A thin-layer pavement pavement ultra-sticky wear layer and its construction method

A construction method and a wear layer technology, which are applied to the construction of thin-layer pavement super-stick wear layer, and the field of thin-layer road pavement super-stick wear layer, can solve the problem of unsatisfactory economic and social benefits, surface aggregate bulge Poor flatness, insufficient bonding strength and other problems, to achieve the effect of enhancing the rolling function of driving, low driving noise, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

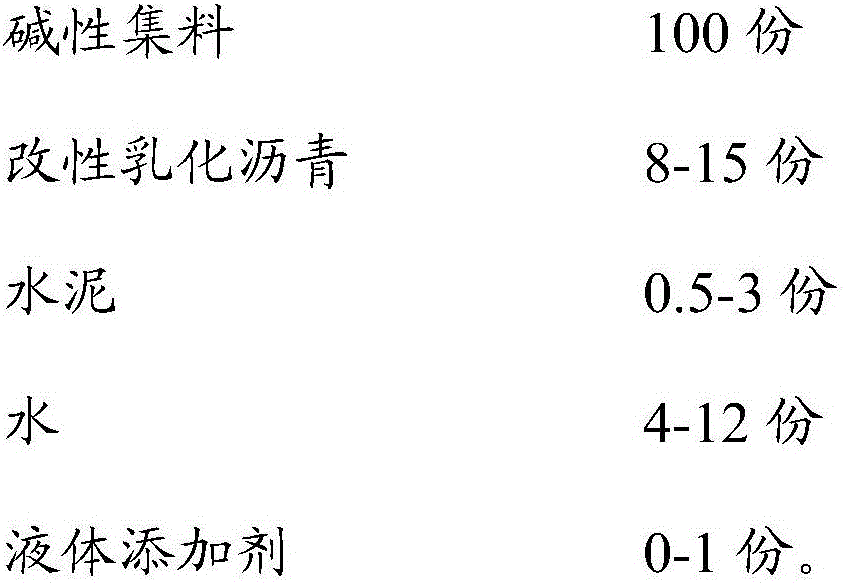

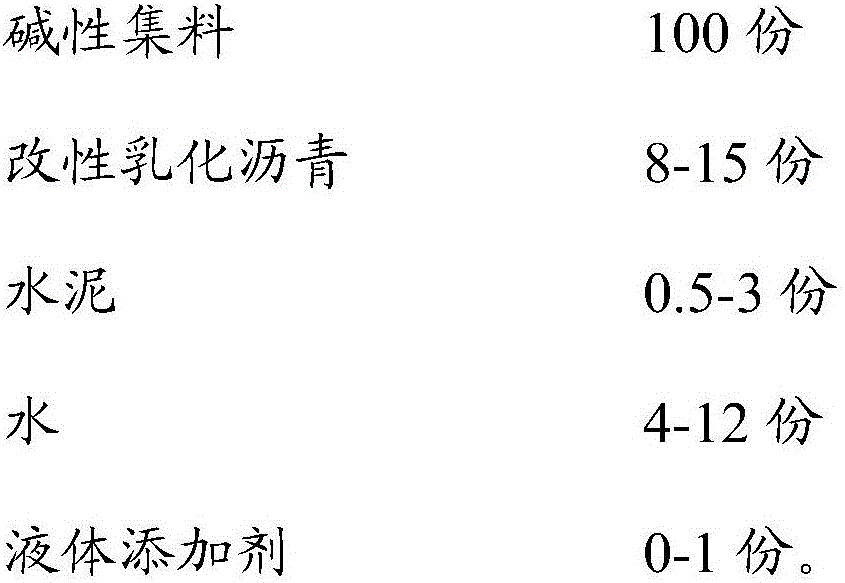

[0043]A kind of ultra-sticky wear layer for pavement pavement, which is prepared from the following components in parts by mass:

[0044]

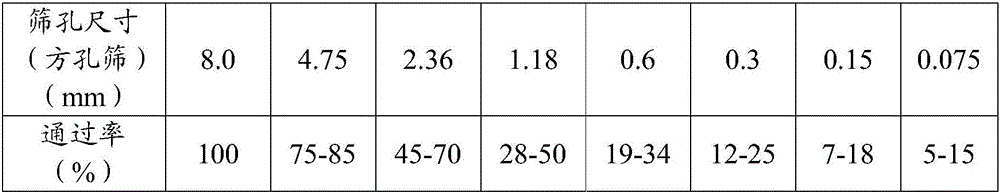

[0045] Among them, the amount of SBS modifier in the emulsion is 2.5%, the weight ratio of SBS modifier and SBR modifier is 1:1, and the emulsifier is QD-PS1 cationic slow cracking and fast cracking agent produced by Jiangmen Qiangqiang Road Material Co., Ltd. The emulsifying agent, the particle size of diabase is 0-8mm, the coarse and fine aggregates meet the "Quality Requirements for Coarse and Fine Aggregate for Microsurfacing and Slurry Sealing", and the maximum particle size is 8mm. The gradation adopts "Special Grading for Superviscous Abrasion Layer Aggregate", and the aggregate screening test results are shown in Table 2:

[0046] Table 2 Sieving test results of aggregates in super viscous wearing layer

[0047]

[0048] The steps of the construction method for paving the super-sticky wear layer on the thin-layer pavement ar...

Embodiment 2

[0052] A kind of ultra-sticky wear layer for pavement pavement, which is prepared from the following components in parts by mass:

[0053]

[0054] Among them, the amount of SBS modifier in the emulsion is 2.7%, the weight ratio of SBS modifier and SBR modifier is 5:1, the particle size of diabase is 0-8mm, and the coarse and fine aggregates meet the "micro-surface "Quality Requirements for Coarse and Fine Aggregate Used for Treatment and Slurry Sealing Layer", the maximum particle size is 8mm. The gradation adopts "Special Grading for Superviscous Abrasion Layer Aggregate", and the aggregate screening test results are shown in Table 3:

[0055] Table 3 Sieving test results of aggregates in super viscous wearing layer

[0056]

[0057] The steps of the construction method for paving the super-sticky wear layer on the thin-layer pavement are as follows:

[0058] First put diabase, modified emulsified asphalt, cement, and water on the slurry seal vehicle, and mix at 35°C...

Embodiment 3

[0061] A kind of ultra-sticky wear layer for pavement pavement, which is prepared from the following components in parts by mass:

[0062]

[0063] Among them, the amount of SBS modifier in the emulsion is 3.3%, the weight ratio of SBS modifier and SBR modifier is 3:1, and the emulsifier is QD-PS1 cationic slow cracking and fast cracking agent produced by Jiangmen Qiangqiang Road Material Co., Ltd. The emulsifying agent, the particle size of diabase is 0-8mm, the coarse and fine aggregates meet the "Quality Requirements for Coarse and Fine Aggregate for Microsurfacing and Slurry Sealing", and the maximum particle size is 8mm. The gradation adopts "Special Grading for Superviscous Abrasion Layer Aggregate", and the aggregate screening test results are shown in Table 4:

[0064] Table 4 Sieving test results of superviscous wearing layer aggregates

[0065]

[0066] The steps of the construction method for paving the super-sticky wear layer on the thin-layer pavement are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com