Flexible silicon-based nanometer thin film thermoelectric device

A nano-thin film and thermoelectric device technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device junction lead-out materials, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problem of not being able to adapt to high-temperature annealing and difficult to silicon-based devices Integration, high cost and other issues, achieve the effect of reducing internal stress, good thermal conductivity, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

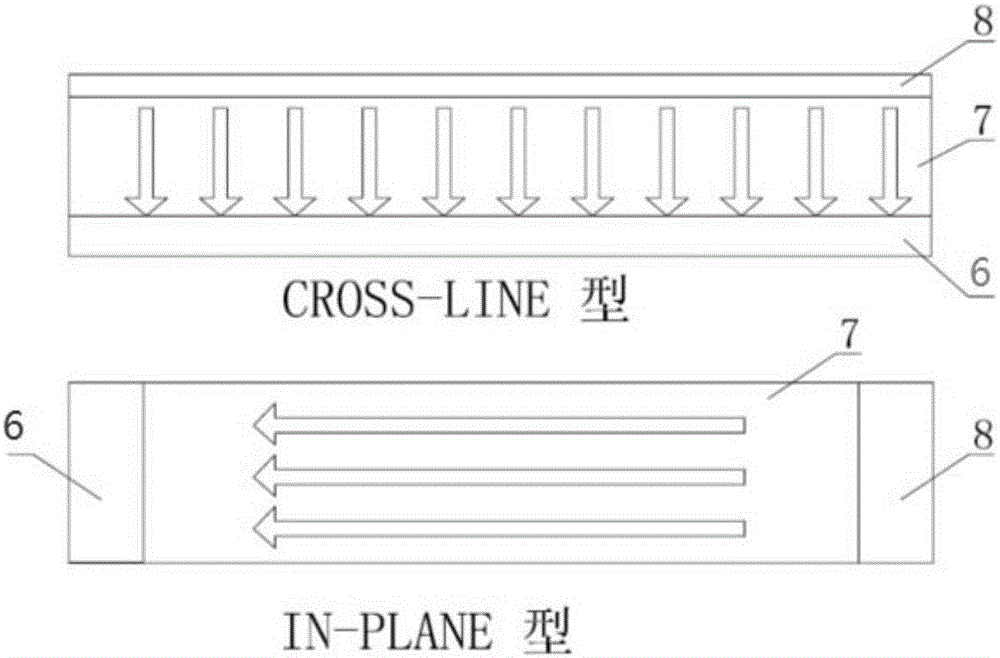

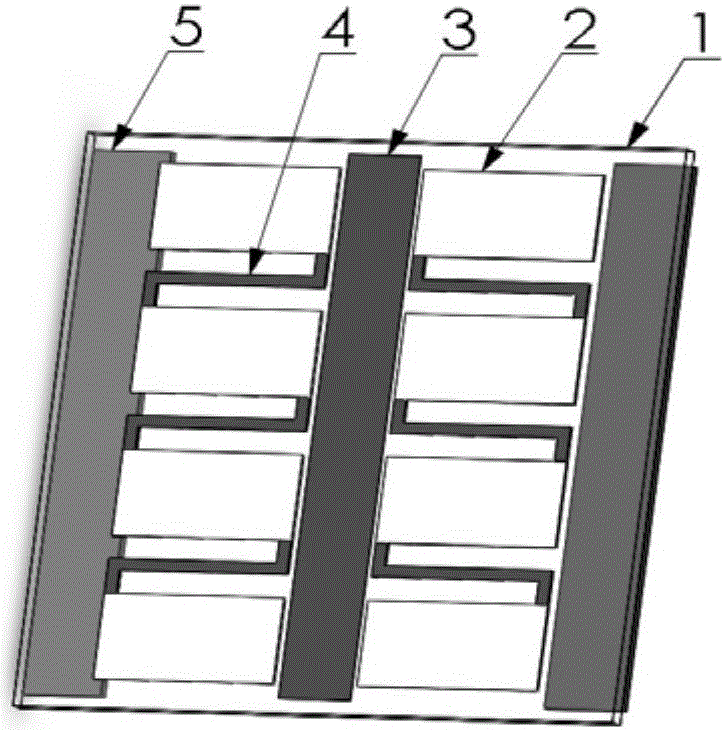

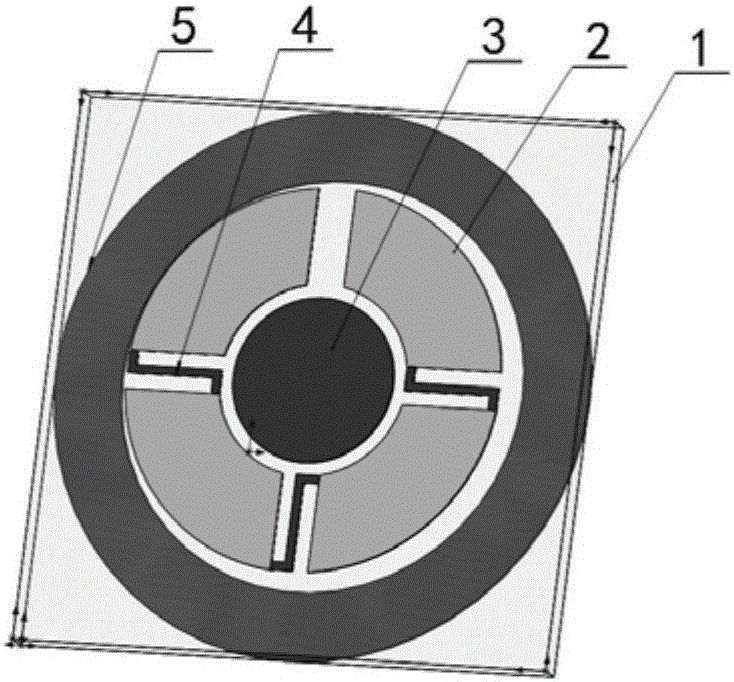

[0030] see Figure 1 to Figure 6 , a flexible silicon-based nano-thin film thermoelectric device, including a flexible glass substrate 1, on which a P-type silicon-based nano-thin film thermoelectric arm 2, a graphene electrode 4, a heat-end heat-absorbing graphene coating 5 and The graphene coating 3 for heat dissipation at the cold end, and the array of P-type silicon-based nano-film thermoelectric arms 2 are connected by graphene electrodes 4; The graphene coating 3 is disposed on the heat dissipation end surface of the flexible glass substrate 1 .

