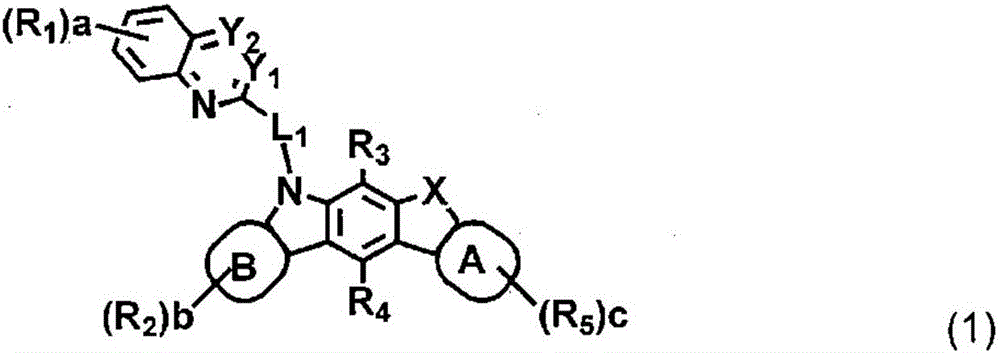

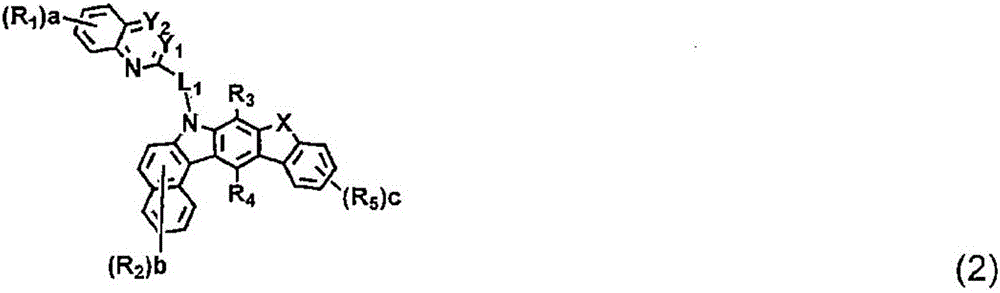

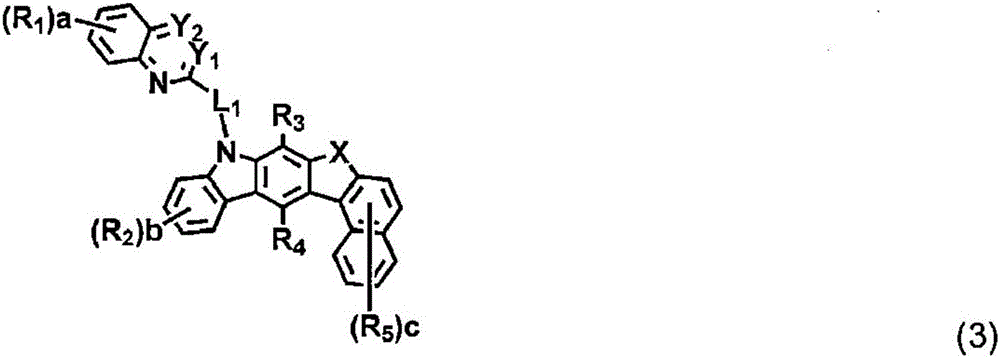

Novel organic electroluminescent compounds and organic electroluminescent device comprising the same

An electroluminescent device and compound technology, applied in electroluminescent light sources, organic chemistry, electric light sources, etc., can solve the problems of low glass transition temperature, decomposition, no advantages, etc., and achieve high luminous efficiency and excellent service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0103] Example 1: Preparation of Compounds H-61, H-60, H-10 and H-11

[0104]

[0105] 1) Preparation of Compound 1-1

[0106] Compound A (100.0 g, 356.0 mmol), 1-naphthylboronic acid (51.0 g, 297.0 mmol), tetrakis(triphenylphosphine) palladium(0) (Pd(PPh 3 ) 4 ) (11.0g, 9.0mmol), 2M K 2 CO 3 (500.0 mL), toluene (1000.0 mL) and ethanol (500.0 mL) for 5 hours. After completing the reaction, extract with ethyl acetate (EA) and pass through with MgSO 4 The organic layer was dried by removing residual moisture. The residue was separated by column chromatography to obtain Compound 1-1 (70.0 g, 72%).

[0107] 2) Preparation of compound 1-2

[0108] Compound 1-1 (70.0 g, 213.0 mmol), triphenylphosphine (140.0 g, 533.0 mmol) and dichlorobenzene (1.0 L) were dissolved in a flask, and the mixture was refluxed at 150° C. for 6 hours. After completing the reaction, the mixture was distilled and triturated with methanol (MeOH) to obtain compound 1-2 (40.0 g, 64%).

[0109...

example 2

[0135] Fabrication of OLED devices using organic electroluminescent compounds according to the invention

[0136] An OLED device was fabricated in the same manner as in Device Example 1 except that Compound H-60 was used as a host in the light emitting material.

[0137] The fabricated OLED device exhibited a brightness of 1050 cd / m at 3.4V 2 red light and a current density of 8.2mA / cm 2 . Furthermore, the time taken for the brightness at 5,000 nits to drop to 90% of the brightness is at least 130 hours.

example 3

[0139] Fabrication of OLED devices using organic electroluminescent compounds according to the invention

[0140] An OLED device was fabricated in the same manner as in Device Example 1 except that Compound H-10 was used as a host and Compound D-88 was used as a dopant in the light emitting material.

[0141] The fabricated OLED device exhibited a brightness of 920cd / m at 3.6V 2 red light and a current density of 12.2mA / cm 2 . Furthermore, the time taken for the brightness at 5,000 nits to drop to 90% of the brightness is at least 110 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com