Preparation method of multi-tip array for large-area micromachining with flatness self-compensation

A large-area, self-compensating technology, applied in the field of preparation of multi-tip arrays, can solve the problems that the flatness of multi-tip arrays is difficult to guarantee, the length of microneedles is limited by laser defocus, and the degree of volume shrinkage is difficult, and it is easy to implement , easy to buy, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Figure 1-6 It shows that a specific embodiment of the present invention is a method for preparing a multi-tip array for large-area micromachining with flatness self-compensation, and its specific method is:

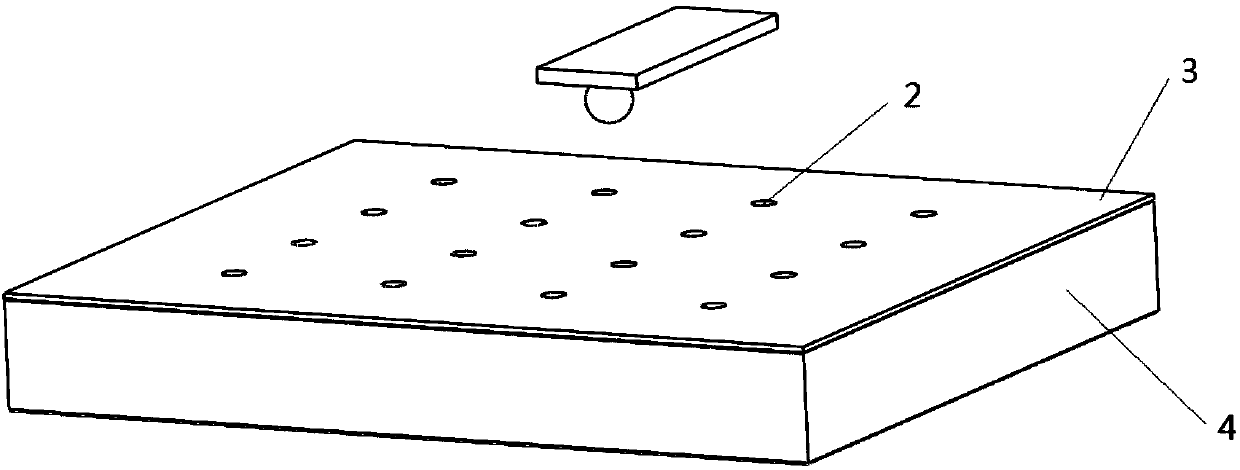

[0027] A. Coat a layer of wax film 3 on the slide glass 4, use multi-probe processing equipment to uniformly dot the wax film 3 and penetrate the wax film 3 to form evenly arranged spots on the wax film 3 Circular groove 2; see figure 1 .

