Flame retardant nylon material and preparation method thereof

A technology of flame retardant nylon and flame retardant, which is applied in the field of polymer materials and their preparation, can solve the problems of poor flame retardant effect and poor dispersion of flame retardants, achieves low specific gravity, prevents flame spread, and reduces ignition effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

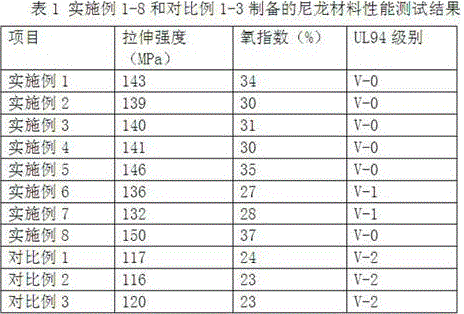

Examples

Embodiment 1

[0023] A flame-retardant nylon material, comprising the following raw materials in parts by weight: 200 parts of nylon 6, 40 parts of modified zinc borate, 40 parts of hexaphenoxycyclotriphosphazene, 0.5 part of antioxidant 1010, maleic anhydride grafted PE 6 parts, 1 part of silane coupling agent KH550.

[0024] Wherein, the preparation method of the modified zinc borate is that the zinc borate is put into a sodium hexadecylbenzenesulfonate solution with a mass concentration of 8%, heated and stirred for 10 hours, filtered with suction, and the filter cake is collected and washed 3 times with deionized water, Drying, naturally cooling to room temperature, crushing, and passing through a 200-mesh sieve to obtain modified zinc borate.

[0025] Its preparation method comprises the following steps:

[0026] (1) High-speed mixing of raw materials: put nylon 6, modified zinc borate, hexaphenoxycyclotriphosphazene, antioxidant 1010, maleic anhydride grafted PE, and silane coupling ...

Embodiment 2

[0029] A flame-retardant nylon material, comprising the following raw materials in parts by weight: 240 parts of nylon 6, 40 parts of modified zinc borate, 20 parts of hexaphenoxycyclotriphosphazene, 3 parts of antioxidant DLTP, maleic anhydride grafted PP 2 parts, 5 parts of silane coupling agent KH570.

[0030] Wherein, the preparation method of the modified zinc borate is that the zinc borate is put into a sodium hexadecylbenzenesulfonate solution with a mass concentration of 6%, heated and stirred for 12 hours, suction filtered, and the filter cake is collected and washed 5 times with deionized water, Dry, cool naturally to room temperature, pulverize, and pass through a 300-mesh sieve to obtain modified zinc borate.

[0031] Its preparation method comprises the following steps:

[0032] (1) High-speed mixing of raw materials: Put nylon 6, modified zinc borate, hexaphenoxycyclotriphosphazene, antioxidant DLTP, maleic anhydride grafted PP, and silane coupling agent KH570 i...

Embodiment 3

[0035] A flame-retardant nylon material, comprising the following raw materials in parts by weight: 210 parts of nylon 6, 38.2 parts of modified zinc borate, 31.8 parts of hexaphenoxycyclotriphosphazene, 1 part of antioxidant 168, maleic anhydride grafted PE 5 parts, 2 parts of silane coupling agent KH560.

[0036]Wherein, the preparation method of the modified zinc borate is that the zinc borate is put into a sodium hexadecylbenzenesulfonate solution with a mass concentration of 8%, heated and stirred for 11 hours, filtered with suction, and the filter cake is collected and washed 4 times with deionized water, Dry, cool naturally to room temperature, pulverize, and pass through a 250-mesh sieve to obtain modified zinc borate.

[0037] Its preparation method comprises the following steps:

[0038] (1) High-speed mixing of raw materials: put nylon 6, modified zinc borate, hexaphenoxycyclotriphosphazene, antioxidant 168, maleic anhydride grafted PE, and silane coupling agent KH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com