Economizer increasing fume temperature at SCR inlet by changing areas and flowing modes

A flow mode and economizer technology, applied in feed water heaters, lighting and heating equipment, preheating, etc., can solve problems such as low denitrification efficiency, incomplete denitrification, and low flue gas reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention includes specific implementation steps.

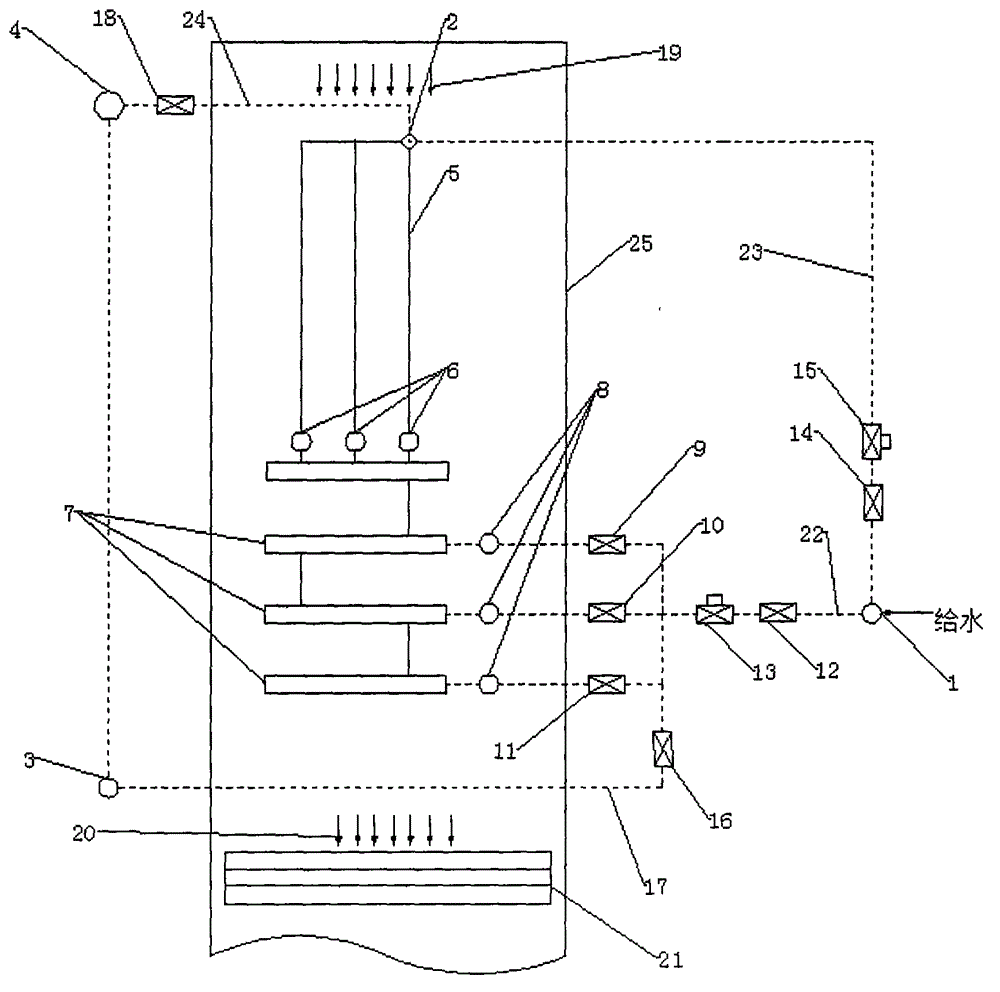

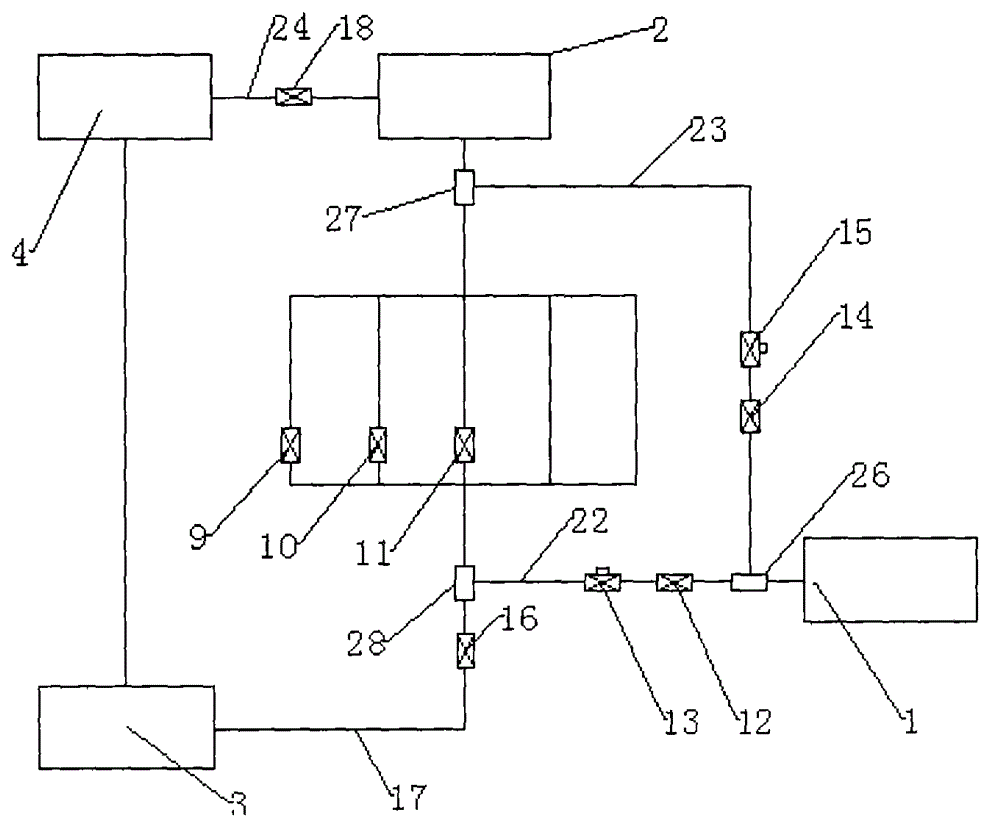

[0013] Such as figure 1 and figure 2 As shown, an economizer that changes the area and flow mode to increase the flue temperature at the SCR inlet, including the furnace flue shell 25, the economizer outlet A header 2 located in the furnace flue shell 25, and the economizer A group of economizer suspension pipes 5 connected to outlet A header 2, an economizer intermediate header 6 connected to each economizer suspension pipe 5, and a set of economizer middle A group headers 6 connected A group of economizer serpentine pipes 7, the middle group B header of the economizer connected to the economizer serpentine pipe 7, and the SCR reactor 21 connected to the bottom of the furnace flue shell 26; the inlet of the economizer A first branch 22 is provided between the header 1 and the intermediate headers 8 of the economizer group B. The first branch 22 is provided with a cut-off valve 12 and a flow regulating v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com