Ultra-short fiber self-foaming baby wipe and producing method thereof

A technology of ultra-short fiber and production method, which is applied in the field of sanitary products, which can solve the problems of insufficient cleaning and sterilization effects, many natural ingredients, and poor comfort, and achieve good cleaning and moistening, good effect, and better comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

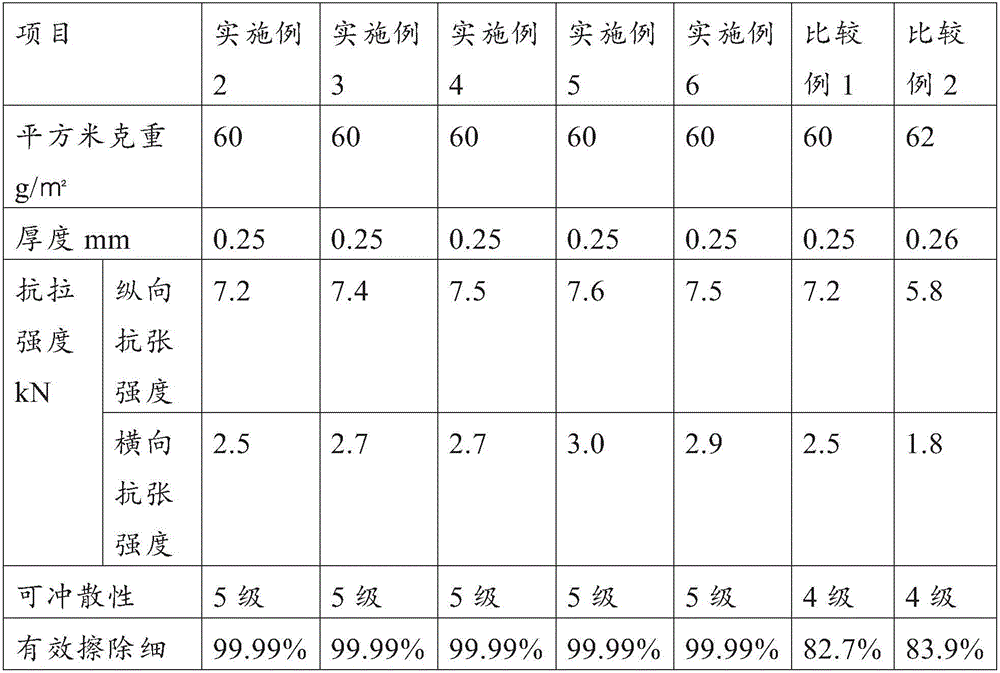

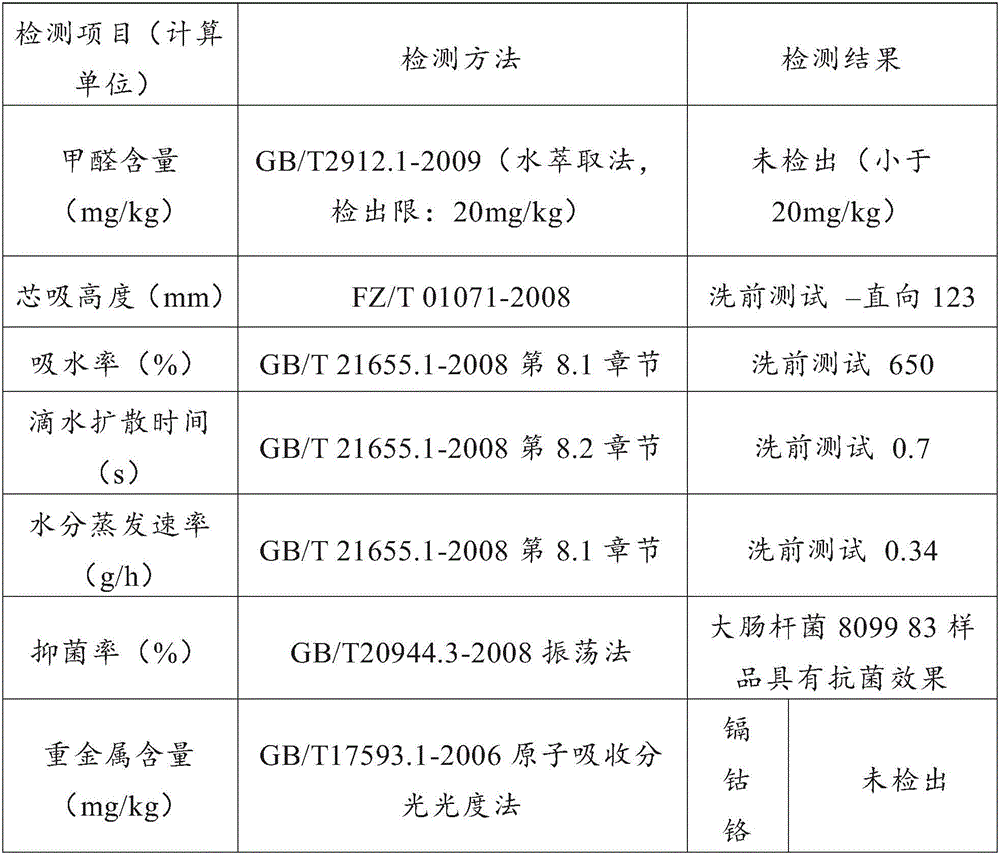

Examples

Embodiment 1

[0029] Embodiment 1: a self-foaming cleaning towel of ultra-short fiber baby, comprising the following raw material components in parts by weight: 1 part of lint, 40 parts of cotton shell, 0.1 part of coconut oil, 10 parts of corn oil.

Embodiment 2

[0030] Embodiment two: a kind of production method of ultra-short fiber baby self-foaming cleaning towel, comprises the following steps:

[0031] Step 1: Pretreatment of lint: dehydrating and removing impurities from the lint to obtain pretreated lint;

[0032] Step 2: Prepare ultra-short fibers: take 1 part by weight of the lint pretreated in step 1 and 40 parts by weight of cotton husks, mix them uniformly, place them in a drum machine for heating and rotating treatment, and obtain ultra-short fibers;

[0033] Step 3: Prepare coconut oil: take coconut fruit, remove the coconut shell, shell and seed coat, wash and cut into pieces, squeeze the juice to obtain coconut milk, add an enzymatic hydrolysis agent to the coconut milk for enzymolysis treatment to obtain enzymolysis Liquid, the enzymolysis solution is added in the centrifuge and carried out centrifugation to obtain crude coconut oil, after filtering through filter cloth, evaporating, leaving standstill treatment, obtain...

Embodiment 3

[0035] Embodiment three: a kind of ultra-short fiber baby self-foaming cleaning towel, comprises the raw material component of following parts by weight: 10 parts of lint cotton, 30 parts of cotton shells, 2 parts of coconut oil, 8 parts of corn oil, 5 parts of Natural extracts, 10 parts of vitamin E, 0.5 parts of geranium essential oil and 10 parts of glycerin. A kind of production method of ultra-short fiber baby self-foaming cleaning towel, comprises the following steps:

[0036] Step 1: Pretreatment of lint: dehydrating and removing impurities from the lint to obtain pretreated lint;

[0037]Step 2: Prepare ultra-short fibers: take 10 parts by weight of the lint pretreated in step 1 and 30 parts by weight of cotton husks, mix evenly, place them in a drum machine for heating and rotating treatment, and obtain ultra-short fibers;

[0038] Step 3: Prepare coconut oil: take coconut fruit, remove the coconut shell, shell and seed coat, wash and cut into pieces, squeeze the jui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com