Vegetable salt and method for preparing suaeda salsa vegetable salt by adopting de-colorization technology utilizing diatomite

A technology of Suaeda salsa and plant salt, applied in the field of plant salt and the preparation of Suaeda salsa and plant salt by diatomite decolorization process, can solve the problem of low P content, I content and Ca content, and low sodium chloride content , Low plant salt yield and other issues, to achieve the effect of improving whiteness and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A method of preparing Suaeda salina plant salt by diatomite decolorization process

[0036] Include the following steps:

[0037] Step 1. Raw material processing

[0038] Select high-quality Suaeda salsa in the mature stage. After testing, the Na content in Suaeda salsa is 2.92mg / g, the potassium content is 3.28mg / g, the Mg content is 0.23mg / g, and the Pb content is 2.21mg / kg;

[0039] After picking fresh Suaeda salsa, wash it with water, cut it into small pieces of 2-4 cm, and dry it naturally until the water content is 10-13%.

[0040] Step 2. Crush

[0041] The sun-dried Suaeda salsa was crushed with a pulverizer; the power of the pulverizer was 5.5KW, the rotation speed was 3800r / min, the pulverization time was 15min, and the pulverization particle size was 80 mesh.

[0042] Step 3, heat extraction

[0043] The material-liquid ratio is 1:18, the extraction time is 5 hours, and the hot extraction is carried out under the action of a microwave with a fre...

Embodiment 2

[0058] Example 2 Single Factor Analysis Experiment of the Ultrasonic Frequency Used in Diatomite Decolorization

[0059]Adopt the method for Suaeda salsa extracting plant salt of embodiment 1, only change the ultrasonic frequency that adopts in the diatomite decolorization step, carry out embodiment 2-4; The ultrasonic frequency that embodiment 2-4 adopts is shown in Table 1;

[0060] The ultrasonic frequency that table 1 embodiment 2-4 adopts

[0061]

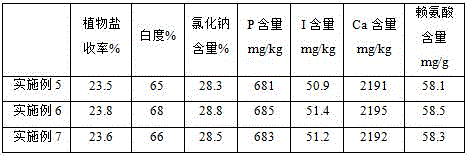

[0062] Adopt the method for embodiment 1-4, the result that extracts Suaeda salsa plant salt is shown in Table 2;

[0063] Table 2 adopts the result that embodiment 1-4 method extracts vegetable salt

[0064]

[0065] As can be seen from Table 2, Embodiment 3 is a preferred embodiment; the ultrasonic frequency used in the diatomaceous earth decolorization step is preferably 13.3 MHz.

Embodiment 5

[0066] Example 5 Single Factor Analysis Experiment of Diatomite Decolorization Extract Temperature

[0067] Adopt the method for Suaeda salsa extracting plant salt of embodiment 1, only change the temperature of the extract solution in the diatomite decolorization step, carry out embodiment 5-7; The temperature of the extract solution used in embodiment 5-7 is shown in Table 3;

[0068] The extract temperature that table 3 embodiment 5-7 adopts

[0069]

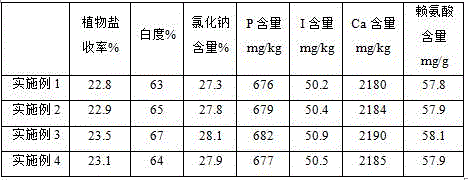

[0070] Adopt the method for embodiment 5-7, the result that extracts Suaeda salsa plant salt is shown in Table 4;

[0071] Table 4 adopts the result that embodiment 5-7 method extracts plant salt

[0072]

[0073] It can be seen from Table 4 that Example 6 is a preferred embodiment; the temperature of the extract solution in the diatomite decolorization step is preferably 21° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com