Potato rice flour without adding exogenous moisture and preparation method thereof

A production method and potato technology, which are applied in the field of food processing, can solve the problems of high water content of fresh potatoes and difficulty in increasing the addition ratio, and achieve the effects of increasing consumption, improving production efficiency and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

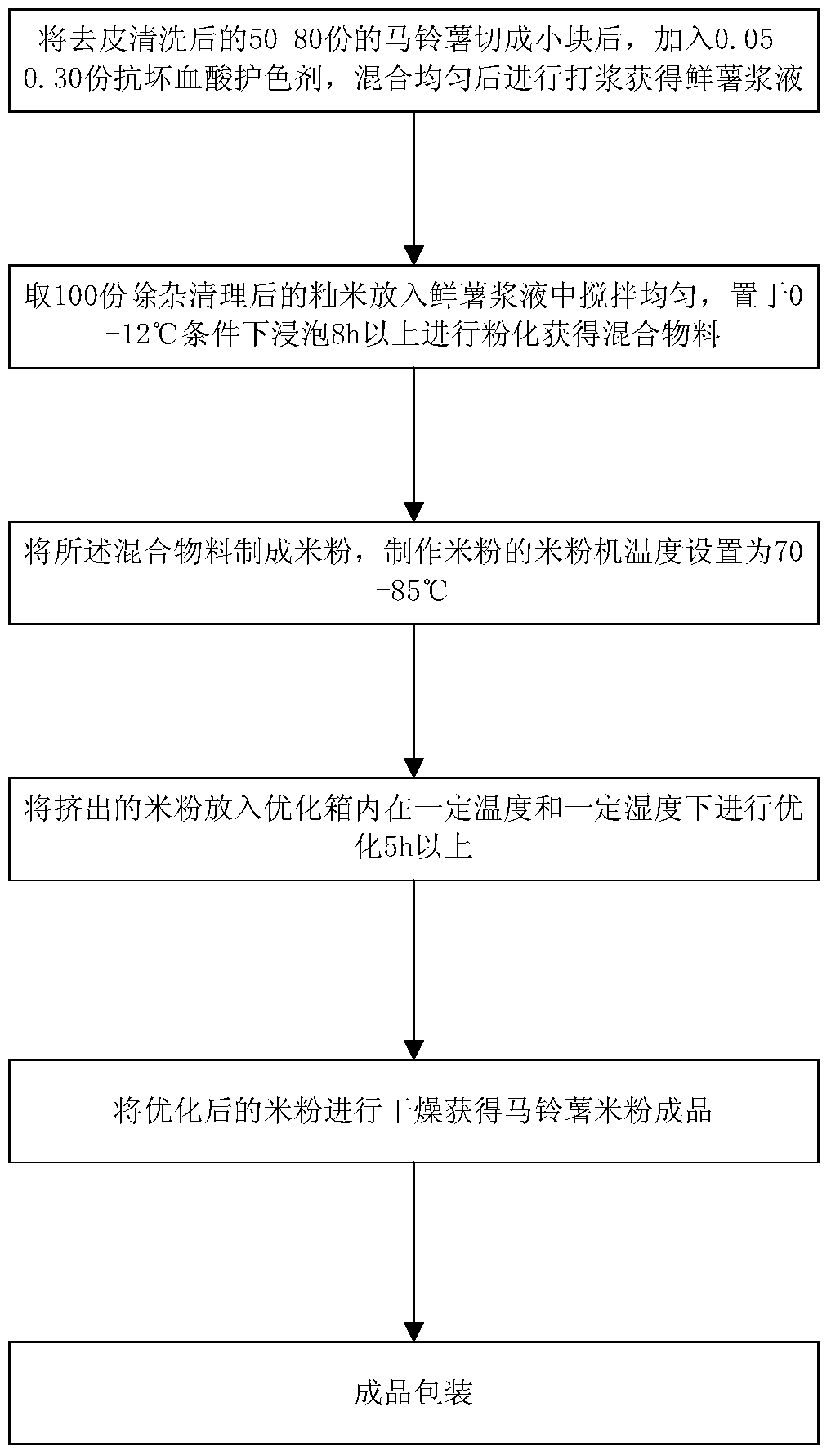

[0053] A kind of preparation method of the potato rice flour that does not add exogenous moisture, it is characterized in that, comprises the following steps:

[0054] Step 1. Cut the peeled and washed 50-80 parts of potatoes into small pieces by weight fraction, add 0.05-0.30 parts of ascorbic acid color-protecting agent, mix evenly, and beat to obtain fresh potato slurry;

[0055] Step 2: Take 100 parts of indica rice after removing impurities and cleaning it into fresh potato slurry, stir evenly, soak at 6°C for 8 hours, and pulverize to obtain a mixed material according to the weight fraction;

[0056] Step 3, the mixed material is made into rice flour, and the extrusion temperature of the rice flour machine for making rice flour is set to 70°C;

[0057] Step 4, put the extruded rice flour into the optimization box and optimize it for 5 hours at a certain temperature and humidity;

[0058] Step 5, drying the optimized rice flour to obtain the finished potato rice flour.

...

Embodiment 2

[0068] A kind of preparation method of the potato rice flour that does not add exogenous moisture, it is characterized in that, comprises the following steps:

[0069] Step 1. Cut 60 parts of peeled and washed potatoes into small pieces by weight fraction, add 0.05-0.30 parts of ascorbic acid color-protecting agent, mix well, and beat to obtain fresh potato slurry;

[0070] Step 2: Take 100 parts of indica rice after cleaning by weight and put it into the fresh potato slurry, stir evenly, soak at 12°C for 10 hours, and pulverize to obtain the mixed material;

[0071] Step 3, the mixed material is made into rice flour, and the extrusion temperature of the rice flour machine for making rice flour is set to 85°C;

[0072] Step 4, put the extruded rice flour into the optimization box and optimize it for 8 hours at a certain temperature and humidity;

[0073] Step 5, drying the optimized rice flour to obtain the finished potato rice flour.

[0074] In a preferred version, in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com