Composition for printing and spraying on ceramic surface and preparation and application methods thereof

A ceramic surface and composition technology, which is applied to the device, application, pretreatment surface, etc. of coating liquid on the surface, which can solve the problem of low curing speed of colored system, difficult curing in deep layers and shadow areas of objects, and the shape of the application substrate is limited. Limit and other problems, to achieve the effect of strong color rendering, fast curing speed, and saving energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

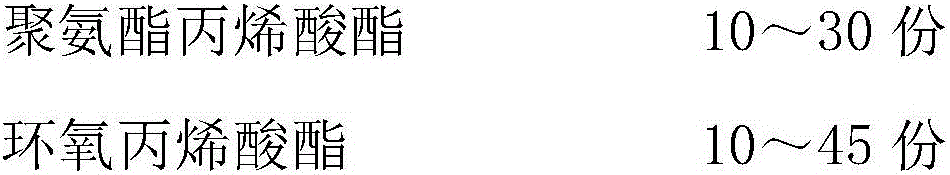

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

[0029] (one)

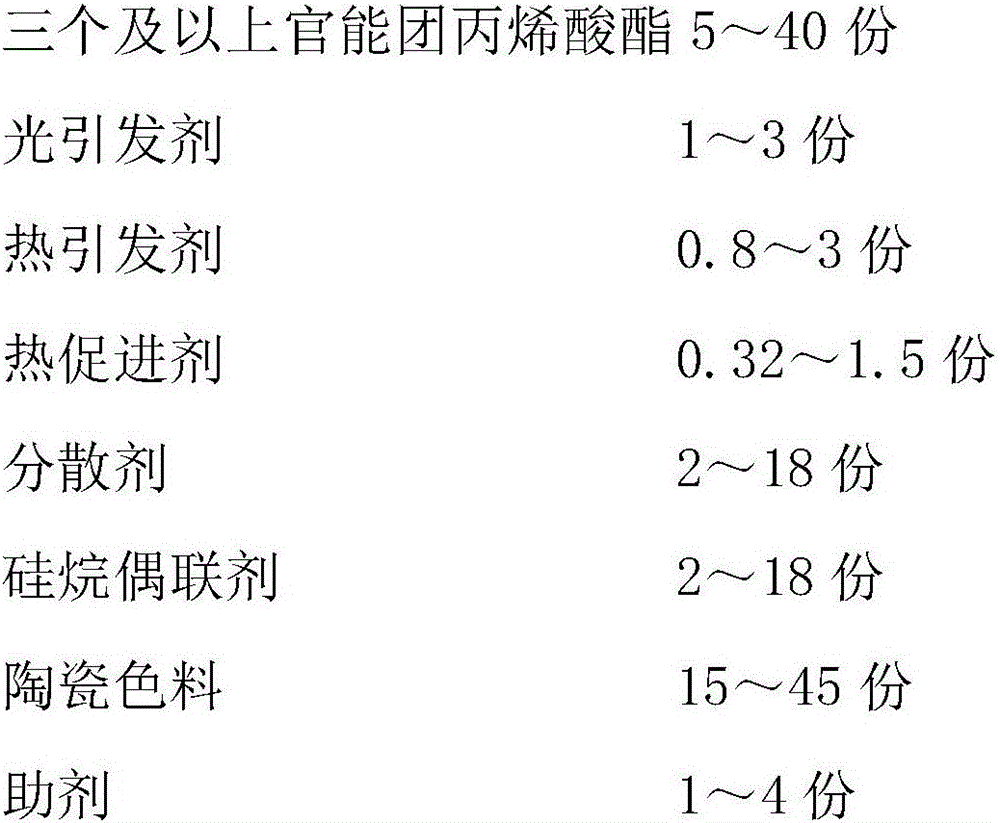

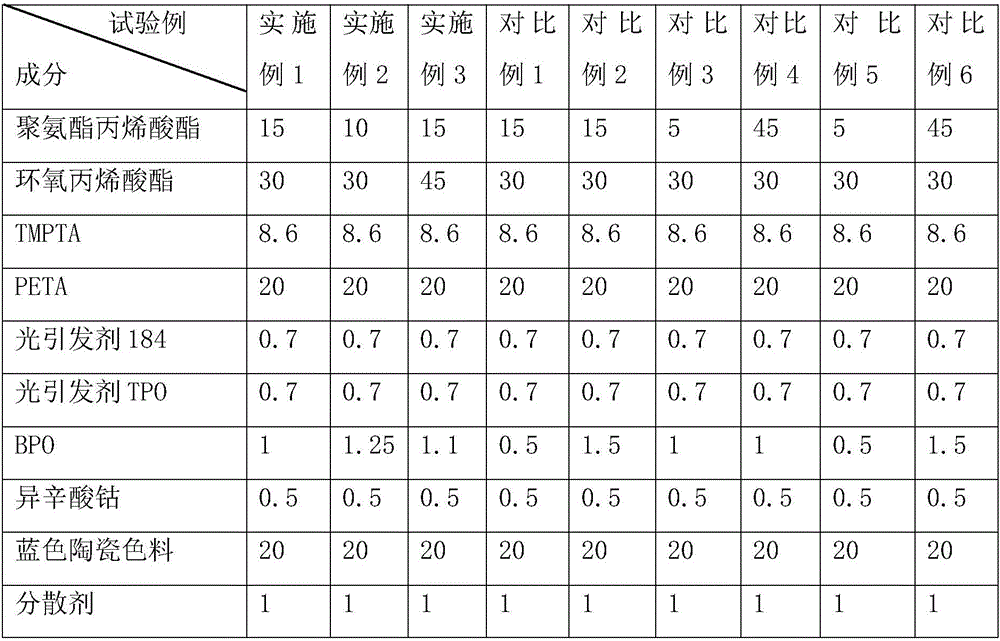

[0030] Prepare the blue composition according to the weight parts shown in Table 1, and the preparation method is as follows,

[0031] A) Preparation of color paste: Add leveling agent, defoamer, polymerization inhibitor, anti-sedimentation agent and dispersant to TMPTA and PETA mixture while stirring, mix evenly under high-speed stirring, and then slowly add blue ceramic colorant High-speed dispersion, so that the blue ceramic pigment is evenly dispersed to form a color paste;

[0032] B) Preparation of premixed liquid: under high-speed stirring, add silane coupling agent to the color paste, after mixing evenly, slowly add urethane acrylate and epoxy acrylate containing isocyanate groups, fully stir and mix, adjust the speed of the high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com