Method and system for producing pure cotton pulp in dry cutting method

A cutting method, pure cotton technology, applied in pulp beating/refining method, dryer section, pulp dehydration, etc., can solve the problems of increasing cutting time, large investment in continuous production, and substandard quality, so as to reduce production capacity consumption, solve quality deterioration, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

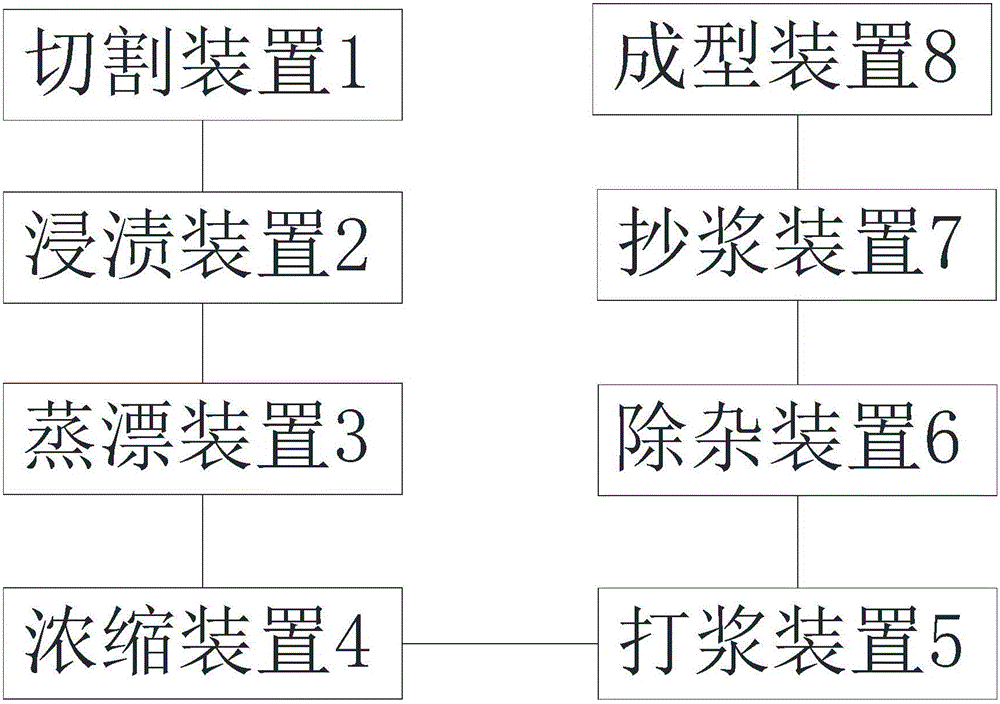

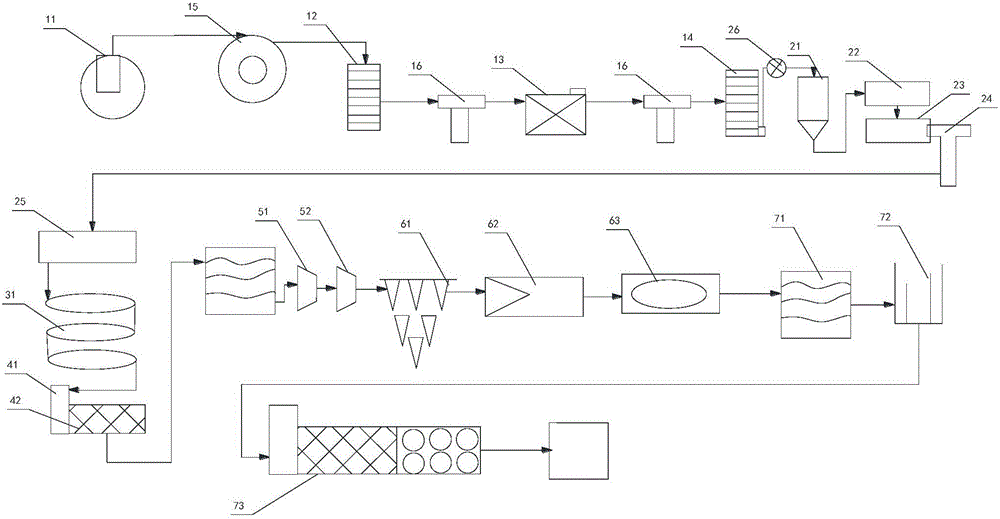

[0042] The present invention provides a method and system for producing pure cotton pulp by a dry cutting method. The method for producing pure cotton pulp by a dry cutting method comprises the following steps:

[0043] (1) Cotton catching and dry cutting: catching cotton with a disc catching machine, transporting the material to the first vibrating cotton box through the cotton suction fan, and feeding the cotton to the dry cutting machine with the first vibrating cotton box for cutting, cutting The final material is evenly adjusted by the second vibrating cotton box;

[0044] (2) Alkali blending and impregnation: The temperature of alkali blending is controlled at 59-62°C, with NaOH at 4%-6% relative to the dry pulp weight, hydrogen peroxide at 0.8%-1.5% relative to the absolute dry pulp weight, and detergent relative to absolute dry pulp. The dry pulp weight is: 0.01%-0.05%, and the deionizer is 0.01%-0.2% relative to the absolute dry pulp weight; the homogenized material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com