A manufacturing method of hot-extruded polyethylene zinc-aluminum alloy coated steel wire cable

A technology of zinc-aluminum alloy and production method, which is applied in the field of bridge cables to achieve a reliable mechanical seal structure and overcome the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

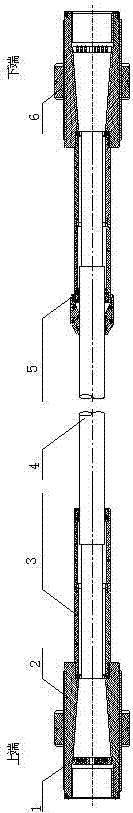

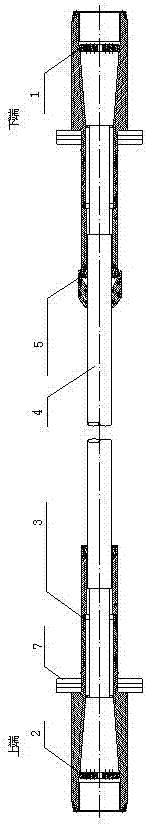

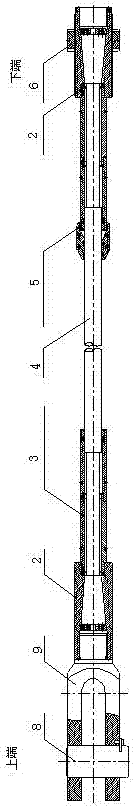

[0085] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0086] The cable involved in this embodiment is twisted together with zinc-aluminum alloy-coated steel wires to form a cable body, and then hot-extruded a polyethylene protective layer on the outer layer of the cable body, and anchors are poured at both ends, and then coiled and transported to the erection site. Build root by root.

[0087] Specific implementation steps:

[0088] (1) Making zinc-aluminum alloy coated steel wire

[0089] The steel wire used in this embodiment adopts zinc-aluminum alloy coated steel wire, which has higher corrosion resistance than pure zinc coating. 9.2%~12.2%, coating weight not less than 300g / m 2 .

[0090] (2) Making standard length steel wire

[0091] Because there is a certain twist angle in each layer of steel wires of the cable stay, only the center wire does not twist during the whole production pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com