Method for in-situ synthesis of nano silver fabrics with aloe extracting liquid and prepared fabrics

An aloe vera extract and in-situ synthesis technology, which is applied in the fields of plant fiber, textiles, papermaking, fiber treatment, etc., can solve the problems that the content of nano-silver needs to be improved, and achieve enhanced anti-ultraviolet performance, antibacterial performance, and good washing resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of Aloe Vera Extract:

[0045] Take fresh aloe leaves, cut 120g of aloe mesophyll, add 80mL of distilled water, boil for 15 minutes, filter with suction, and save the filtrate, which is the aloe extract; the obtained aloe extract can be sealed and stored at low temperature to keep it fresh.

[0046] 2. Processing technology:

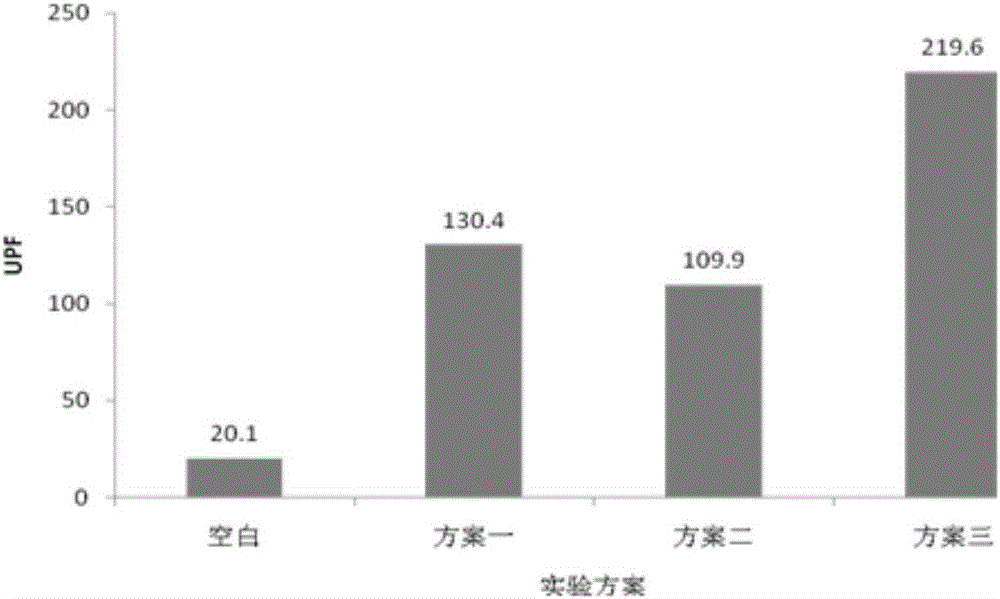

[0047] Option 1: Take 1g of cotton fabric and soak it in silver nitrate solution for 1 hour in the dark, with a bath ratio of 1:50.

[0048] Option 2: Take 1g of cotton fabric, soak in aloe extract for 30 minutes, with a bath ratio of 1:20, and dry at low temperature; soak in silver nitrate solution for 1 hour, with a bath ratio of 1:50, and dry in vacuum.

[0049] Scheme 3: Take 1g of cotton fabric and soak it in silver nitrate solution for 1 hour, avoid light reaction, bath ratio is 1:50, take out the cotton cloth after the reaction, and vacuum dry it for 1.5 hours; take out the cotton cloth and soak it in the aloe extract for 30...

Embodiment 2

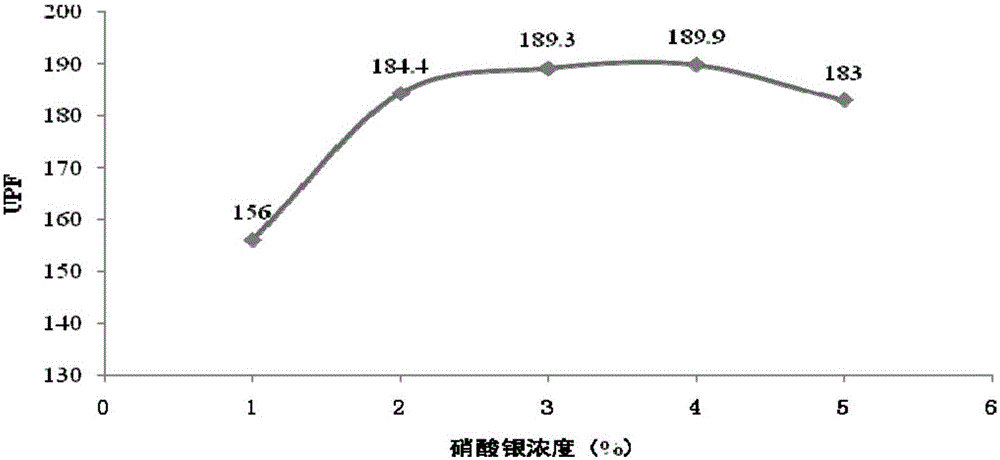

[0068] Test group: take a plurality of 1g cotton fabrics and soak them in silver nitrate solution with a mass concentration of 3% for 1 hour, and react in the dark with a bath ratio of 1:20. Take it out and soak it in the aloe extract at 40°C for 60min, the bath ratio is 1:15, take out the cotton cloth after the reaction is finished, and dry it at 60°C.

