Manufacturing technology of pastry

A technology for making crafts and pastries, applied in the fields of food science, the function of food ingredients, and the forming of food, can solve the problem that the effect of color, aroma and taste cannot meet the requirements of people's expectations, and the pastry cannot be promoted without balanced nutritional ingredients. and other problems, to achieve the effect of enriching dietary life, ensuring product appearance, and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

[0014] The invention provides a kind of pastry making technology, is used for ice skin making, and this technology comprises the following steps:

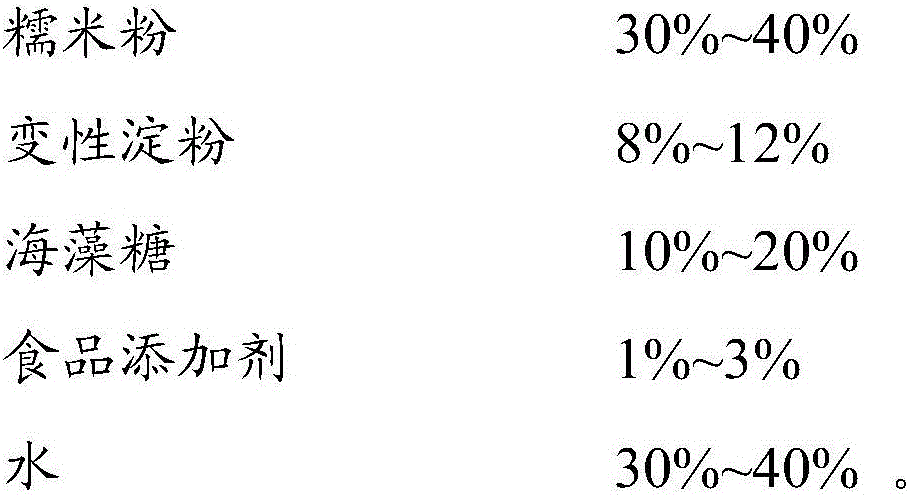

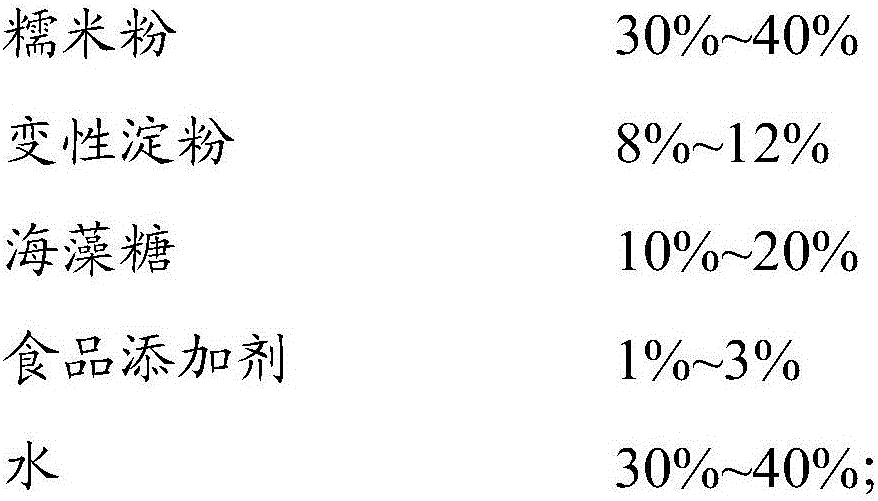

[0015] (1) Mixing materials, mix the sieved glutinous rice flour, modified starch, trehalose, food additives, and water to form the primary mixture. When sieving, put the glutinous rice flour and modified starch into the powder sieving machine Sieve, and the percentage of each component of primary mixing is as follows:

[0016]

[0017] (2), feed feeding, the mixed material of step (1) is added in the steamer, carry out stirring cooking, the pressure inside the steamer is 0.03~0.04mpa, and the cooking time is 17~18min;

[0018] (3) For secondary mixing, maltose syrup and shortening are added to the steamer, and the steamer is started to fully stir the maltose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com