Microbial agent for tobacco and preparation method and application of microbial agent

A technology for microbial inoculants and cigarettes, applied in the application field of microbial technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Bacteria preparation

[0043] The freeze-dried tubes of Candida utilis and Bacillus subtilis strains were taken respectively for activation, and cultured on the inclined plane of test tubes and shake flasks to prepare microbial bacterial agents.

[0044] Potato culture medium is used for the slant and shake flask culture of Candida utilis, and the slant culture condition is 30° C. for 48 hours. Shake flask culture conditions: 30°C, 180r / min, 48 hours;

[0045] The slant and shake flask culture of Bacillus subtilis adopts the slant culture condition of beef extract peptone medium: 35°C, 24-36 hours. Shake flask culture conditions: 35°C, 180r / min, 24-48 hours.

[0046] Configure bacteria solution

[0047]Candida utilis and Bacillus subtilis were formulated into 2000 g of microbial inoculum at a mass ratio of 1:1, and a total content of 0.5% of inorganic salts was added.

[0048] Tobacco leaf spraying and fermentation

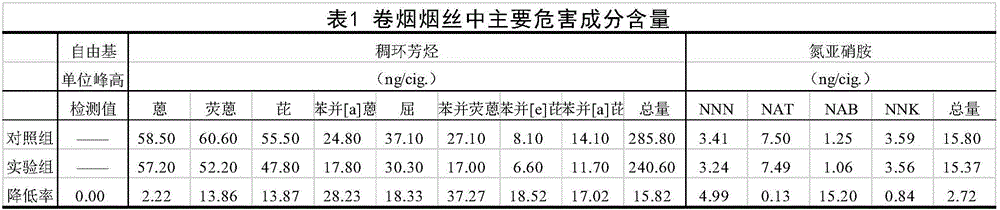

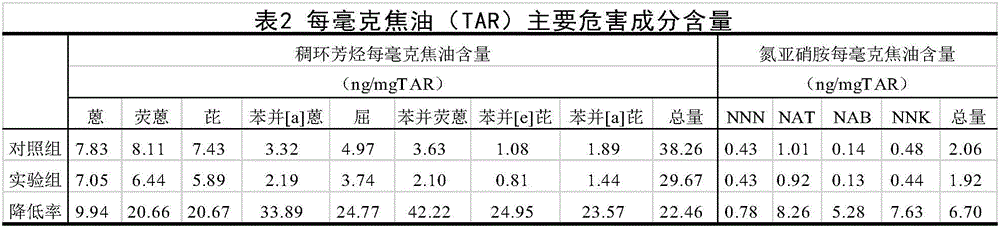

[0049] Spray 1000g of the above-mentioned microb...

Embodiment 2

[0056] Bacteria preparation

[0057] The freeze-dried tubes of Candida utilis and Bacillus subtilis strains were taken respectively for activation, and cultured on the inclined plane of test tubes and shake flasks to prepare microbial bacterial agents.

[0058] Potato culture medium is used for the slant and shake flask culture of Candida utilis, and the slant culture condition is 30° C. for 48 hours. Shake flask culture conditions: 30°C, 180r / min, 48 hours;

[0059] The slant and shake flask culture of Bacillus subtilis adopts the slant culture condition of beef extract peptone medium: 35°C, 24-36 hours. Shake flask culture conditions: 35°C, 180r / min, 24-48 hours.

[0060] Configure bacteria solution

[0061] Candida utilis and Bacillus subtilis were formulated into 2000 g of microbial inoculum at a mass ratio of 1:1, and a total content of 0.5% of inorganic salts was added.

[0062] Bacteria spraying and tobacco leaf fermentation

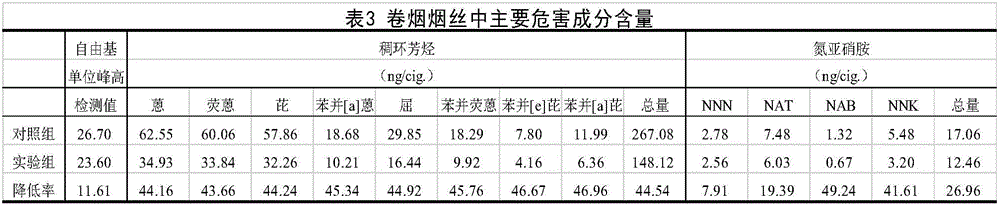

[0063] Spray 2000g of the above-mentio...

Embodiment 3

[0073] (1) Preparation of bacteria agent

[0074] The freeze-dried tubes of Candida utilis and Bacillus subtilis strains were taken respectively for activation, and cultured on the inclined plane of test tubes and shake flasks to prepare microbial bacterial agents.

[0075] Potato culture medium is used for the slant and shake flask culture of Candida utilis, and the slant culture condition is 30° C. for 48 hours. Shake flask culture conditions: 30°C, 180r / min, 48 hours;

[0076] The slant and shake flask culture of Bacillus subtilis adopts the slant culture condition of beef extract peptone medium: 35°C, 24-36 hours. Shake flask culture conditions: 35°C, 180r / min, 24-48 hours.

[0077] (2) Configure bacterial liquid

[0078] Candida utilis and Bacillus subtilis were formulated into 2000 g of microbial inoculum at a mass ratio of 2:1, and a total content of 0.5% of inorganic salts was added.

[0079] (3) Tobacco leaf spraying and fermentation

[0080] Spray 2000g of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com