Water-soluble granular fertilizer and preparation method thereof

A water-soluble granule and solubility technology, applied in the direction of alkaline orthophosphate fertilizers, nitrogen fertilizers, phosphate fertilizers, etc., can solve the problems that water-soluble fertilizers are prone to dust, difficult to achieve mechanical spreading, and short disintegration time, etc., and achieve low cost , short disintegration time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

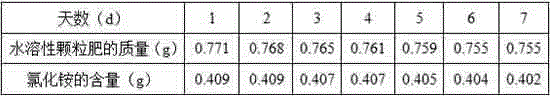

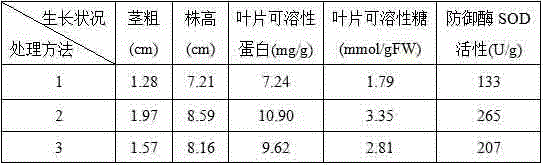

[0030] Embodiment 1 Preparation of water-soluble granular fertilizer

[0031] 1. A water-soluble granular fertilizer, comprising the following components in mass percentage: 50% ammonium chloride, 4% potassium dihydrogen phosphate, 34% sodium sulfate, 2% sodium humate, and 10% dextrin.

[0032] 2, the preparation method of described water-soluble granular fertilizer comprises the steps:

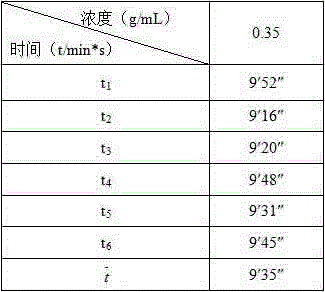

[0033] S1. Put the dextrin in boiling purified water, stir and dissolve it with a glass rod to make a slurry with a solubility c=0.35g / mL, and obtain a dextrin slurry;

[0034] S2. Granulation: Accurately weigh ammonium chloride, sodium dihydrogen phosphate, and sodium sulfate, mix them in a mortar and grind them, and pass through a 100-mesh sieve;

[0035] S3. Put the mixture obtained in step S2 into a beaker, add sodium humate to reconcile the mixture, add the prepared dextrin slurry in step S1 to make a soft material;

[0036] S4. Pass through a 14-mesh sieve, dry at 58°C for 2 hours, an...

Embodiment 2

[0038] Example 2 Preparation of water-soluble granular fertilizer

[0039] 1. A water-soluble granular fertilizer comprising the following components in mass percentage: 40% ammonium chloride, 5% potassium dihydrogen phosphate, 40% sodium sulfate, 3% sodium humate, and 12% dextrin.

[0040] 2. The preparation method of the water-soluble granular fertilizer is the same as in Example 1.

Embodiment 3

[0041] Example 3 Preparation of water-soluble granular fertilizer

[0042] 1. A water-soluble granular fertilizer comprising the following components in mass percentage: 60% ammonium chloride, 3% potassium dihydrogen phosphate, 30% sodium sulfate, 1% sodium humate, and 6% dextrin.

[0043] 2. The preparation method of the water-soluble granular fertilizer is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com