DMAPS-AA-AAS (N,N-dimethyl(methylacryloyloxyethyl)aminopropanesulfonic acid inner salt-acrylic acid-sodium acrylate) copolymer, and preparation method and application thereof

A DMAPS-AA-AAS, 1. DMAPS-AA-AAS technology, applied in the field of polymer preparation and application, can solve the problems of limited effect and single effect, and achieve good biocompatibility and bionicity, The effect of simple operation and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 20g monomer DMAPS and 80g monomer AA into the reaction vessel, add a certain amount of deionized water and stir evenly; make the total amount of monomer DMAPS and AA account for 20% by mass of the total amount of the aqueous solution; Ammonium sulfate is made into a 1wt% aqueous solution, and when the temperature of the water bath rises to 65°C, it is added dropwise into the reaction vessel with a dropping funnel; the reaction is kept for 5 hours, and after the reaction is completed, the material can be discharged after cooling to room temperature, and DMAPS is obtained. - AA copolymers. Then add the sodium hydroxide solution of 10wt% concentration in the DMAPS-AA copolymer of 10% concentration, adjust pH value 3.0~3.5, stir 3 hours, make part of acrylic acid in the copolymer convert into sodium acrylate (AAS), make sodium acrylate The content accounts for 30% of the total monomer content, and a DMAPS-AA-AAS copolymer with an AAS content of 30% is prepared.

Embodiment 2

[0032] Add 20g monomer DMAPS and 80g monomer AA into the reaction container, add a certain amount of deionized water and stir evenly; make the total amount of monomer DMAPS and AA account for 20% by mass of the total aqueous solution; under nitrogen protection, persulfuric acid Ammonium is made into a 1wt% aqueous solution, and when the temperature of the water bath rises to 65°C, it is added dropwise into the reaction container with a dropping funnel, and the reaction is kept for 5 hours. AA copolymer. Then add the sodium hydroxide solution of 10wt% concentration in the DMAPS-AA copolymer of 10% concentration, adjust pH value 5.5~6.0, stir 3 hours, make part of acrylic acid in the copolymer convert into sodium acrylate (AAS), make sodium acrylate The content accounts for 60% of the total monomer content, and a DMAPS-AA-AAS copolymer with an AAS content of 60% is prepared.

Embodiment 3

[0034] Add 20g monomer DMAPS and 80g monomer AA into the reaction container, add a certain amount of deionized water and stir evenly; make the total amount of monomer DMAPS and AA account for 20% by mass of the total aqueous solution; under nitrogen protection, the initiator Ammonium persulfate is made into a 1wt% aqueous solution, and when the temperature of the water bath rises to 65°C, it is added dropwise to the reaction container with a dropping funnel; it is kept for 5 hours, and after the reaction is completed, it can be discharged after cooling to room temperature. DMAPS-AA copolymer. Then add the sodium hydroxide solution of 10wt% concentration in the DMAPS-AA copolymer of 10% concentration, adjust pH value 7.0~7.5, stir 3 hours, make all acrylic acid in the copolymer convert into sodium acrylate (AAS), make sodium acrylate The content accounts for 80% of the total monomer content, and the DMAPS-AA-AAS copolymer with 80% AAS content is prepared.