[0031] The P-type silicon-based nano-film thermoelectric arm 2 is prepared by magnetron sputtering. In the coating chamber, the background vacuum is 4.2×10 -4 Pa, after ignition and target washing for 10-15min, simultaneously turn on the Si target and Ge target for co-sputtering, and control the sputtering power of Si to 100W, and the sputtering power of Ge to 60W, and sputter for 6min. Then close the Si target and Ge target...

Embodiment 2

[0037] see Figure 1 to Figure 6 , a flexible silicon-based nano-thin film thermoelectric device, including a flexible glass substrate 1, on which a P-type silicon-based nano-thin film thermoelectric arm 2, a graphene electrode 4, a heat-end heat-absorbing graphene coating 5 and The graphene coating 3 for heat dissipation at the cold end, and the array of P-type silicon-based nano-film thermoelectric arms 2 are connected by graphene electrodes 4; The graphene coating 3 is disposed on the heat dissipation end surface of the flexible glass substrate 1 .

[0038] The P-type silicon-based nano-film thermoelectric arm 2 is prepared by magnetron sputtering. In the coating chamber, the background vacuum is 4.2×10 -4 Pa, after ignition and target washing for 10-15min, simultaneously turn on the Si target and Ge target for co-sputtering, and control the sputtering power of Si to 100W, and the sputtering power of Ge to 60W, and sputter for 6min. Then close the Si target and Ge target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com