Transparent conductive film and manufacturing method thereof

A technology of transparent conductive film and conductive film, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, equipment for manufacturing conductive/semiconductive layer, etc. Issues such as flexible substrate surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

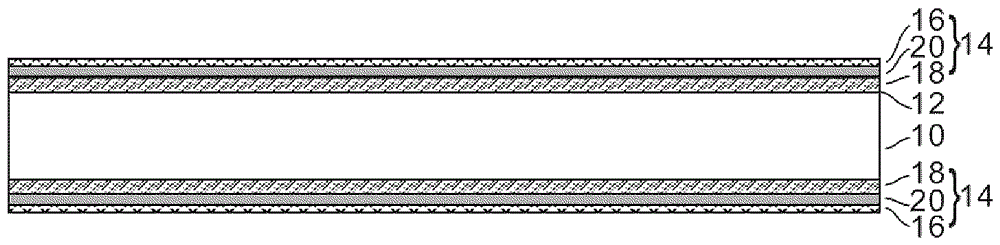

[0077] This embodiment relates to an undoped metal oxide type transparent conductive film.

[0078] First, glass with a thickness of 500 μm is selected as the transparent substrate. Then, a conductive layer is formed on the surface of the glass by using a treatment method of ion implantation followed by plasma deposition.

[0079] In the ion implantation process, ZnO was selected as the vacuum cathode arc target material, the process temperature of the ion implantation was controlled at 600°C, and the vacuum was pumped to 2×10 -1 up to 5×10 -5 Pa. The implantation energy of controlled ions is 50-100keV, and the implantation dose is 1.0×10 17 to 5.0×10 17 ion / cm 2 , so that the lower surface of the ion implantation layer is located at a depth of 5-50 nm below the surface of the glass.

[0080] In the plasma deposition process, ZnO is still selected as the vacuum cathode arc target, the plasma deposition energy is controlled to be 1-1000eV, and a plasma deposition layer wi...

Embodiment 2

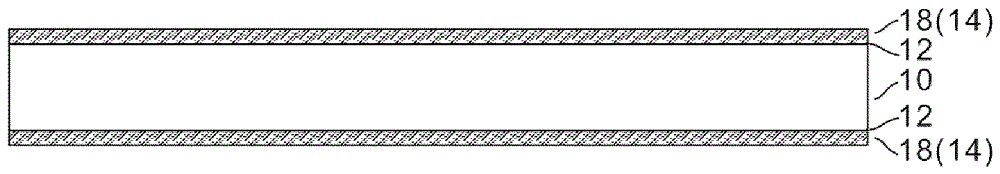

[0083] This embodiment relates to a metal oxide-doped transparent conductive film of a binary system.

[0084] First, a PI film with a thickness of 6-200 μm is selected as the transparent substrate. Then, a first conductive layer and a second conductive layer are sequentially formed on the surface of the PI film, wherein the first conductive layer is ZnO with a thickness of 5-500nm, and the second conductive layer is Al or Ag with a thickness of 5-500nm.

[0085] When preparing the first conductive layer (ZnO), a treatment method of first ion implantation and then plasma deposition is adopted. In the ion implantation process, ZnO was selected as the target material, the process temperature of the ion implantation was controlled to be 600°C, and the vacuum was evacuated to 2×10 -1 up to 5×10 -5 Pa. The implantation energy of controlled ions is 50-100keV, and the implantation dose is 1.0×10 17 to 5.0×10 17 ion / cm 2 , so that the lower surface of the ion implantation layer ...

Embodiment 3

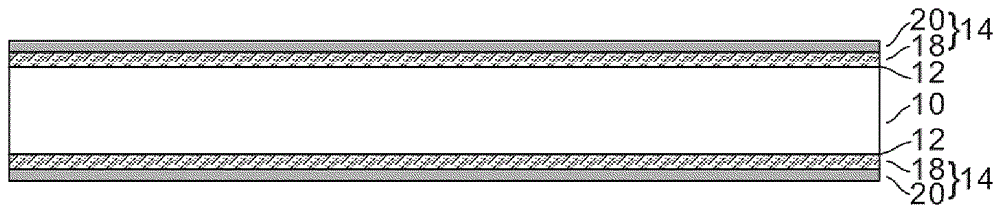

[0089] This embodiment relates to a metal oxide-doped transparent conductive film of a ternary system.

[0090] First, a PET film with a thickness of 10-200 μm is selected as the transparent substrate. Then, a first conductive layer and a second conductive layer are sequentially formed on the surface of the PET film, wherein the first conductive layer is MgO 2 -TiO 2 The doping structure, the second conductive layer is In 2 o 3 .

[0091] In the preparation of the first conductive layer (MgO 2 -TiO 2 ), choose MgO 2 -TiO 2 The target is used as a vacuum cathode arc target, and the treatment method is ion implantation followed by plasma deposition. The target is prepared by high-temperature sintering method, that is, MgO with an average particle size of 1 μm or less 2 Powder and TiO 2 The powders are blended and granulated at an atomic ratio of 1:1 in a high-temperature furnace, and a certain pressure (8ton / cm 2 ) to shape the produced powder, and then introduce oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com