Selective laser forming metal powder preheating method and device

A metal forming and selective laser technology, which is applied in the field of additive manufacturing, can solve the problems of powder agglomeration, sharp increase in processing costs, and unusable powder, so as to reduce thermal stress and thermal deformation, improve the precision and surface quality of parts, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

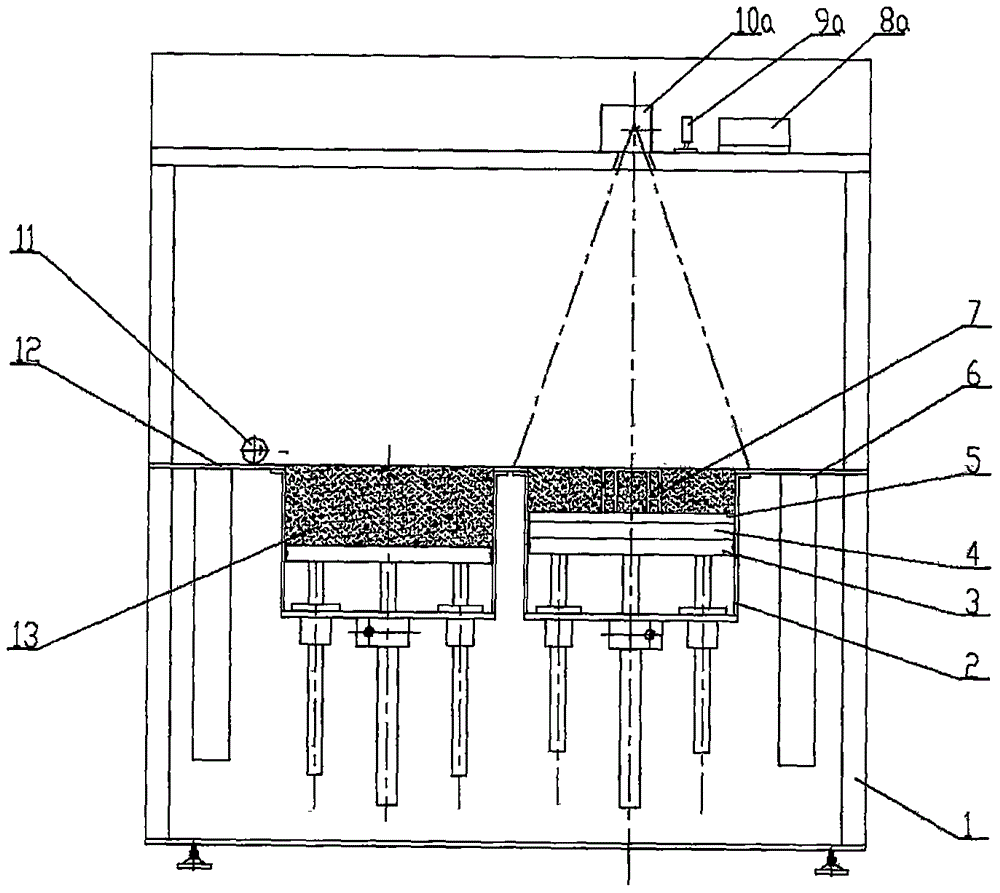

[0019] refer to figure 1 As shown, the metal powder preheating and scanning processing are the same laser scanning system. Before processing, the substrate heating device 4 first heats the substrate 5 to the required preheating temperature, and starts to spread the powder, and then according to the laser power and spot size of the metal powder preheating , scanning speed and other parameters to scan and heat the cross-section of the layer of the workpiece, and then scan and process the cross-section of the layer again according to the parameters of the workpiece processing, so that the cycle is repeated until the final processing is completed.

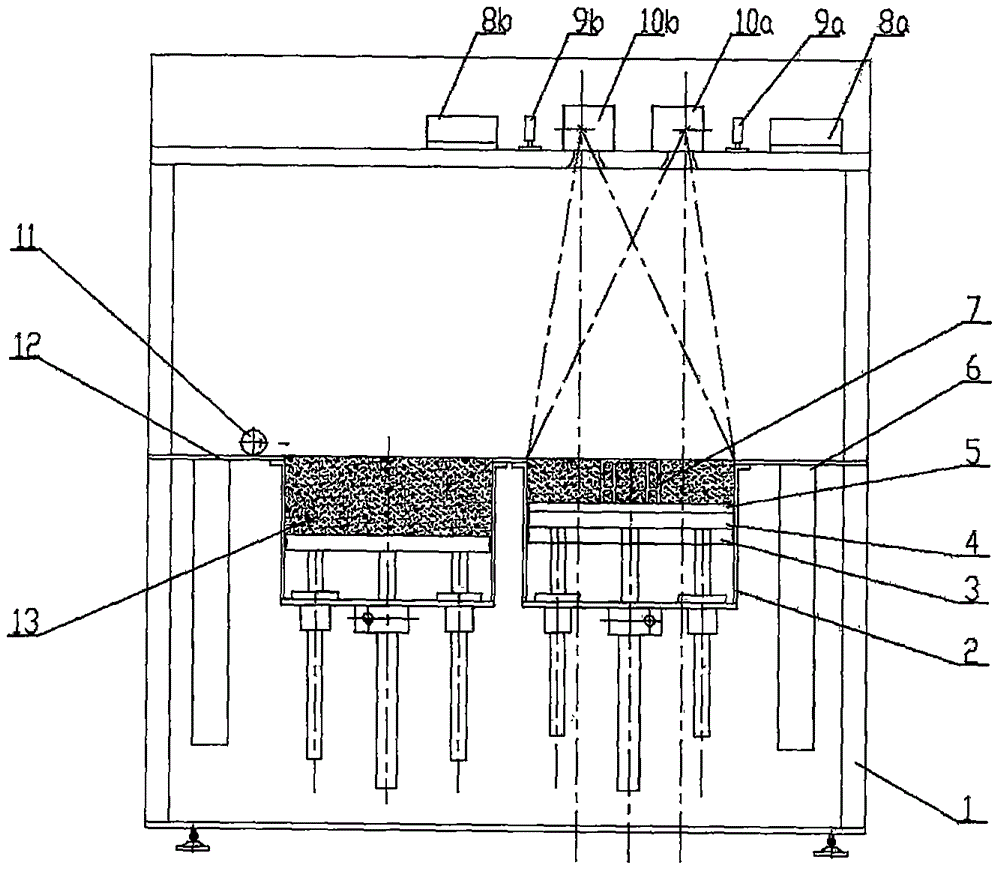

[0020] refer to figure 2 As shown, metal powder preheating and scanning processing each have an independent laser scanning system. Before processing, the substrate heating device 4 firstly heats the substrate 5 to the required preheating temperature, starts to spread the powder, and then the preheating laser scanning system checks the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com