A liquid composite oil phase for emulsion explosives and its preparation method

A technology of compound oil phase and emulsion explosive, which is applied to explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of reducing the number of online personnel of emulsion explosives, increasing the weighing of emulsifiers, feeding procedures, etc. The effect of reducing the number of people online, reducing energy consumption, and improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

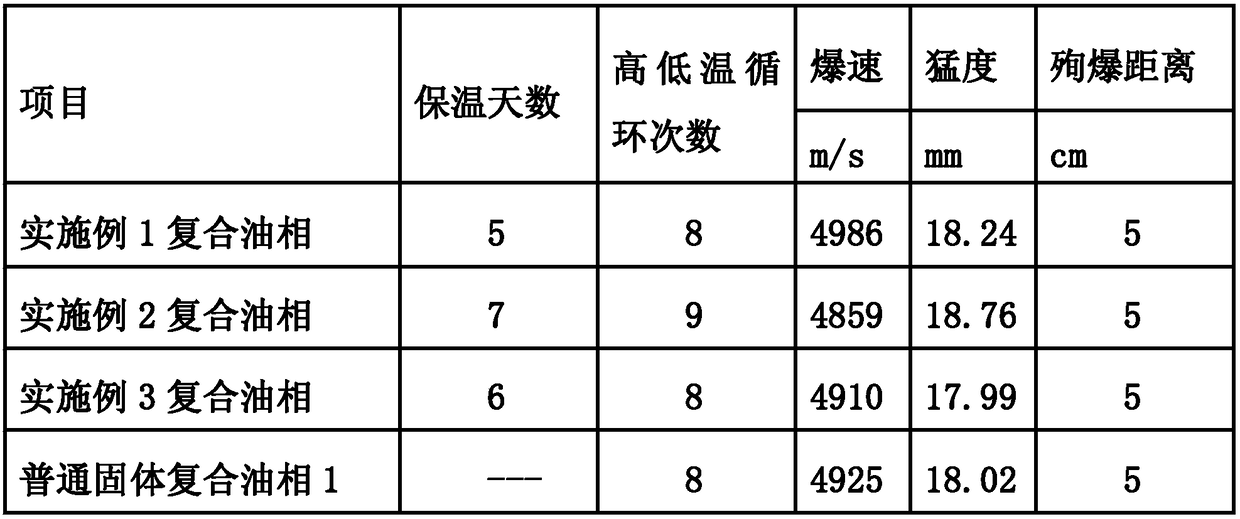

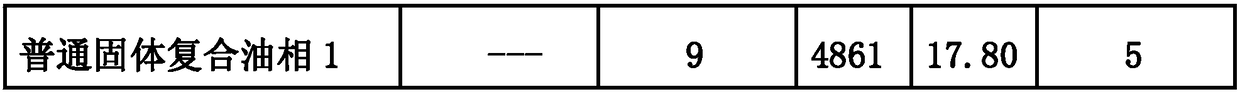

Examples

Embodiment 1

[0035] Embodiment 1: The component of composite oil phase and mass fraction thereof are: 32 parts of composite waxes, 20 parts of microcrystalline waxes, 32 parts # 10 parts of machine oil, 20 parts of Span-8020, 10 parts of polyisobutylene succinic acid ethanolamide (prepared by compounding polyisobutylene succinic anhydride and ethanolamine), 3 parts of palmitic acid.

[0036] Feed according to the components and quantities in the formula, first put in composite wax, microcrystalline wax, palmitic acid, after melting completely at 80-100°C, add 32 # Machinery oil, Span-80, polyisobutylene succinate ethanolamide, stirred evenly, filtered, then transported to the thermal insulation storage tank for storage, when used, directly transported to the thermal insulation tank of the emulsion explosive production line by oil tanker.

Embodiment 2

[0037] Embodiment 2: The components of the composite oil phase and their mass fractions are: 40 parts of composite wax, 15 parts of microcrystalline wax, 4 parts of 150SN base oil, 4 parts of 250SN base oil, 18 parts of diglycerol dioleate, poly 12 parts of triethanolamine isobutylene succinate, 1 part of palmitic acid, 1 part of dodecanoic acid.

[0038] According to the components and quantities in the formula, first put in composite wax, microcrystalline wax, palmitic acid, and dodecanoic acid. After melting completely at 80-100°C, add 150SN base oil, 250SN base oil, and diglycerin diol. Ester, triethanolamine polyisobutylene succinate, stirred evenly, filtered, then transported to the insulation storage tank for storage, when in use, directly transported to the insulation tank of the emulsion explosive production line by oil tanker.

Embodiment 3

[0039] Embodiment 3: the component of composite oil phase and mass fraction thereof are: 30 parts of composite wax, 22 parts of microcrystalline wax, 40 parts # 12 parts of machine oil, 25 parts of tripolyglycerol dioleate, 8 parts of polyisobutylene triethanolamine succinate, 3 parts of myristic acid.

[0040] Feed according to the components and quantities in the formula, first put in composite wax, microcrystalline wax, myristic acid, after melting completely at 80-100°C, add 40 #Machinery oil, tripolyglycerol dioleate, polyisobutylene succinate triethanolamine, after being stirred evenly, filtered, transported to the thermal insulation storage tank for storage, when used, directly transported to the emulsified explosive production line by tank truck Insulated tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com