Industrial water feeding treatment system

A treatment system and industrial water supply technology, applied in the field of water treatment, can solve the problems of low efficiency of the pretreatment system, frequent ion exchange regeneration, serious environmental pollution, etc., to improve the flocculation effect, avoid alum flower leakage, and evenly distribute the flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

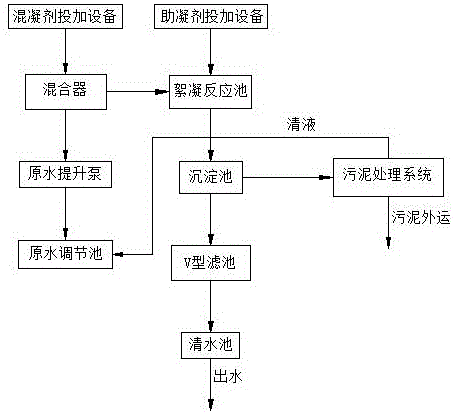

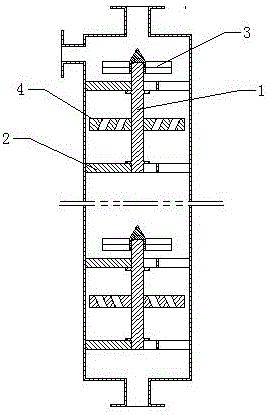

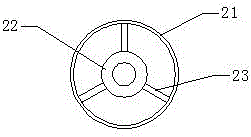

[0019] Such as figure 1 As shown, an industrial water supply treatment system includes a raw water regulating tank, a mixer, a flocculation reaction tank, a sedimentation tank, a sludge tank, a V-shaped filter and a clean water tank. The raw water from outside the factory enters the raw water regulating tank and is regulated by the raw water The pump is lifted to the mixer, fully mixed with the coagulant added by the coagulant dosing equipment in the mixer, and then enters the flocculation reaction tank, and the coagulant aid is added to the flocculation reaction tank. The flocculation reaction tank reacts with suspended solids in the water to quickly form dense and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com