A high-magnification olivine-type phosphate nano-flake positive electrode material and its preparation method

A nano-flake and olivine-type technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of shape, size unevenness, and rate performance that are difficult to meet the needs of new energy vehicle applications, etc. problem, to achieve the effect of uniform size, improved conductivity, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

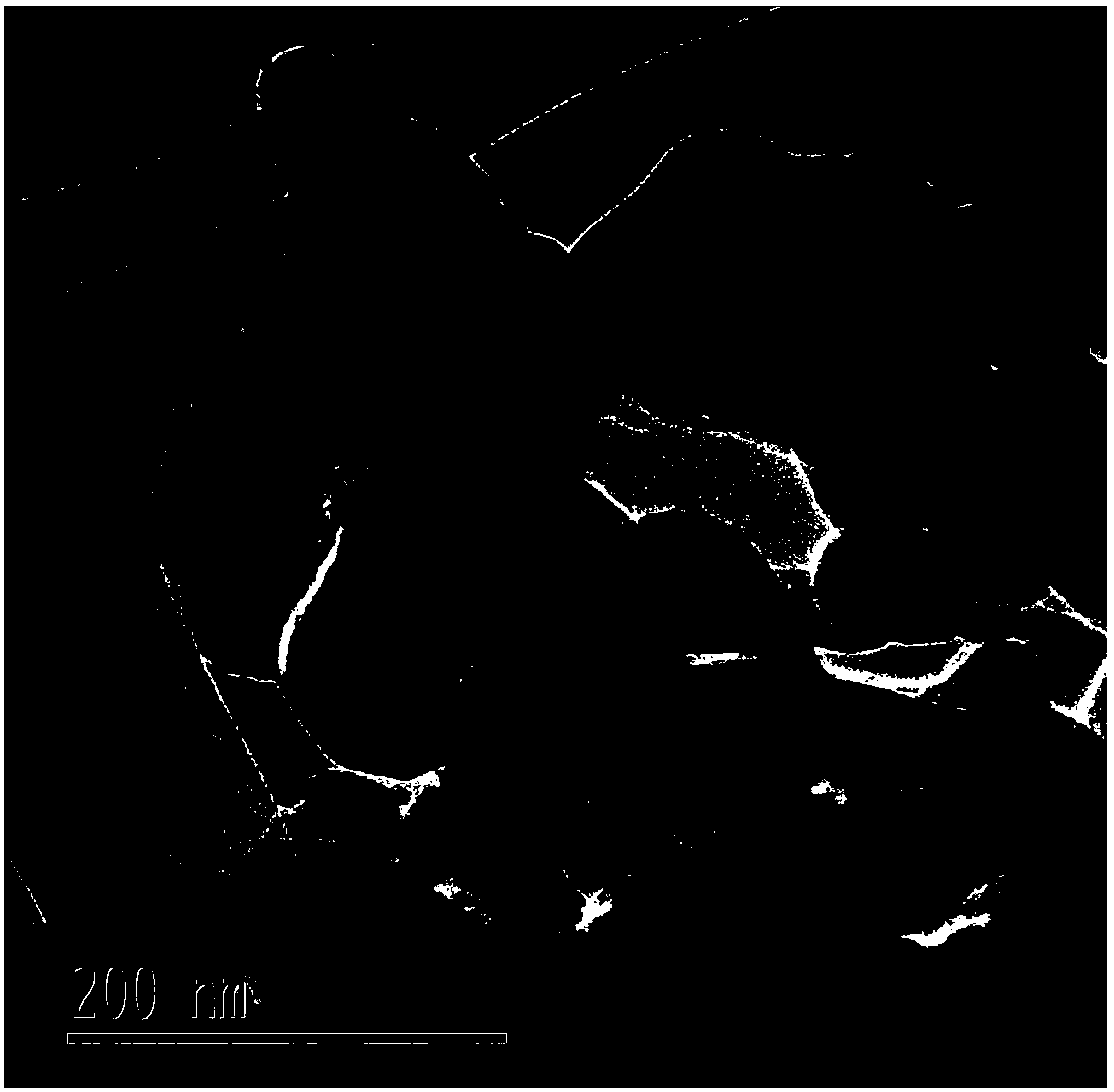

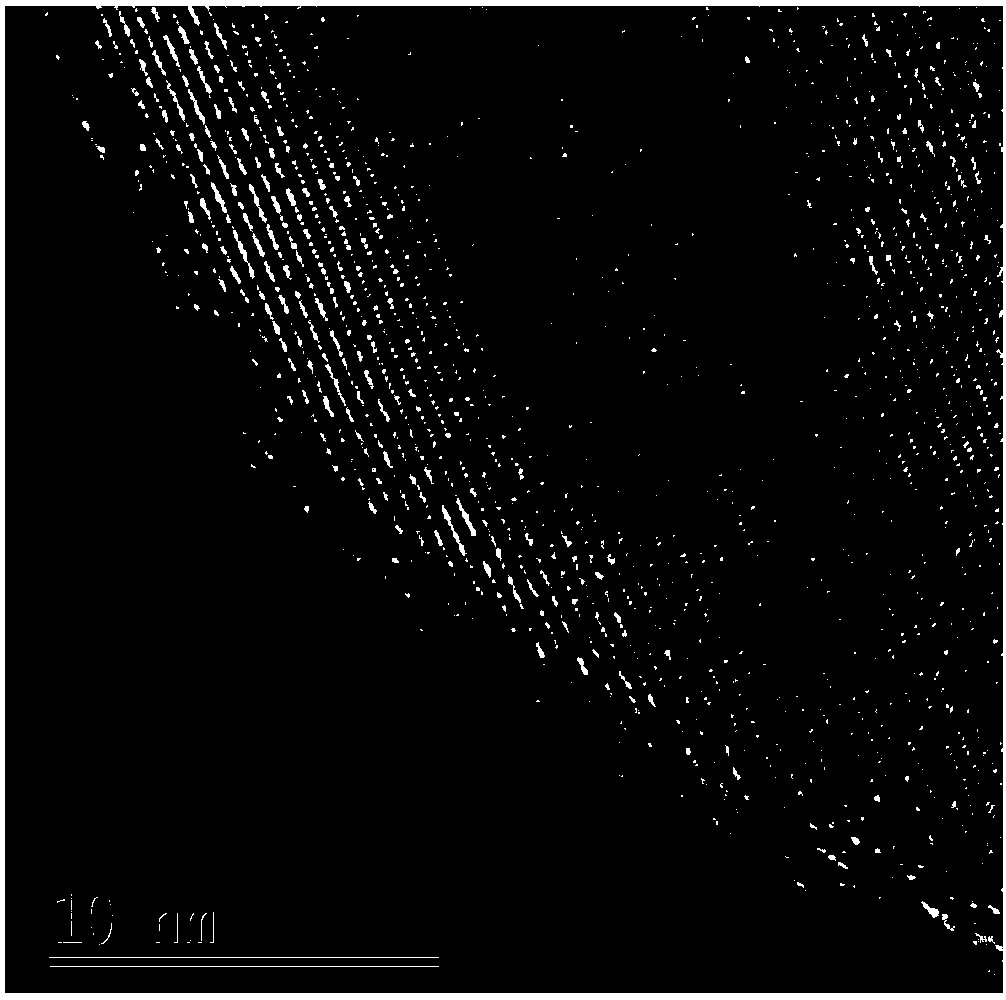

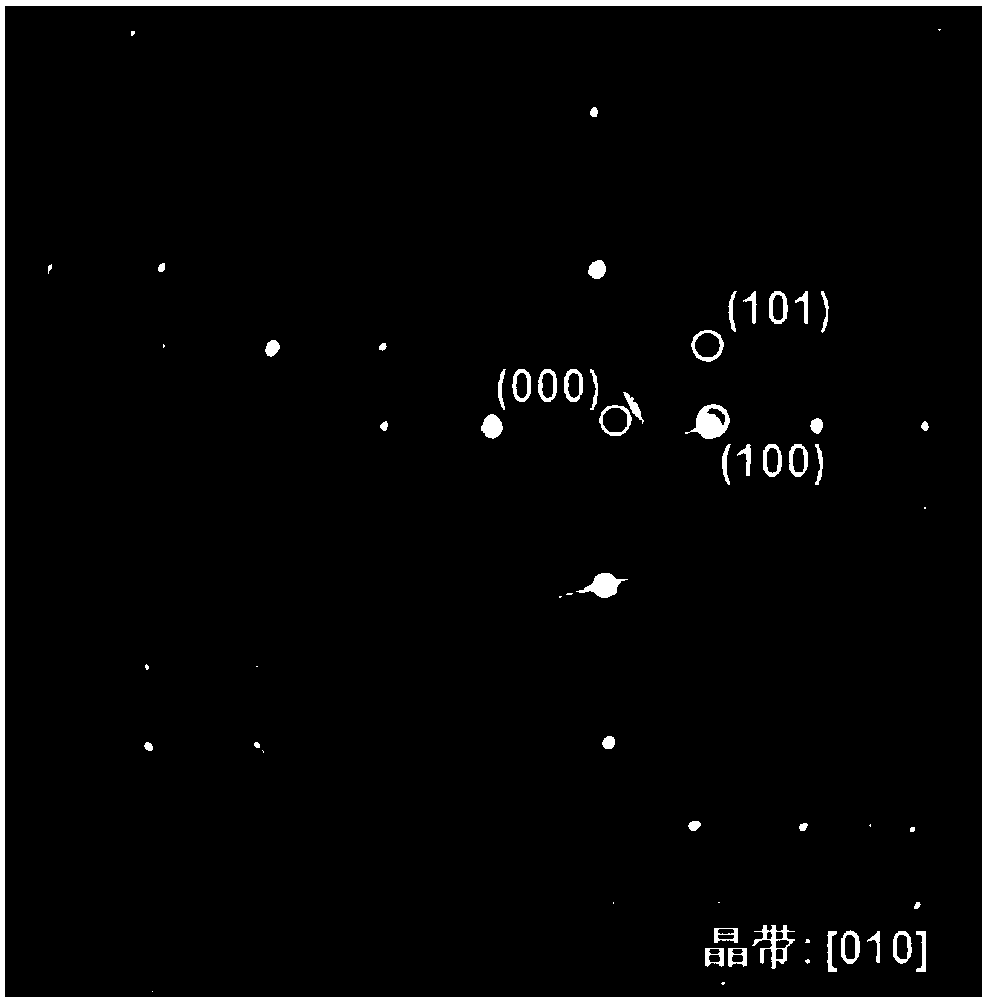

[0038] A high-magnification olivine-type phosphate nano-flake cathode material of this embodiment, the olivine-type phosphate cathode material LiMPO 4 (M stands for Fe, Mn or Co element) in nanosheet structure, nanosheet LiMPO 4 The thickness is 3-8nm, which can significantly improve the LiMPO 4 The rate performance of the positive electrode material can meet the high power demand of lithium-ion batteries for new energy vehicles. The aforementioned LiMPO 4 The surface is covered with a uniform carbon layer, which further improves its electrical conductivity, and its performance is relatively stable.