[0069] Control group: Untreated cotton fabric.

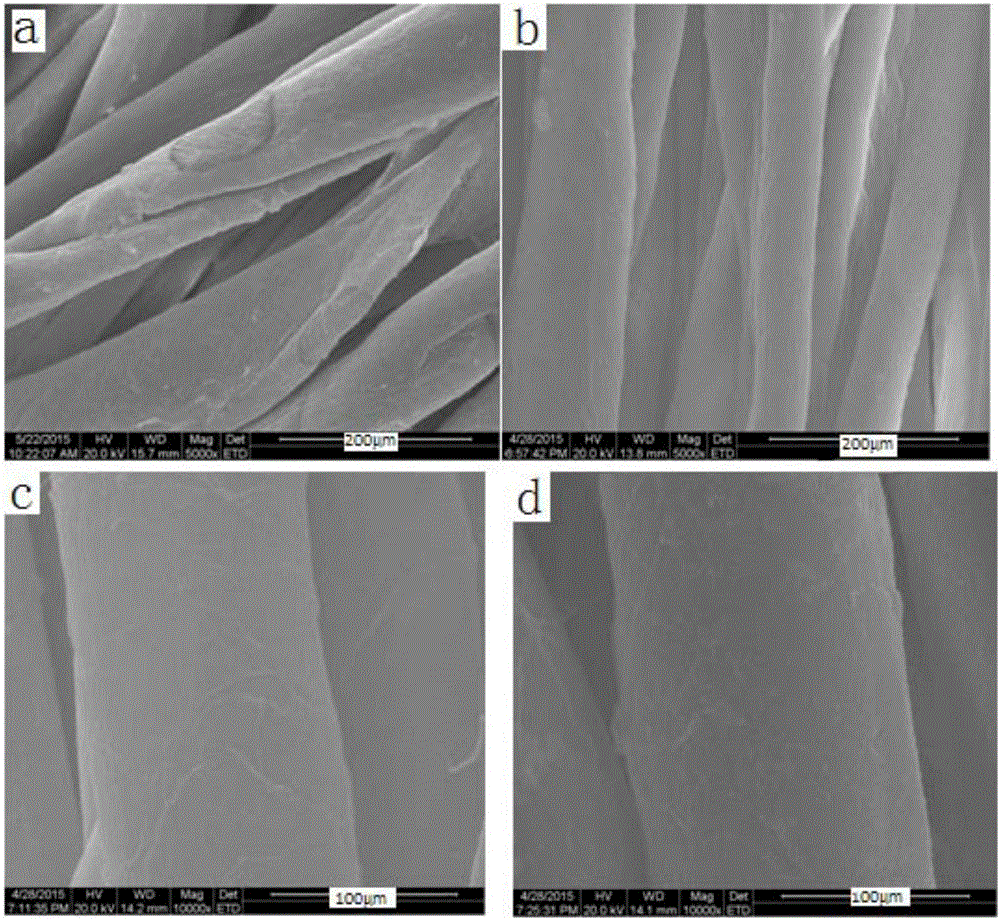

[0070] One, the cotton fabric that test group is processed and the untreated cotton fabric of control group are carried out electron microscope scanning, the result is as follows Figure 8 shown. Figure 8 The middle control group and the test group are the scanning electron micrographs of the blank cotton fabric and the same cotton fabric processed under the optimal process conditions respectively, Figure 8 The surface of the blank cotton fabric in the control group was smoother, while Figure 8 A large number of nanoparticles are attached to the treated cotton fabric, whi...

Embodiment 3

[0086] Group 1: Preparation of aloe extract: take fresh aloe leaves, cut 100 g of aloe mesophyll, add 80 mL of distilled water, boil for 15 minutes, filter with suction, and save the filtrate, which is the aloe extract;

[0087] Take 1g of cotton fabric and soak it in a silver nitrate solution with a mass concentration of 1% for 90 minutes, and react in the dark, with a bath ratio of 1:20. After the reaction, take out the cotton cloth and dry it under vacuum at 50°C; take out the cotton cloth and soak it in aloe vera at 40°C In the extract solution for 60 minutes, the liquor ratio is 1:15. After the reaction, take out the cotton cloth and dry it at 60°C.

[0088] Group 2: Preparation of aloe extract: take fresh aloe leaves, cut 120g of aloe mesophyll, add 80mL of distilled water, boil for 15min, filter with suction, and save the filtrate, which is the aloe extract;

[0089] Take 1g of cotton fabric and soak it in a silver nitrate solution with a mass concentration of 2% for 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com