High-purity compactin and process for producing same on large scale

A process and seed technology, applied in the field of medicine, to achieve the effects of increasing yield, increasing fermentation capacity, and increasing specific productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

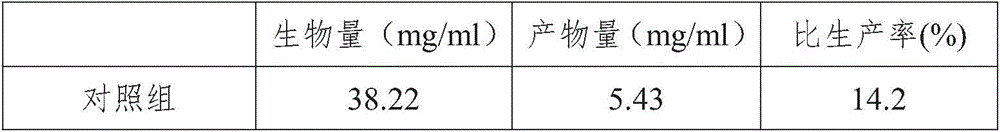

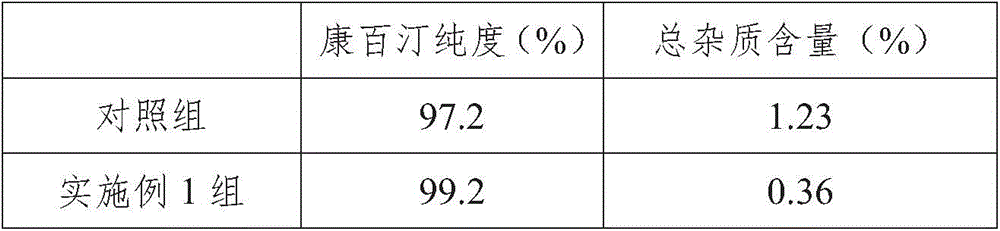

Examples

Embodiment 1

[0034] The seed culture medium is composed of the following components: white granulated sugar 45g / L, glycerol 30g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O 1g / L, vitamin solution 0.1ml / L, add water to 1L; vitamin solution consists of vitamin B10.03g / L, vitamin B 2 0.01g / L and vitamin C 0.05g / L.

[0035] The fermentation medium is composed of the following components: white granulated sugar 45g / L, glycerol 30g / L, soybean powder 5g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, plant extract 0.4g / L, add water to 1L; the plant extract is composed of Sophorae japonica extract and Emlica emblica extract in a volume ratio of 3:2.

[0036] The preparation technology of described Kang Baiting:

[0037] S1 Inoculate Penicillium citrinum in the above-mentioned seed medium for seed culture, and the culture conditions are as follows: temperature is 26°C, pressure is 0.04MPa, air flow rate is 0.5vvm, stirring speed is 100rpm, and the culture period is 62h; then inoculate Carry out ferment...

Embodiment 2

[0042] The seed culture medium is composed of the following components: white granulated sugar 52g / L, glycerol 40g / L, KH 2 PO 4 1.3g / L, MgSO 4 ·7H 2 O 1.2g / L, vitamin solution 0.3ml / L, add water to 1L; the vitamin solution is composed of vitamin B 1 0.08g / L, vitamin B 2 0.08g / L and vitamin C 0.1g / L.

[0043] The fermentation medium is composed of the following components: white granulated sugar 52g / L, glycerol 32g / L, soybean powder 7.5g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O 1g / L, plant extract 0.8g / L, add water to 1L; the plant extract is composed of Sophorae japonica extract and Emlica emblica extract in a volume ratio of 4:1.

[0044] The preparation process of said Compatin is similar to Example 1.

Embodiment 3

[0046] The seed culture medium is composed of the following components: white granulated sugar 55g / L, glycerol 50g / L, KH 2 PO 4 3g / L, MgSO 4 ·7H 2 O 2g / L, vitamin solution 0.4ml / L, water is added to 1L; The vitamin solution is composed of vitamin B 1 0.1g / L, vitamin B 2 0.1g / L and vitamin C 0.1g / L.

[0047] The fermentation medium is composed of the following components: white granulated sugar 55g / L, glycerin 40g / L, soybean powder 10g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, plant extract 1.2g / L, add water to 1L; the plant extract is composed of Sophora japonica extract and Emlica emblica extract in a volume ratio of 6:1.

[0048] The preparation process of said Compatin is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com