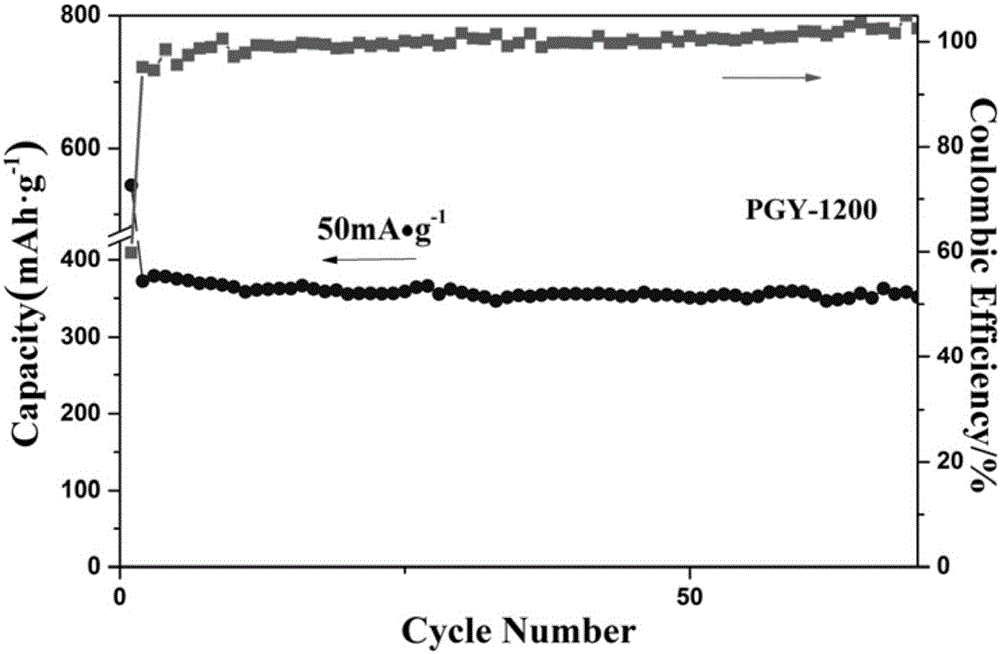

Embodiment 2

[0034] (1) remove the seeds of the collected dandelions, wash them, dry them, and seal them for preservation;

[0035] (2) Weigh 2.0 g of washed dandelion with a balance, and mix it with NH 4 Cl was placed in a white porcelain boat with a mass ratio of 1:0.2, and it was placed in a tube furnace under the protection of argon, and the argon flow rate was 0.1 sccm·min -1 , at a heating rate of 5°C·min -1 Raise the temperature to the calcination temperature of 1200°C and keep it warm for 5h.

[0036] (3) The calcined product was washed with 2 mol / L hydrochloric acid and water, and dried to obtain a porous tubular sodium ion battery negative electrode carbon material.

Embodiment 3

[0038] (1) remove the seeds from the collected chrysanthemum hairs, wash, dry, and seal them for preservation;

[0039] (2) Weigh 2.0 g of washed dandelion with a balance, and mix it with NH 4 F is placed in a white porcelain boat with a mass ratio of 1:0.3, placed in a tube furnace under argon protection, and the argon flow rate is 0.2 sccm·min -1 , at a heating rate of 2°C·min -1 Raise the temperature to the calcination temperature of 900°C and keep it warm for 4h.

[0040] (3) The calcined product was washed with 2 mol / L hydrochloric acid and water, and dried to obtain a porous tubular sodium ion battery negative electrode carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com