Power semiconductor device internal contact thermal resistance measurement method and measurement clamp

A technology of power semiconductor and measurement method, which is applied in the direction of single semiconductor device testing, measurement of electrical variables, measurement of electricity, etc., can solve the problems of difficulty in meeting the requirements of roughness and actual working conditions, destroying the phase relationship, and difficulty in guaranteeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

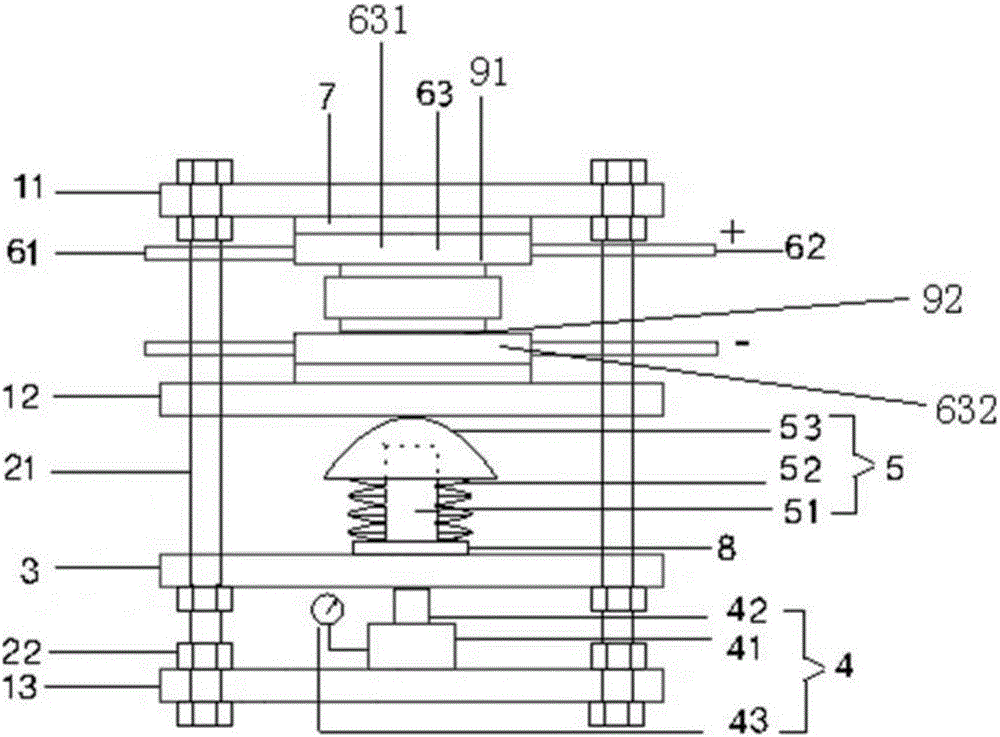

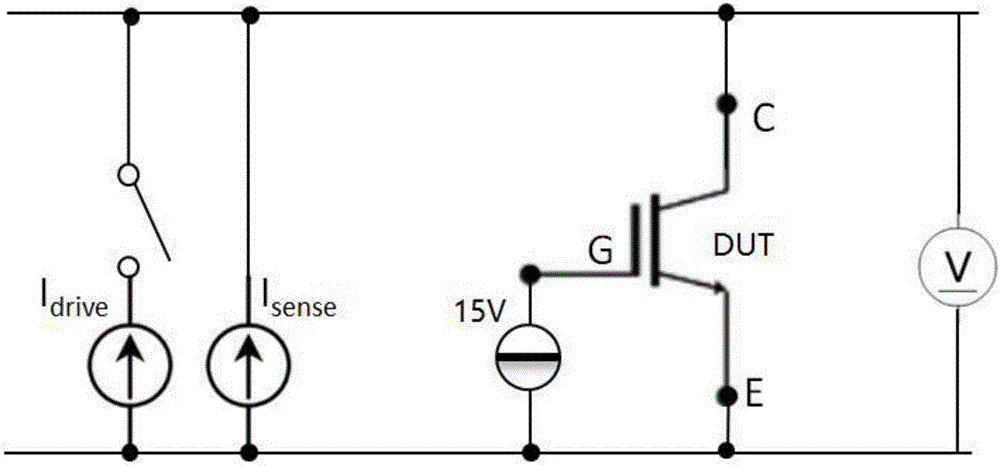

[0067] In order to describe the measurement scheme in the technical scheme provided by the present invention in more detail, it will be further described below in conjunction with the accompanying drawings and specific implementations.

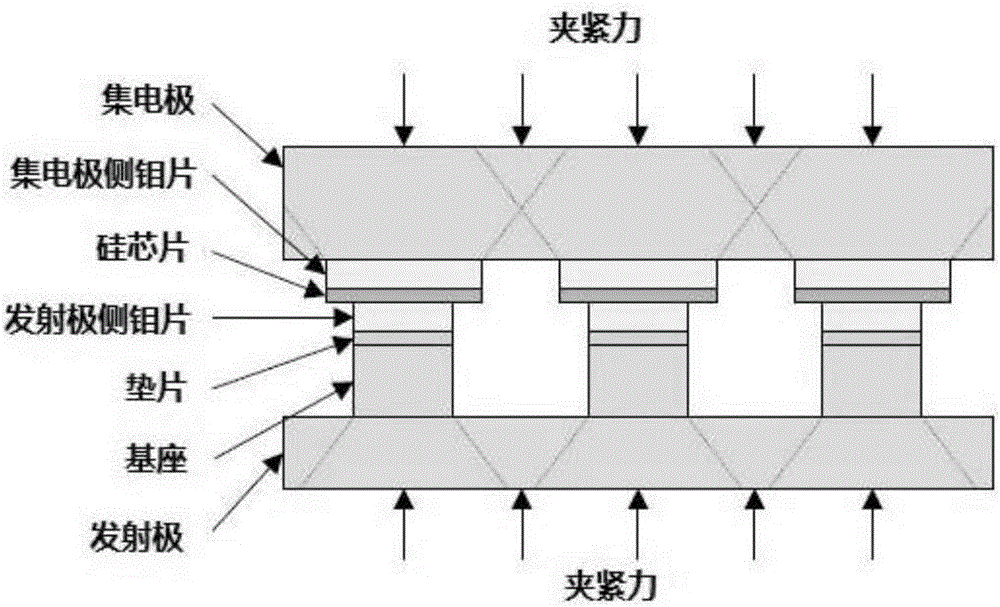

[0068] The structural schematic diagram of the existing IGBT crimping device is as follows: figure 1 As shown, it includes the collector, the molybdenum sheet on the collector side, the silicon chip, the molybdenum sheet on the emitter side, the spacer, the base, and the emitter in sequence. The number of internal components contained is large, and the area is relatively large and the thickness of each device is thin. , is mm level, in order to ensure the accurate measurement of the internal thermal contact resistance of the IGBT crimping device without damaging the integrity and excellent performance of the device, the present invention uses a measuring fixture to measure the internal thermal contact resistance to ensure that the devices are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com