[0039] The preparation method of the above-mentioned high-magnification olivine-type phosphate nano-flake positive electrode material of the present embodiment, the steps are:

[0040] (1) Accurately weigh 50mg NH 4 FePO 4 ·H 2 O powder was dissolved in 100 mL of deionized water, and then sheared and stirred at room temperature using a shearing stirrer. The power of the she...

Embodiment 2

[0053] The preparation method of the above-mentioned high-magnification olivine-type phosphate nano-flake positive electrode material of the present embodiment, the steps are:

[0054] (1) Accurately weigh 100mg NH 4 CoPO 4 ·H 2 O powder was dissolved in 50 mL of deionized water, and then sheared and stirred at room temperature using a shearing stirrer. The power of the shearing stirrer was: 200 W, the rate of shearing and stirring was 10000 r / min, and the time was 24 h. Then take the supernatant and centrifuge at 500r / min for 5min to remove the large particles that have not been peeled off, then take the supernatant and centrifuge at 8000r / min for 60min. Then, the product obtained after the first step of centrifugation is centrifuged and washed with ethanol solvent, the centrifugation rate is 6000r / min, the time is 60min, the number of washings is 3 times, and finally placed in an oven and dried at 60°C for 12h to obtain NH 4 CoPO 4 ·H 2 O nanoflakes.

[0055] (2) Weigh...

Embodiment 3

[0058] The preparation method of the above-mentioned high-magnification olivine-type phosphate nano-flake positive electrode material of the present embodiment, the steps are:

[0059] (1) Accurately weigh 50mg NH 4 PPML 4 ·H 2 O powder was dissolved in 500mL deionized water, and then sheared and stirred at room temperature using a shearing stirrer. The power of the shearing stirrer was: 500W, the rate of shearing stirring was 20000r / min, and the time was 5h. Then take the supernatant and centrifuge at 300r / min for 15min to remove the large particles that have not been peeled off, then take the supernatant and centrifuge at 12000r / min for 20min. Then, the product obtained after the first step of centrifugation is centrifuged and washed with ethanol solvent, the centrifugation rate is 9000r / min, the time is 20min, the number of washings is 5 times, and finally placed in an oven and dried at 60°C for 12h to obtain NH 4 PPML 4 ·H 2 O nanoflakes.

[0060] (2) Weigh 744mg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com