Method for raising nucleation temperatures of citrus juice freeze-concentrated crystals by utilizing synergistic effects of ice nucleation protein-ultrasonic waves

An ice-nucleating protein and freeze-concentration technology, which is applied in food ultrasonic treatment, food freezing, and protein-containing food ingredients, can solve the problems of high energy consumption, low requirements for crystallization nucleation temperature, and low product yield. Less energy, shorter processing time, and high concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

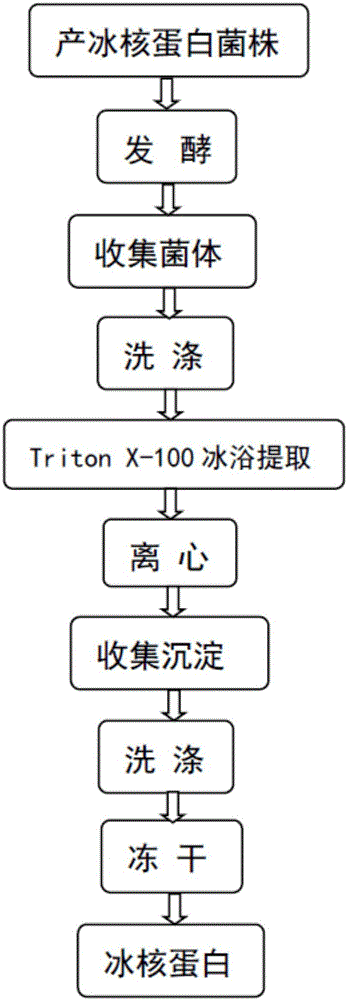

Method used

Image

Examples

Embodiment 1

[0032] a) Dissolving the ice nucleation protein in 14Brix citrus juice, the final concentration of the ice nucleation protein in the citrus juice is 10 μg / mL;

[0033] b) Pump the citrus juice into the plate heat exchanger, pre-cooling and cooling down to 4-6°C;

[0034] c) The pre-cooled citrus juice is pumped into the jacketed heat exchanger, and the temperature is rapidly lowered to within the range of -3 to -10°C;

[0035] d) Pump the citrus juice after precooling again into the jacketed crystallization tank, apply an ultrasonic wave with a frequency pole current of 0.3A, the ultrasonic frequency is 25MHz, and the ultrasonic treatment time is 2min, and at the same time, appropriate stirring is applied to carry out rapid freezing and concentration. The nucleation temperature was determined to be -6.8°C. Compared with Comparative Example 1, the ice crystal nucleation temperature increased by 1.7°C; compared with Comparative Example 2, the ice crystal nucleation temperature i...

Embodiment 2

[0037] a) Dissolving the ice nucleation protein in 14Brix citrus juice, the final concentration of the ice nucleation protein in the citrus juice is 15 μg / mL;

[0038] b) Pump the citrus juice into the plate heat exchanger, pre-cooling and cooling down to 4-6°C;

[0039] c) The pre-cooled citrus juice is pumped into the jacketed heat exchanger, and the temperature is rapidly lowered to within the range of -3 to -10°C;

[0040] d) Pump the citrus juice after precooling again into the jacketed crystallization tank, apply an ultrasonic wave with a frequency pole current of 0.3A, the ultrasonic frequency is 25MHz, and the ultrasonic treatment time is 2min, and at the same time, appropriate stirring is applied to carry out rapid freezing and concentration. The nucleation temperature was determined to be -6.5°C. Compared with Comparative Example 1, the ice crystal nucleation temperature increased by 2.0°C; compared with Comparative Example 2, the ice crystal nucleation temperature i...

Embodiment 3

[0042] a) Dissolving the ice nucleation protein in 14Brix citrus juice, the final concentration of the ice nucleation protein in the citrus juice is 20 μg / mL;

[0043] b) Pump the citrus juice into the plate heat exchanger, pre-cooling and cooling down to 4-6°C;

[0044] c) The pre-cooled citrus juice is pumped into the jacketed heat exchanger, and the temperature is rapidly lowered to within the range of -3 to -10°C;

[0045] d) Pump the citrus juice after precooling again into the jacketed crystallization tank, apply an ultrasonic wave with a frequency pole current of 0.3A, the ultrasonic frequency is 25MHz, and the ultrasonic treatment time is 2min, and at the same time, appropriate stirring is applied to carry out rapid freezing and concentration. The nucleation temperature was determined to be -6.3°C. Compared with Comparative Example 1, the ice crystal nucleation temperature increased by 2.2°C; compared with Comparative Example 2, the ice crystal nucleation temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com