Method for preparing silicon sol by using tubular slurry reactor

A slurry reactor and tube-and-tube technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

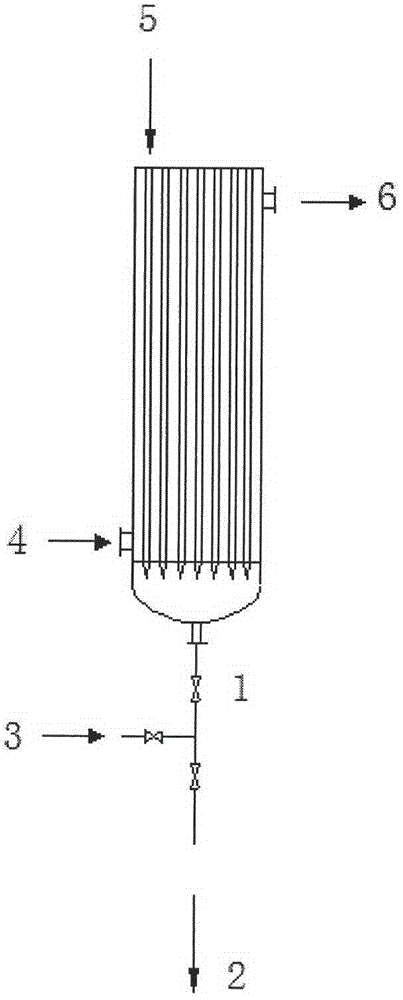

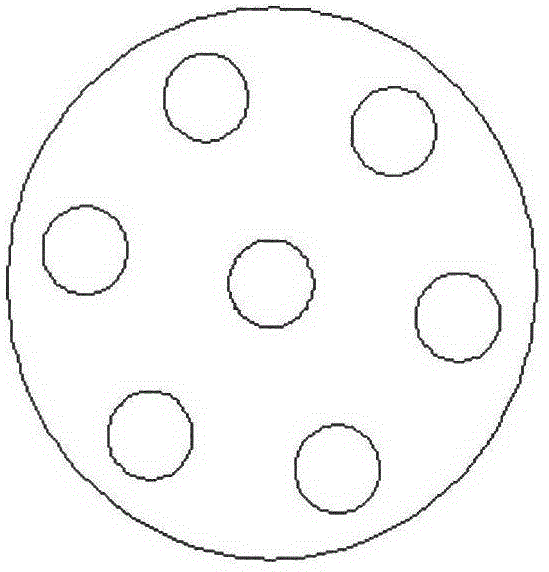

[0022] A method for preparing silica sol in a tubular slurry reactor, its components are calculated in parts by mass, comprising the following process steps:

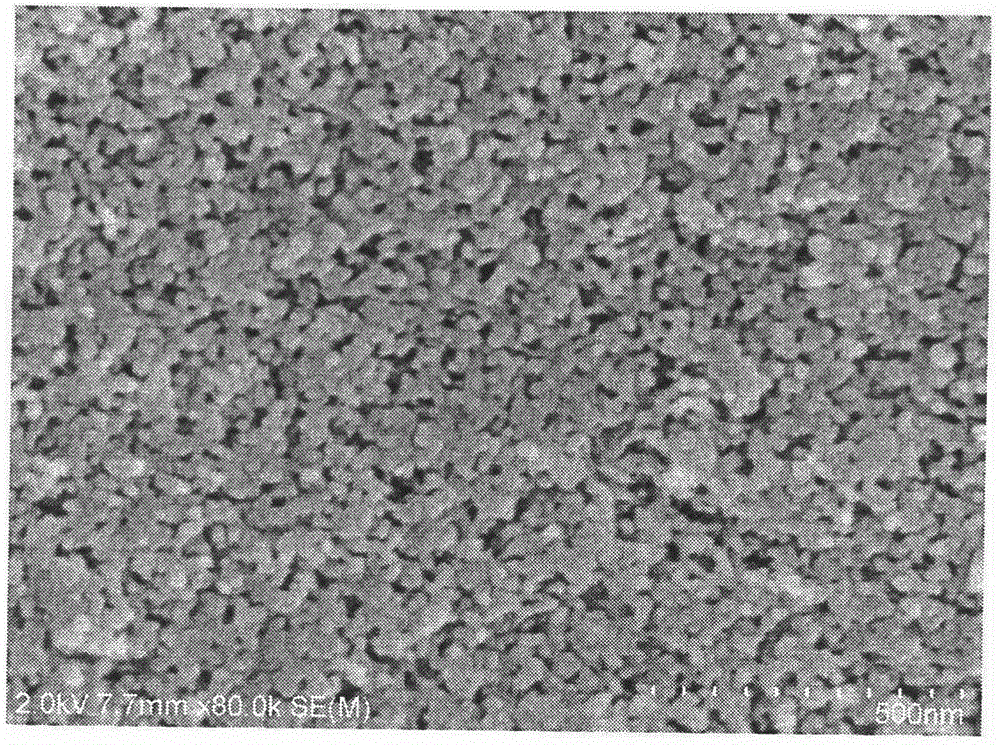

[0023] The particle size of silicon powder is 100 mesh, and the addition amount is 20 parts, added in 4 times; the lye is composed of 0.5 parts of KOH and 99.5 parts of water. The height of the reactor is 0.7m, and it is formed by arranging 6 slurry reaction tubes with an inner diameter of 14mm. The aspect ratio is 50:1. The outer diameter of the slurry reactor is 0.06m; the reaction temperature is 50°C, and the reaction time is 2 hours. The particle size of the obtained silica sol was 14 nm. image 3 A scanning electron microscope of silica sol was obtained for this example.

Embodiment 2

[0025] A method for preparing silica sol in a tubular slurry reactor, its components are calculated in parts by mass, comprising the following process steps:

[0026] The particle size of the silicon powder is 300 mesh, and the addition amount is 60 parts, added in 5 times; the lye consists of 0.5 parts of KOH, 0.5 parts of NaOH and 99 parts of water. The height of the reactor is 5m, and it is formed by arranging 60 slurry reaction tubes with an inner diameter of 20mm. The aspect ratio is 250:1. The outer diameter of the slurry reactor is 0.15m; the reaction temperature is 65°C, and the reaction time is 12 hours. The particle diameter of the obtained silica sol was 32 nm. Figure 4 A scanning electron microscope of silica sol was obtained for this example.

Embodiment 3

[0028] A method for preparing silica sol in a tubular slurry reactor, its components are calculated in parts by mass, comprising the following process steps:

[0029] The particle size of the silicon powder is 300 mesh, and the addition amount is 40 parts, added in 4 times; the lye is composed of 0.5 parts of NaOH and 99.5 parts of water. The height of the reactor is 4m, and it is formed by arranging 14 slurry reaction tubes with an inner diameter of 50mm. The aspect ratio is 80:1, and the outer diameter of the slurry reactor is 0.5m; the reaction temperature is 90°C, and the reaction time is 10 hours. The particle size of the obtained silica sol was 21 nm. Figure 5 A scanning electron microscope of silica sol was obtained for this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com