Method for measuring magnesium and zinc content in alloy at same time and application thereof

A technology of zinc content and alloy, which is applied in chemical analysis by titration method, analysis by causing chemical reaction of materials, material analysis by observing the influence of chemical indicators, etc. It can solve the problem of long analysis time and potential titration of zinc. End point delay, measurement inconvenience and other problems, to achieve the effect of simple and fast method, shorten the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

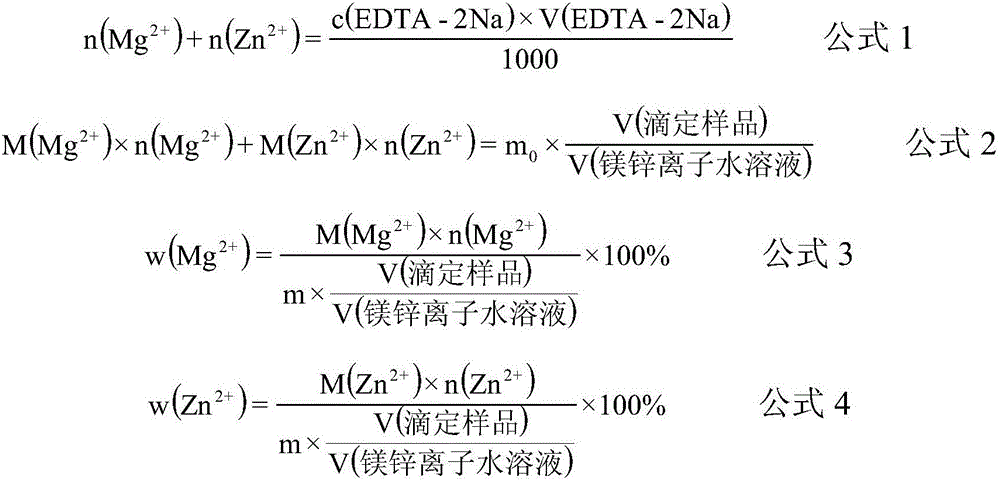

Examples

Embodiment 1

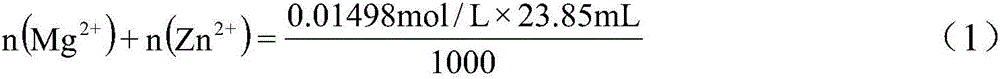

[0023] In step one, weigh 0.9114g of a bright and clean alloy, which only contains magnesium and zinc, that is to say, the alloy is a magnesium-zinc alloy with a purity of 100%; add 6mol / L hydrochloric acid dropwise to the alloy The aqueous solution, after it is completely dissolved, is heated and stirred until slightly boiling to obtain the first solution; the first solution is transferred to a 200.00mL volumetric flask, diluted with deionized water, fixed to volume, and shaken to obtain an aqueous solution of magnesium and zinc ions. Preferably, for the accuracy of subsequent titration endpoint judgment, the concentration of the prepared magnesium and zinc ion aqueous solution is preferably 0.14 mol / L-0.2 mol / L.

[0024] In this step, the purpose of heating and stirring until slightly boiling is to remove the excess hydrochloric acid aqueous solution used when dissolving the alloy, so as to reduce the acidity of the first solution.

[0025] In step 2, accurately pipette 2.00...

Embodiment 2

[0036]In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the similarities with Embodiment 1 will be described. The difference between embodiment 2 and embodiment 1 is that in step one, the quality of the alloy is 1.1025g; in step two, the volume of the titration sample is 5.00mL; The dosage concentration is 0.05096mol / L, and the volume dosage of the EDTA-2Na aqueous solution is 18.57mL; in step 4, the calculated mass percentages of magnesium and zinc in the alloy are 73.64% and 26.36%, respectively.

Embodiment 3

[0038] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that in step one, the quality of the alloy is 0.9879g; in step two, the volume of the titrated sample is 10.00mL; The dosage concentration is 0.1011mol / L, and the volume dosage of the EDTA-2Na aqueous solution is 14.60mL; in step 4, the calculated mass percentages of magnesium and zinc in the alloy are 56.43% and 43.57%, respectively.

[0039] It is worth noting that, because the alloys in the above-mentioned Examples 1-3 are all magnesium-zinc alloys with a purity of not less than 99.9%, it can be approximately considered that the purity of the alloy reaches 100%. Therefore, the quality of the alloys in the above-mentioned Examples 1-3 It is equal to the total mass of magnesium and zinc in the alloy. Certainly, the method for simultaneously measuring magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com