PVC (polyvinyl chloride) steel belt winding pipe

A technology of winding pipes and steel strips, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high cost, poor performance of drainage pipes, increase the degree of water pollution, etc., and achieve low cost and less plastic cracking. , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

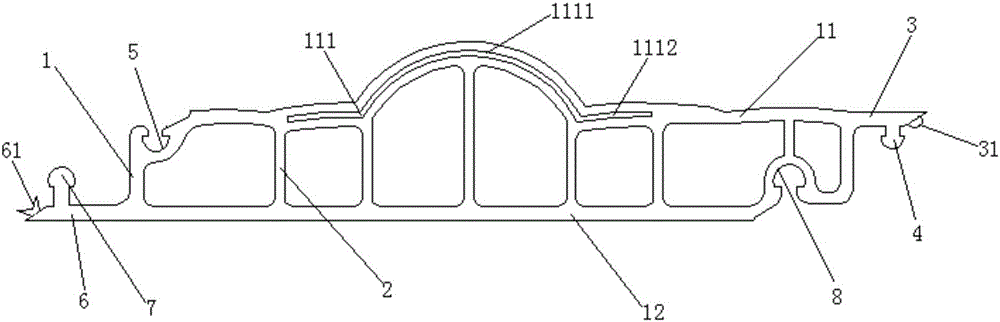

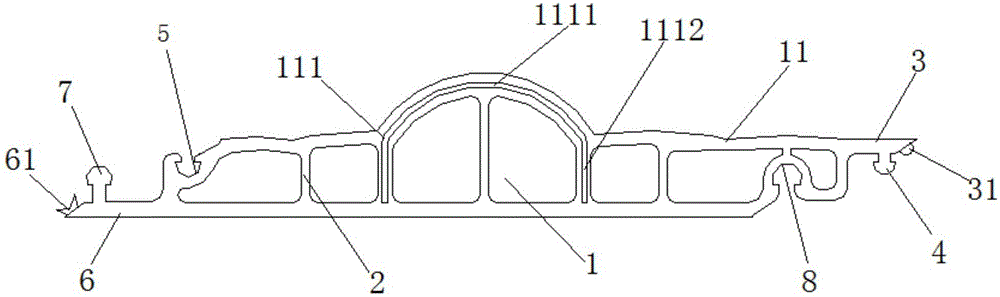

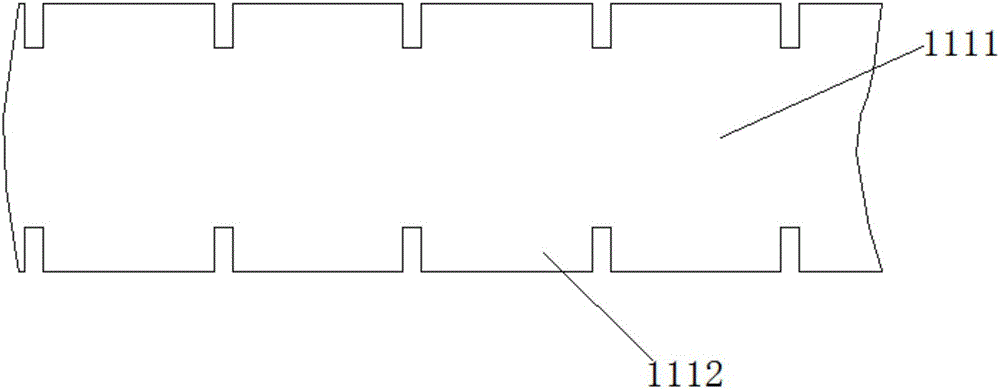

[0029] Such as figure 1 , figure 2 A PVC steel belt winding pipe is shown, which includes a steel belt winding belt 1, and the steel belt winding belt 1 includes an upper winding belt 11 and a lower winding belt 12; the upper winding belt 11 is internally provided with a steel belt 111 , the steel strip 111 includes an arc-shaped steel strip 1111 and an extended steel strip 1112, the two sides of the arc-shaped steel strip 1111 are respectively connected with an extended steel strip 1112; There are a plurality of support belts 2; the support belt 2 of the steel belt winding belt 1 forms a plurality of separate inner cavities, and an upper connection extension belt 3 is arranged on one side of the upper winding belt 11, and an upper connection extension belt 3 is arranged on the upper connection extension belt 3. There is an upper connection card head buckle tenon 4, and the other side of the upper winding belt 11 is provided with an upper connection card groove buckle tenon ...

Embodiment 2

[0033] This embodiment has been further improved on the basis of embodiment 1, as figure 1In the PVC steel belt winding pipe shown, the upper connection extension belt and the lower connection extension belt are both provided with sealing rubber strips.

Embodiment 3

[0035] This embodiment has been further improved on the basis of embodiment 2, such as figure 1 , figure 2 In the PVC steel belt winding pipe shown, the upper connection extension belt is provided with an O-shaped sealing strip, and the lower connection extension arm is provided with a Y-shaped sealing strip. This embodiment is a non-pressure self-flowing pipeline , the internal and external pressures are both atmospheric pressure, but under the action of water flow, the osmotic pressure of water is greater than atmospheric pressure, so the sealing ring of the inner rule adopts Y-shaped sealing strip, and the Y-shaped piece of the Y-shaped sealing strip is inside the water flow. Under the action of the seal, it is firmly attached to the sealed part. After the water pressure is decompressed by the Y-shaped sealing strip, the internal and external pressure is basically equal to the atmospheric pressure. At this time, under the elastic deformation of the O-shaped sealing strip, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com