Preparation method of emulsion for low-solid-content high-quality interior wall latex paint

A high-quality technology for interior wall latex paint, applied in the field of latex paint, can solve the problem of high cost, achieve moderate price, improve user experience, and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

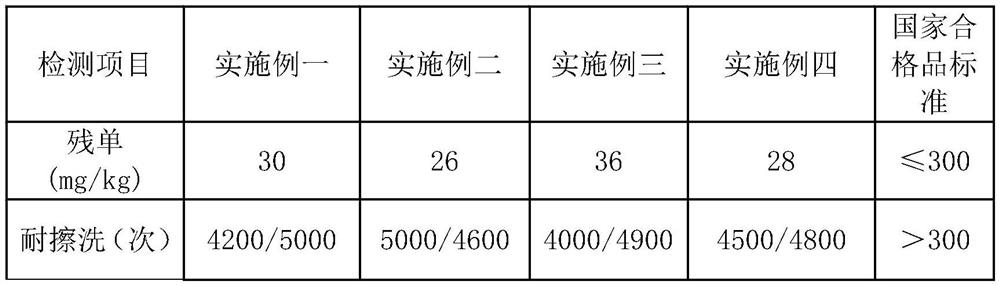

Examples

Embodiment 1

[0021] S1: Add 20 parts of deionized water, 0.5 parts of emulsifier, and 0.1 part of sodium bicarbonate into the reaction bottle device, start stirring, and start to raise the temperature to 86°C.

[0022] S2: Preparation of emulsion: follow the order of 12 parts of water, 1.5 parts of emulsifier, 0.4 parts of completely dissolved sodium bicarbonate, 2 parts of acrylamide, 1 part of acrylic acid, 10 parts of butyl acrylate, 50 parts of styrene, and rinse water Add to the emulsification tank for emulsification.

[0023] S3: Preparation of the first initiator and the second initiator: the first initiator is prepared by adding 0.05 parts of sodium persulfate and 1 part of water into the oxidation bottle, and the second initiator is prepared by adding 5 parts of water and persulfuric acid into the oxidation bottle Prepared with 0.15 parts of sodium.

[0024] S4: When the temperature of the reactor rises to 86°C, add the first initiator. After the temperature is stable, add the em...

Embodiment 2

[0028] S1: Add 35 parts of deionized water, 1.5 parts of emulsifier, and 1 part of sodium bicarbonate into the reaction bottle device, start stirring, and start to heat up to 86°C.

[0029] S2: Preparation of emulsion: follow the order of 15 parts of water, 3.5 parts of emulsifier, 1.5 parts of completely dissolved sodium bicarbonate, 8 parts of acrylamide, 5 parts of acrylic acid, 20 parts of butyl acrylate, 30 parts of styrene, and rinse water Add to the emulsification tank for emulsification.

[0030] S3: Preparation of the first initiator and the second initiator: the first initiator is prepared by adding 0.2 parts of sodium persulfate and 1 part of water into the oxidation bottle, and the second initiator is prepared by adding 7 parts of water into the oxidation bottle Parts, 0.4 parts of sodium persulfate prepared.

[0031] S4: When the temperature of the reactor rises to 86°C, add the first initiator. After the temperature is stable, add the emulsion and the second ini...

Embodiment 3

[0035] S1: Add 25 parts of deionized water, 1 part of emulsifier, and 0.5 parts of sodium bicarbonate into the reaction bottle device, start stirring, and start to heat up to 86 °C.

[0036] S2: Preparation of emulsion: follow the order of 15 parts of water, 2 parts of emulsifier, 1 part of completely dissolved sodium bicarbonate, 6 parts of acrylamide, 4 parts of acrylic acid, 15 parts of butyl acrylate, 40 parts of styrene, and rinse water Add to the emulsification tank for emulsification.

[0037] S3: Preparation of the first initiator and the second initiator: the first initiator is prepared by adding 0.1 parts of sodium persulfate and 1 part of water into the oxidation bottle, and the second initiator is prepared by adding 7 parts of water and persulfuric acid into the oxidation bottle Prepared with 0.3 parts of sodium.

[0038] S4: When the temperature of the reactor rises to 86°C, add the first initiator. After the temperature is stable, add the emulsion and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com