High-permeability concrete sealing waterproofing agent and preparation method thereof

A technology of high-permeability and waterproofing agent, which is applied in the field of high-permeability concrete sealing and waterproofing agent and its preparation, can solve the problems of increased concrete water demand, large amount of common expansion agent, plastic shrinkage cracks, etc., to achieve enhanced waterproofing Corrosion ability, reduction of infiltration channel, effect of reduction of volume deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

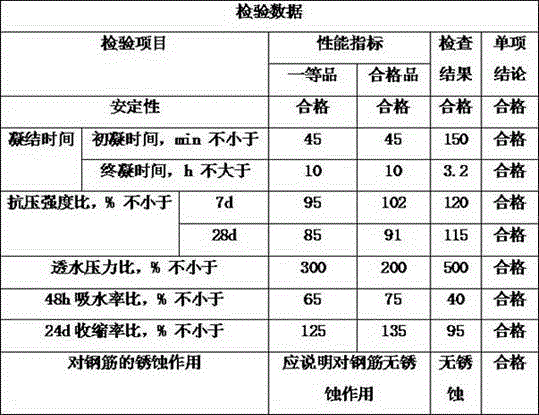

Examples

Embodiment 1

[0021] A kind of highly permeable concrete sealing and waterproofing agent, by weight, is made of the raw materials of the following components: 6 parts of epoxy resin, 3 parts of polyamide, 0.9 part of polyoxyethylene fatty alcohol ether, cetyl trimethoxy 1.2 parts of base silane, 0.5 parts of methyltrihydroxysilane, 1.8 parts of polypropylene fiber, 3 parts of water reducing agent, 3 parts of triethanolamine, 1.1 parts of sodium abietate, 1.0 parts of sodium alkylsulfonate, 48 parts of deionized water, Among them, the water reducer is made of polycarboxylate water reducer and naphthalene water reducer in a weight ratio of 2:3.

Embodiment 2

[0023] A high-permeability concrete sealing and waterproofing agent, made of the following components by weight: 8 parts of epoxy resin, 3 parts of polyamide, 1.0 part of polyoxyethylene fatty alcohol ether, cetyl trimethoxy 1.4 parts of base silane, 0.7 parts of methyltrihydroxysilane, 2.4 parts of polypropylene fiber, 4 parts of water reducing agent, 4 parts of triethanolamine, 1.5 parts of sodium abietate, 1.2 parts of sodium alkylsulfonate, 55 parts of deionized water, Among them, the water reducer is made of polycarboxylate water reducer and naphthalene water reducer in a weight ratio of 1:1.

Embodiment 3

[0025] A highly permeable concrete sealing and waterproofing agent, made of the following components by weight: 7 parts of epoxy resin, 3 parts of polyamide, 0.9 part of polyoxyethylene fatty alcohol ether, cetyl trimethoxy 1.2 parts of base silane, 0.6 parts of methyltrihydroxysilane, 2.2 parts of polypropylene fiber, 4 parts of water reducer, 4 parts of triethanolamine, 1.2 parts of sodium abietate, 1.0 part of sodium alkylsulfonate, 50 parts of deionized water, Among them, the water reducer is made of polycarboxylate water reducer and naphthalene series water reducer at a weight ratio of 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com