Plant salt and method for extracting plant salt from suaeda salsa through cellulase and pectinase

A technology of Suaeda salsa and cellulase, applied in the field of plant salt extraction, can solve the problems of low superoxide anion scavenging rate to hydroxyl radical scavenging rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 A kind of method adopting cellulase and pectinase to extract plant salt from Suaeda salsa

[0042] Include the following steps:

[0043] (1) Raw material pretreatment

[0044] The raw materials collected before Suaeda salsa flowering are dried in the sun, and the content of each element in Suaeda salsa per gram of dry weight is determined. The sodium content is 0.0683g / g, the ash content is 38.94%, the mercury content is 0.066mg / kg, and the arsenic content is 0.066mg / kg. The content is 0.3177mg / kg, and the lead content is 0.2385mg / kg. The dry Suaeda salsa is subjected to airflow crushing. The airflow crushing conditions are as follows: the pressure of the air storage tank is set to 0.9MPa; the screw feeding speed is 22hz; the classifier motor The frequency is set to 12hz, and the particle size of the crushed material is 250um.

[0045] (2) Hot dipping

[0046] Add Suaeda salsa powder to water for hot extraction, the ratio of solid to liquid is 1:21, the ...

Embodiment 2

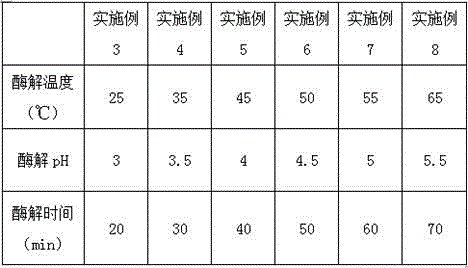

[0055] Embodiment 2 Combination factor analysis experiment

[0056] Using the method described in Example 1 to extract plant salt, only change the enzymatic hydrolysis temperature,

[0057] Enzymatic hydrolysis pH, enzymatic hydrolysis time factors, conduct experiments.

[0058] Table 1 Analysis experiment of combined factors of enzymatic hydrolysis temperature, enzymatic hydrolysis pH, and enzymatic hydrolysis time

[0059]

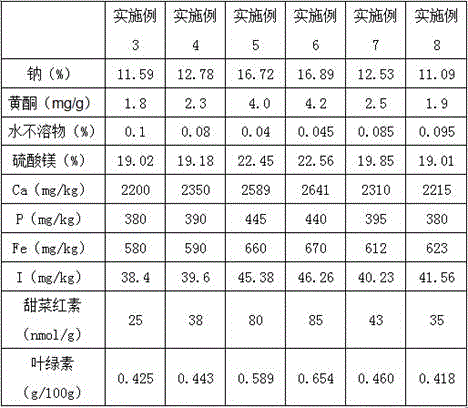

[0060] Table 2 Index of extracted vegetable salt

[0061]

[0062] The plant salt prepared by the invention does not detect heavy metals such as mercury, arsenic and lead.

[0063]Through the above experiments, embodiment 5 and embodiment 6 are preferred embodiments, that is, the enzymolysis temperature is preferably 45-50°C,

[0064] The pH of the enzymolysis is preferably 4-4.5, and the time of enzymolysis is preferably 40-50min.

[0065] The plant salts prepared in Example 5 and Example 6 were formulated into 2mg / ml aqueous solutions respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com