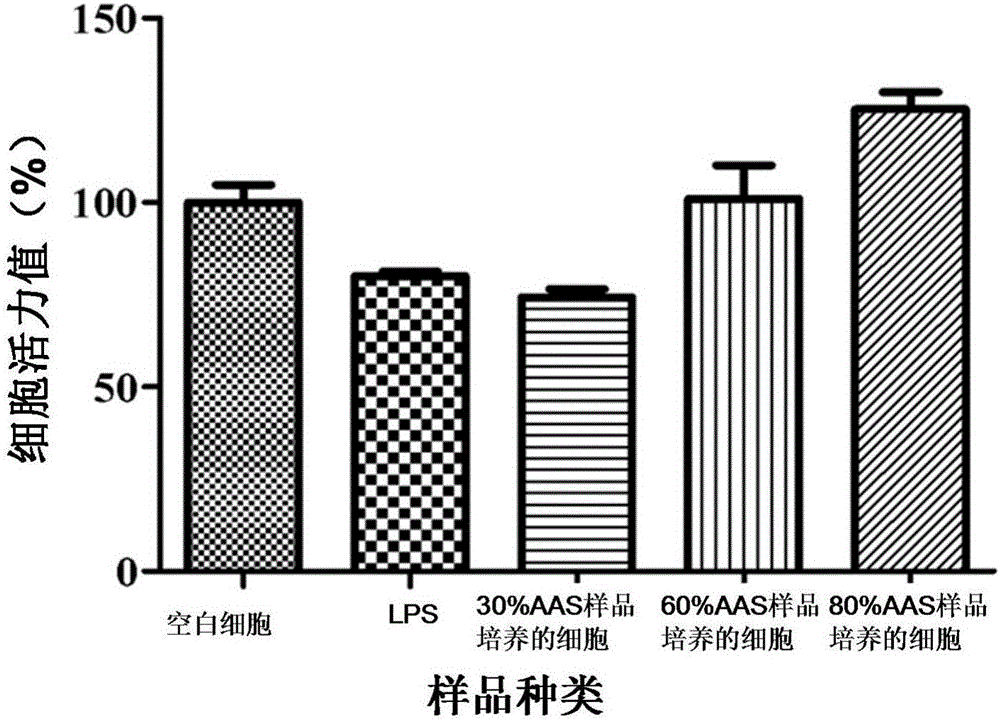

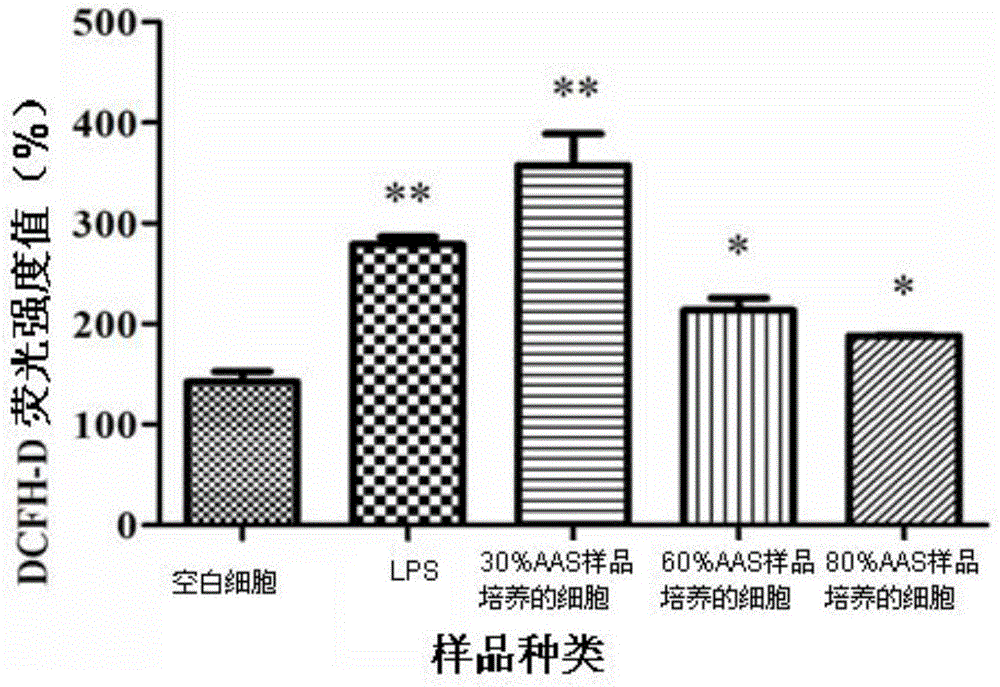

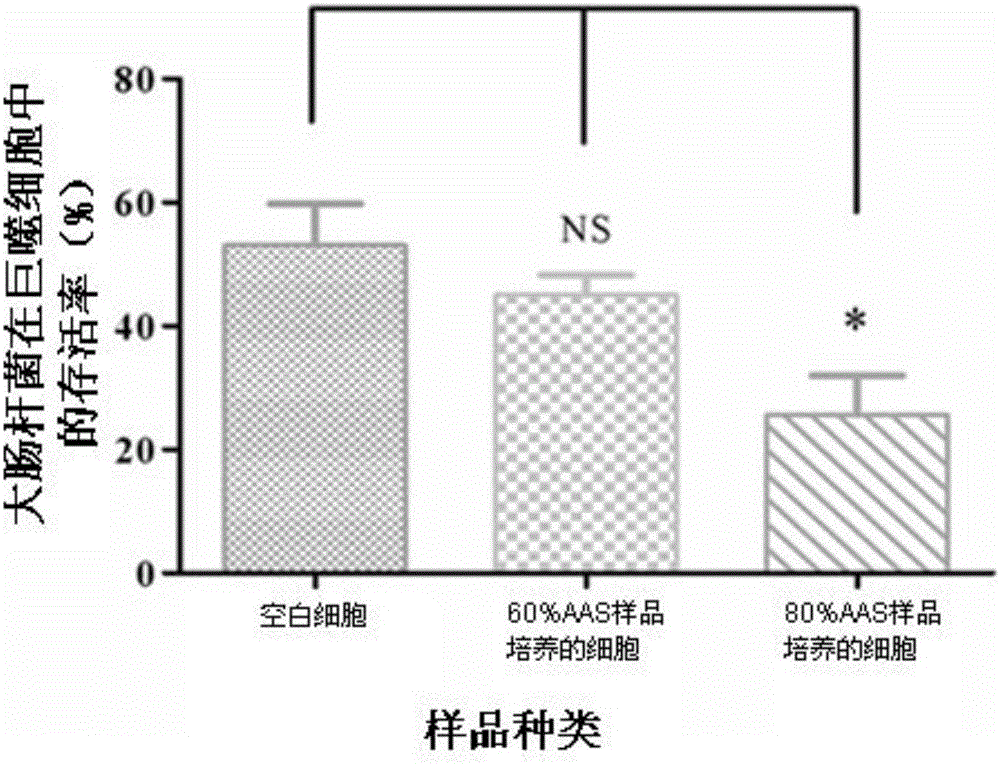

[0035] The biologic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com