Glass fiber and carbon fiber hybrid composite bicycle middle tube and preparation method thereof

A technology of glass fiber and composite materials, applied in bicycle frames, bicycle accessories, transportation and packaging, etc., can solve the problems of inability to obtain technical and economic benefits, reduce strain capacity, and small adaptability, and achieve improved riding comfort and impact Excellent absorption performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

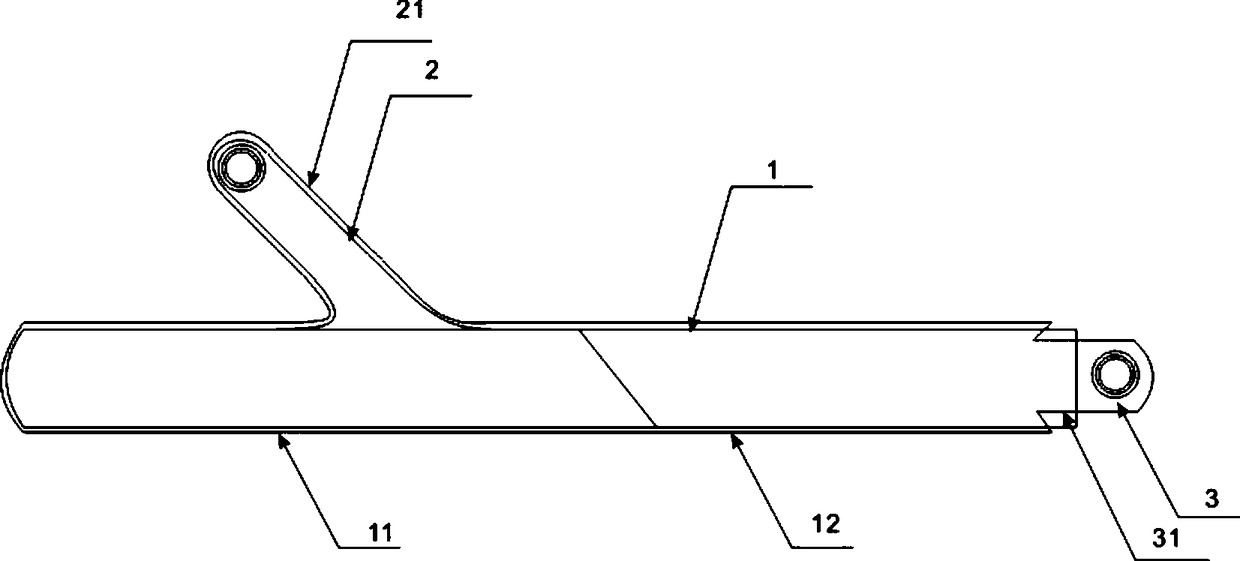

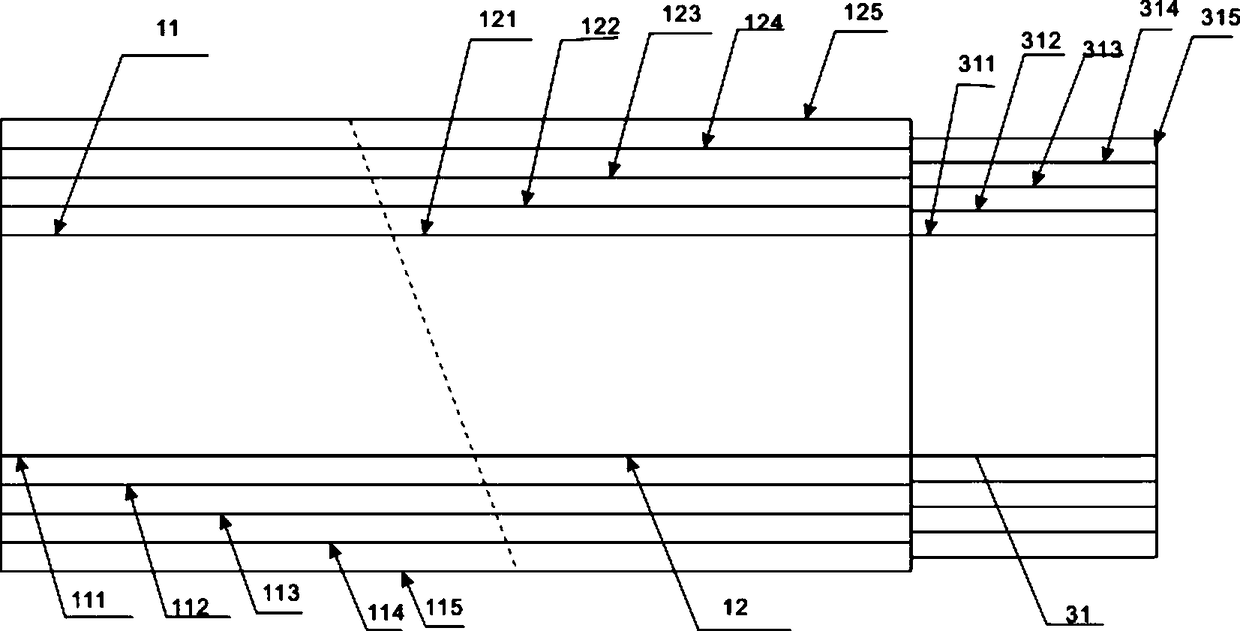

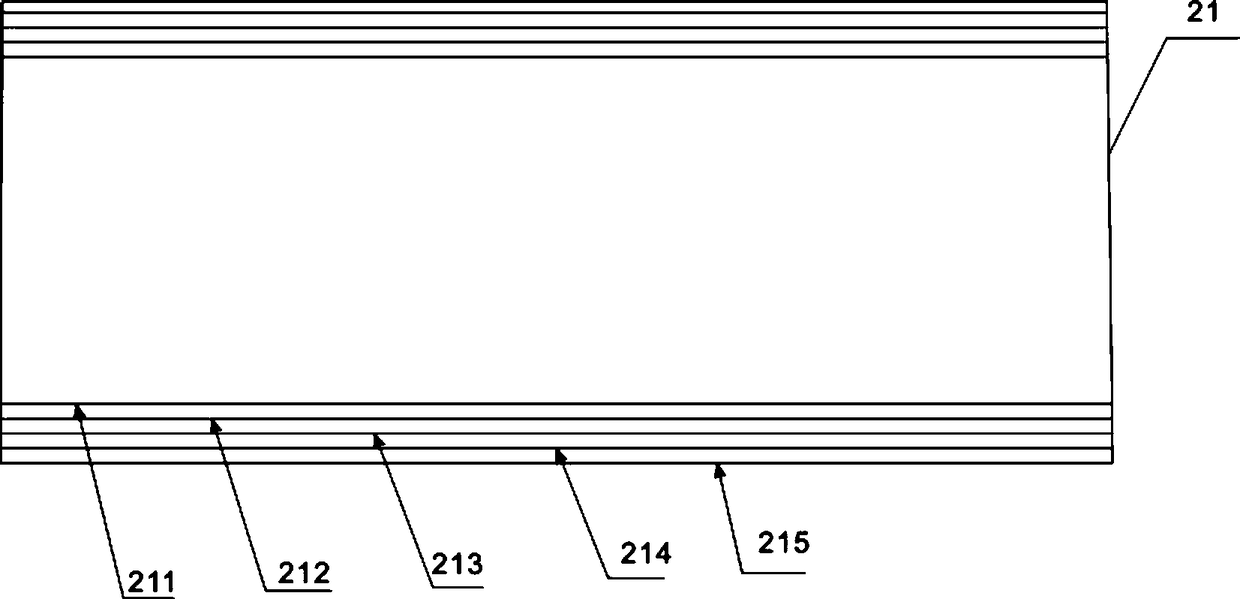

[0041] see figure 1 , the present invention provides a glass fiber and carbon fiber hybrid composite bicycle middle tube, including a vertical long tube 1, a branch tube 2 located in the middle of the vertical long tube and a vertical middle tube tail for connecting the frame bottom bracket The connection part 3. The branch pipe 2, the connection part 3 and the vertical long pipe 1 are integrally formed, and the angle between the branch pipe 2 and the vertical long pipe 1 is 30°-60°. Composite materials include high tenacity 0 degree glass fiber, high tenacity + / -45 degree glass fiber, 0 degree carbon fiber and + / -45 degree carbon fiber.

[0042] Compared with the prior art, the present invention designs a bicycle center tube made of glass fiber and carbon fiber hybrid composite material. According to the force ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com