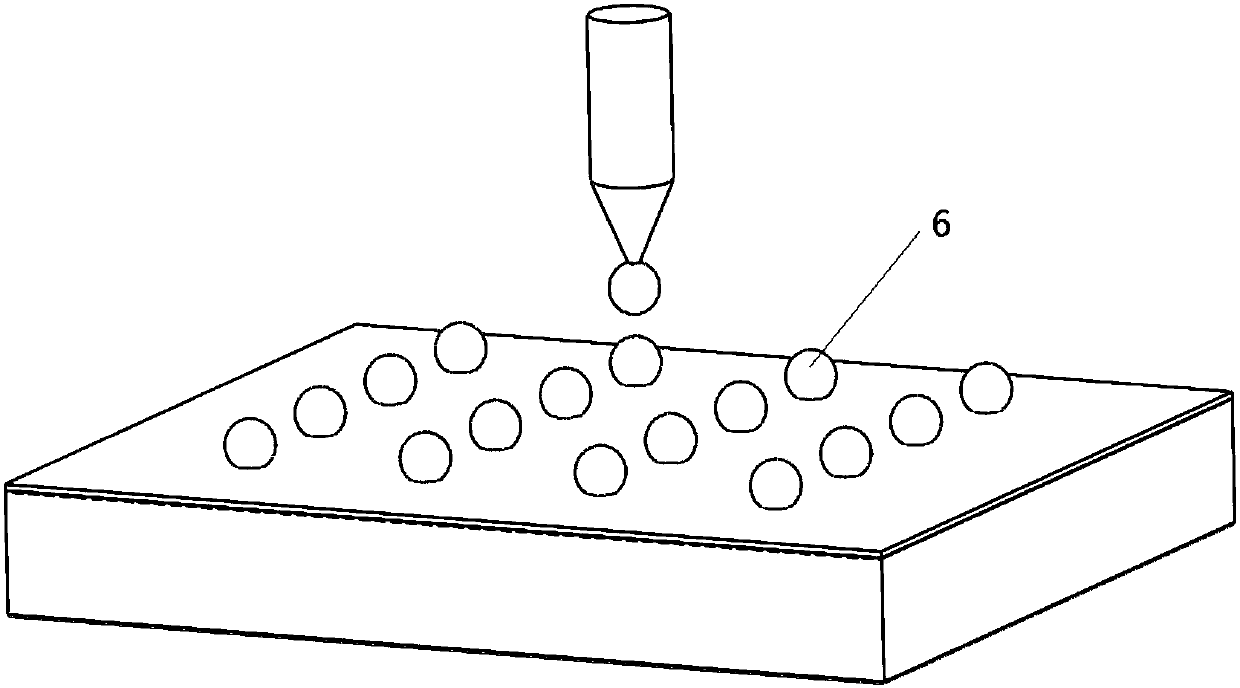

[0028] B, the same microsphere 6 of particle diameter is placed in each groove 2 on the wax film 3 one by one, and the diameter of described microsphere 6 is 5-10 times of the thickness of wax film 3; See figure 2 .

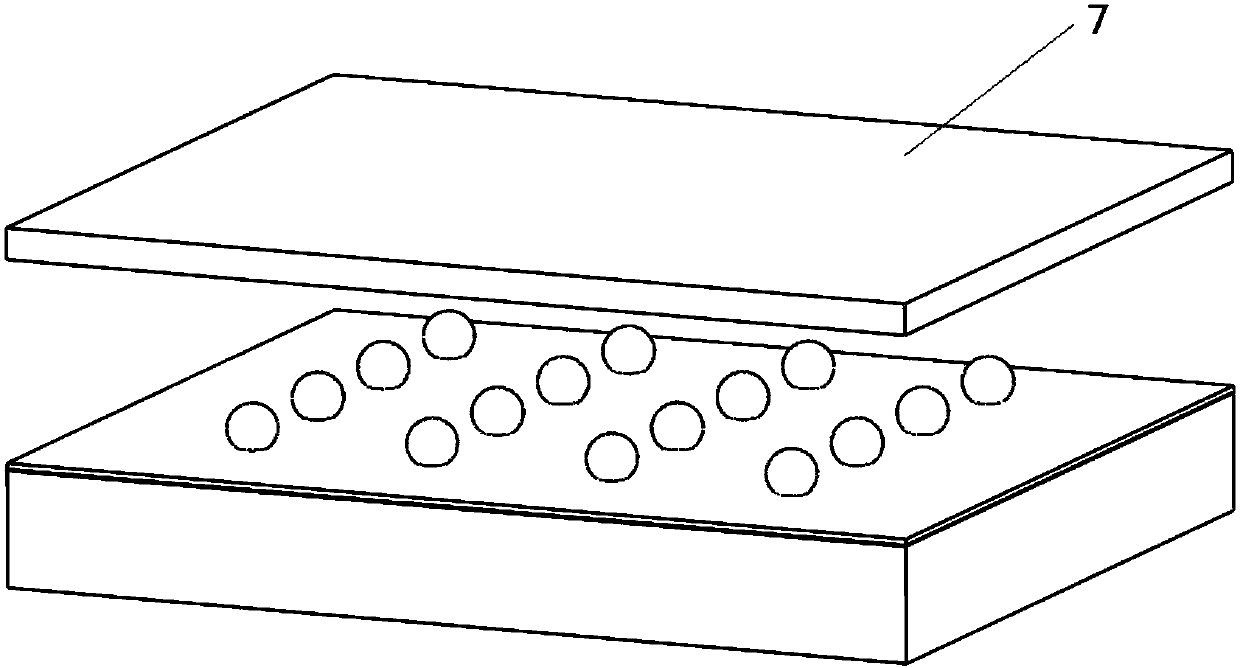

[0029] C. Press the microspheres 6 into the wax film 3 evenly with the glass slide 7, so that all the microspheres 6 are in contact with the slide glass 3; see image 3 .

[0030] D, the elastic material sheet 10 is bonded on the smooth pinpoint plate 8 by K-630 special fast-curing glue 9, and then coated wi...

Embodiment 2

[0035] The operation of this example is basically the same as that of Example 1, except that the microspheres are diamond microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com