Light-heavy segmental lining combined structure of TBM tunnel and design method thereof

A technology of combined structure and design method, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of economic loss, high reinforcement amount, waste, etc., and achieve the effect of simple calculation process and reduction of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

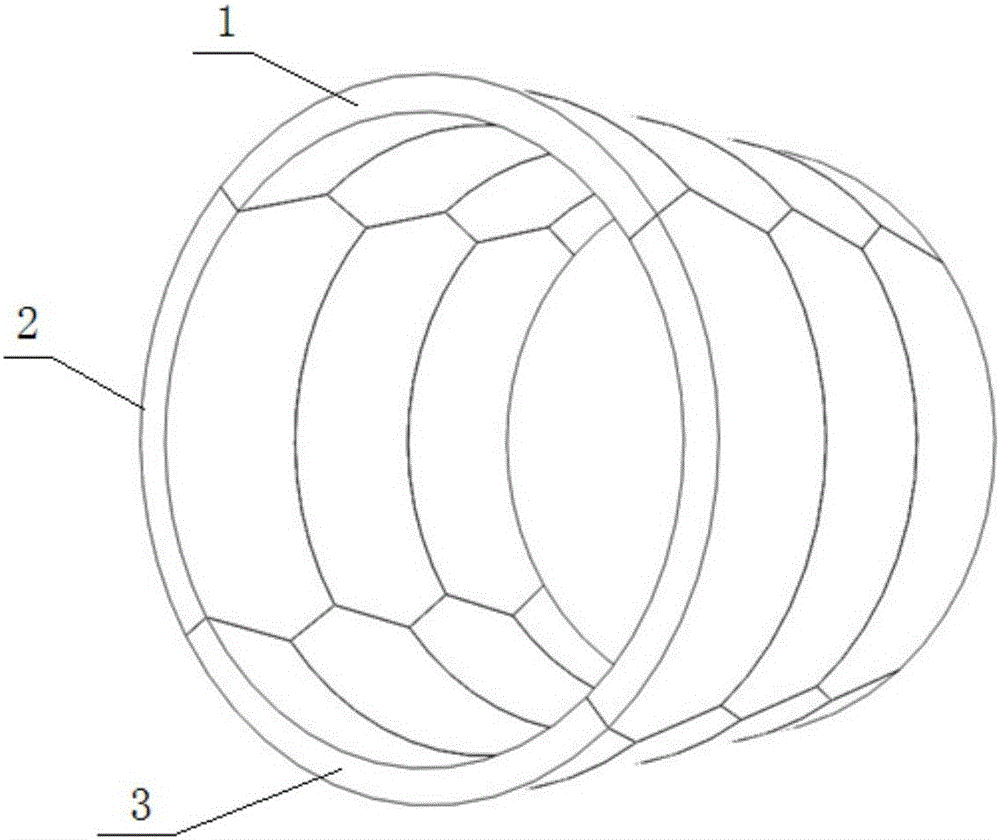

[0035] A combined light and heavy segment lining structure for tunnels, including tunnel lining segments, the lining segments in at least one section of the tunnel section are arranged in the following structure: in the same ring lining segment, segments at different positions along the tunnel ring , their reinforcement ratios are not exactly the same. Such as figure 1 As shown, the shield segment includes the top segment 1, the two side segments 2 and the bottom segment 3. When the lateral pressure coefficient of the surrounding rock is 0.7-0.9, the reinforcement ratio of the top segment 1 is different from that of the two side segments The ratio of the reinforcement ratio of 2 is 1.1-1.3; when the lateral pressure coefficient is 1.1-1.3, the ratio of the reinforcement ratio of the top segment 1 to the reinforcement ratio of the two side segments 2 is 0.6-0.9; when the lateral pressure When the coefficient is 1.3-1.5, the ratio of the reinforcement rate of the top segment 1 ...

Embodiment 2

[0069] Daban Tunnel uses this design scheme. At the beginning of the design, in order to adapt to different geological conditions and minimize the cost of concrete prefabricated segments, A-1, A, B, C, C-1, and C-2 were designed according to different surrounding rock types and external water conditions. , D and E type 8 kinds of prefabricated reinforced concrete segments, and configure different amounts of steel bars according to the different use conditions of each segment. The diameters of grade I steel bars used in steel bars are 6.5, 8, 10mm, and the diameters of grade II steel bars are 10, 12, 14, 16, 18, 20, 22mm. The service conditions and reinforcement ratios of 8 different segment types:

[0070] Type A-1 segment——suitable for drilling and blasting excavation of soil tunnel TBM sliding tunnel section and type II segment lining of rock cave without outer water surrounding, the design reinforcement rate is 83.34kg / m3 (85.28kg / m3) .

[0071] Type A segment—applicable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com